Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, the kitchen appliances industry has witnessed a surge in innovation, with a particular spotlight on air fryers. These appliances have become increasingly popular for their ability to offer healthier cooking options while maintaining the delicious flavors of traditional fried foods. As the market evolves, the importance of quality, safety, and efficiency cannot be overstated. This article delves into the dynamic world of air fryer OEM production, exploring the innovative concepts shaping the industry, the role of turnkey solutions, and the benefits of partnering with a UL certified manufacturer. By understanding these aspects, we can glimpse the future of kitchen appliances and how they are poised to revolutionize the culinary landscape.

In recent years, the kitchen appliance industry has seen a remarkable shift in consumer preferences, with air fryers emerging as a favorite among health-conscious home cooks and culinary enthusiasts. This surge in popularity can be attributed to several factors that have converged to make air fryers a must-have item in modern kitchens.

The air fryer’s allure lies in its promise of crispy, fried food without the guilt. By circulating hot air around food, these devices achieve a similar texture to traditional deep-frying while using a fraction of the oil. This health-conscious approach is particularly appealing to the growing number of individuals looking to reduce their fat and calorie intake without sacrificing taste.

One of the key drivers behind the air fryer’s popularity is the rise of wellness and fitness trends. As more people adopt a healthier lifestyle, they are actively seeking out cooking methods that align with their dietary goals. The air fryer fits perfectly into this narrative, offering a convenient way to prepare delicious meals that are both nutritious and satisfying.

Additionally, the convenience factor cannot be overlooked. Air fryers are compact, easy to use, and require minimal clean-up. They can be used to cook a wide variety of foods, from French fries and chicken wings to vegetables and desserts. This versatility has made air fryers a staple in households across the globe.

The market for air fryers has seen exponential growth, with sales skyrocketing in recent years. According to market research reports, the global air fryer market is expected to reach a significant value by 2025, driven by factors such as increasing health awareness, technological advancements, and the growing preference for smart kitchen appliances.

One of the most notable technological advancements in air fryers is the integration of smart features. Modern air fryers often come with programmable settings, timers, and even Wi-Fi connectivity, allowing users to control their appliances remotely. These features not only enhance the convenience of cooking but also provide users with the ability to experiment with different recipes and cooking times.

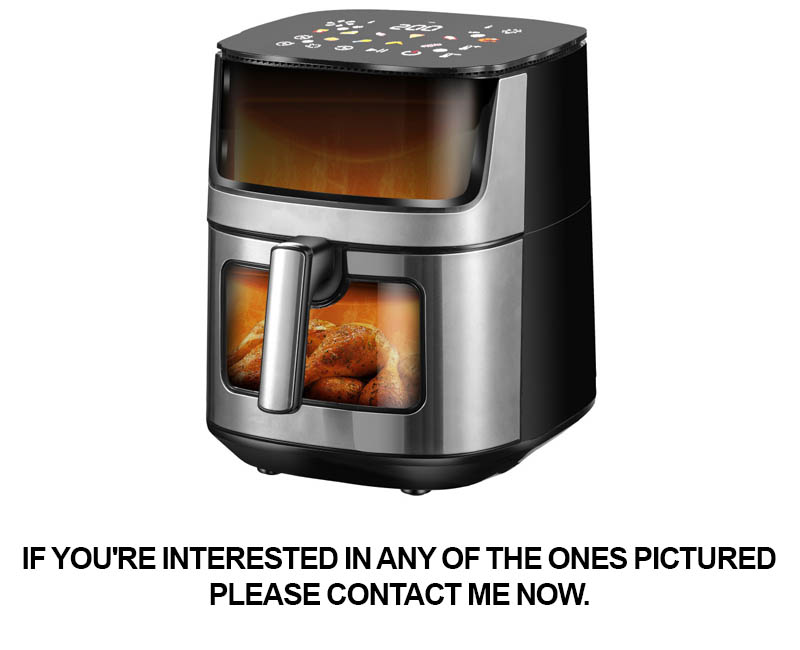

The trend towards air fryers has also spurred innovation in the kitchen appliance industry. Manufacturers are continuously working to improve the design and functionality of air fryers, offering models with additional features such as extra-large capacities, multiple cooking baskets, and even built-in air filters to reduce odors. This competition has led to a wide array of options for consumers, catering to different budgets and preferences.

From a business perspective, the rise of air fryers presents a significant opportunity for manufacturers and retailers. The demand for these appliances has opened up new markets and created a niche for specialized products. This trend has also encouraged the development of turnkey solutions, which are becoming increasingly popular among Original Equipment Manufacturers (OEMs).

Turnkey solutions refer to complete packages that include design, production, testing, and certification, all under one roof. This approach is particularly beneficial for OEMs looking to enter the air fryer market quickly and efficiently. By partnering with a turnkey UL certified air fryer manufacturer, OEMs can leverage the expertise of the provider to ensure their products meet the highest safety standards and regulatory requirements.

The UL (Underwriters Laboratories) certification is a globally recognized symbol of safety and quality. By obtaining this certification, air fryer manufacturers can assure consumers that their products have undergone rigorous testing to meet specific safety standards. This certification is not only a testament to the product’s quality but also a key factor in building consumer trust and confidence.

In conclusion, the rise of air fryers in the kitchen appliance market is a testament to the evolving preferences of consumers and the technological advancements that enable healthier, more convenient cooking methods. As the market continues to grow, the demand for turnkey solutions and products with UL certification will likely increase, further shaping the landscape of the air fryer industry.

In today’s fast-paced world, where convenience and health consciousness go hand in hand, the demand for kitchen appliances that cater to both has surged. Among these, air fryers have emerged as a standout product, promising a healthier alternative to traditional frying methods. However, for consumers to trust these appliances, they must meet stringent safety and quality standards. This is where UL certification plays a pivotal role.

The Underwriters Laboratories (UL) is a globally recognized organization that sets safety standards for a wide range of products. When it comes to air fryers, UL certification is not just a label—it’s a testament to the product’s adherence to safety protocols and performance benchmarks. Let’s delve into why this certification is so crucial.

Firstly, UL certification ensures that the air fryer has been tested for electrical safety. This includes checking for the presence of any exposed wires, proper grounding, and the appliance’s ability to handle electrical surges without causing harm. With kitchen appliances, electrical safety is paramount, as they are often used in close proximity to water and food, which can increase the risk of accidents.

Secondly, the certification process scrutinizes the construction and materials used in the air fryer. This means that the appliance is built to withstand heat and potential impact, reducing the likelihood of malfunction or injury. From the outer casing to the inner components, every part must meet the strict standards set by UL to earn that coveted certification mark.

Moreover, UL certification also covers the appliance’s thermal and fire safety. Air fryers can reach high temperatures, and if not designed correctly, they could pose a fire hazard. The certification process ensures that the air fryer has adequate heat dissipation and that its components are flame-resistant, minimizing the risk of a kitchen fire.

Another critical aspect of UL certification is the evaluation of the appliance’s energy efficiency. Consumers are increasingly looking for products that are not only safe but also environmentally friendly. A UL-certified air fryer is likely to be more energy-efficient, which can lead to lower utility bills and a smaller carbon footprint.

In addition to safety and efficiency, UL certification also addresses user-friendliness. The certification process includes testing for user interfaces, controls, and instructions. This ensures that the air fryer is easy to operate, even for those who might not be tech-savvy. Clear and concise instructions, along with intuitive controls, are essential for a positive user experience.

Furthermore, the certification process involves rigorous testing for durability and performance. The air fryer must be able to maintain consistent cooking temperatures and perform its intended functions over an extended period without failing. This durability is a key factor in the longevity of the appliance and the satisfaction of the consumer.

For manufacturers, achieving UL certification is not just about compliance; it’s about building trust with consumers. The UL mark is recognized worldwide, and it carries a significant weight in the marketplace. A product with this certification is more likely to be picked off the shelf by a consumer who values safety and quality.

Moreover, in the case of air fryers, which are often exported to various countries, UL certification can simplify the regulatory process. Many countries require or prefer products that carry internationally recognized safety certifications. Having UL certification can save manufacturers time and resources in navigating these different regulatory landscapes.

In conclusion, the importance of UL certification for air fryers cannot be overstated. It is a symbol of safety, efficiency, and quality that consumers look for when making purchasing decisions. For manufacturers, it is a mark of distinction that can set their products apart from the competition. In an industry where health and safety are paramount, the UL certification is not just a label—it’s a commitment to excellence.

Air fryers have revolutionized the way we cook, offering a healthier alternative to deep-frying. But within this ever-evolving market, there’s a surge of innovative product concepts that are pushing the boundaries of what these appliances can do. Let’s delve into some of the most fascinating ideas shaping the future of air fryer technology.

Smart Sensors and IoT Integration: One of the most promising innovations in air fryers is the integration of smart sensors and the Internet of Things (IoT). These sensors can monitor the cooking process and adjust the temperature and time settings automatically, ensuring that the food is perfectly cooked every time. The IoT connection means users can control their air fryers remotely, via an app on their smartphone, making it easier to manage meals even when they’re away from home.

Multi-Functional Cooking Modes: While traditional air fryers are great for crispy fried foods, newer models are expanding their capabilities. Some are now equipped with multiple cooking modes, such as roasting, baking, dehydrating, and even making yogurt. This versatility allows users to prepare a wider variety of dishes without the need for additional kitchen appliances.

Personalized Cooking Profiles: Recognizing that each household has unique preferences, some air fryer manufacturers are introducing personalized cooking profiles. These profiles can be programmed to suit different types of food and cooking styles, making it easier for users to achieve the perfect texture and flavor for their favorite recipes.

Eco-Friendly and Energy-Efficient Design: With growing environmental concerns, there’s a push for air fryers that are not only efficient but also eco-friendly. Innovators are exploring materials that are biodegradable or recyclable, as well as energy-saving features that reduce the appliance’s carbon footprint.

Healthier Cooking Options: Health-conscious consumers are always on the lookout for healthier cooking alternatives. New air fryer concepts are incorporating features that enhance the nutritional value of foods. For example, some models use steam to cook vegetables, preserving more of their vitamins and minerals than traditional boiling methods.

Sustainable and Local Ingredients: The next wave of air fryer innovation is focusing on sustainability. Manufacturers are exploring ways to use locally sourced and seasonal ingredients, which can be cooked quickly and efficiently in an air fryer. This not only supports local farmers but also reduces the carbon emissions associated with transporting food over long distances.

Interactive User Experience: Technology is making its way into kitchen appliances, and air fryers are no exception. Some models come with interactive displays that provide cooking tips, nutritional information, and even recipe suggestions. This adds an educational element to the cooking experience, making it more engaging for users.

Customizable Cooking Chambers: To cater to different dietary needs, some air fryer designs are focusing on customizable cooking chambers. These chambers can be adjusted to accommodate larger batches of food or to separate ingredients that might affect each other’s flavor, such as herbs and spices.

Advanced Filtration Systems: Air fryers are known for their ability to reduce oil content in cooking, but some models are taking this a step further with advanced filtration systems. These systems can trap even more grease and particulates, leading to cleaner, healthier cooking results.

Interactive Cooking Games: Finally, for those looking to add a fun element to cooking, there are air fryers that come with interactive cooking games. These games can teach users about different cooking techniques and times, making the learning process both entertaining and educational.

These innovative product concepts are not only redefining what air fryers can do but also setting the stage for a new era of smart, efficient, and health-conscious kitchen appliances. As technology continues to advance, we can expect even more exciting developments in the world of air fryers.

In the dynamic world of OEM (Original Equipment Manufacturing) production, turnkey solutions have become a cornerstone for companies looking to streamline their manufacturing processes and bring innovative products to market. Here’s how these comprehensive packages are reshaping the landscape of OEM production:

Efficiency in Design and DevelopmentTurnkey solutions offer a seamless blend of design and engineering expertise, ensuring that the OEM process is not only efficient but also innovative. By integrating design, prototyping, and production under one roof, these solutions reduce the time-to-market significantly, allowing OEMs to stay ahead of the competition with cutting-edge products.

Customization with PrecisionOne of the key benefits of turnkey solutions is the ability to offer highly customized products. From tailored air fryer features to unique branding, these services cater to the specific needs of clients. The precision in customization ensures that the final product not only meets market demands but also stands out in a crowded marketplace.

Quality Control Through Every StageQuality is paramount in OEM production, and turnkey solutions ensure that every stage of the manufacturing process adheres to stringent quality standards. From the selection of materials to the final assembly, these services guarantee that the air fryers are not only safe but also durable and reliable, which is crucial for building trust with consumers.

Supply Chain ManagementTurnkey solutions often come with robust supply chain management. This means that OEMs can rest assured that all components are sourced from reliable suppliers, minimizing the risk of delays and ensuring a steady flow of raw materials. This aspect is particularly important for air fryer production, where components like heating elements and fans are critical.

Cost-Effective ProductionBy consolidating all aspects of the manufacturing process, turnkey solutions can offer cost savings. This includes not just the direct costs of production but also the savings on time and resources. OEMs can avoid the overhead costs associated with managing multiple vendors and production lines, leading to more competitive pricing for their end products.

Regulatory ComplianceIn the fast-paced world of technology, regulatory compliance is non-negotiable. Turnkey solutions are designed with compliance in mind, ensuring that all air fryers meet necessary safety standards and certifications, such as the coveted UL (Underwriters Laboratories) certification. This not only protects the end consumer but also gives the OEM a competitive edge in the market.

ScalabilityThe nature of turnkey solutions allows for easy scalability. As an OEM’s business grows, these solutions can accommodate increased production volumes without compromising on quality or timelines. This flexibility is essential for adapting to market fluctuations and customer demands.

Innovation and Research and DevelopmentTurnkey solutions often include a dedicated R&D (Research and Development) component. This means that OEMs can tap into the latest innovations in air fryer technology without the need for their own in-house R&D team. This collaboration can lead to the creation of products that are not only efficient but also eco-friendly and health-conscious, catering to the evolving preferences of consumers.

Training and SupportThe turnkey approach also involves providing comprehensive training and support to the OEM’s staff. This ensures that the entire production process is understood and can be managed effectively. For air fryers, this might include understanding the intricacies of temperature control systems or the use of advanced cooking technologies.

Sustainability and Eco-Friendly PracticesIn today’s market, sustainability is a significant factor. Turnkey solutions can incorporate eco-friendly practices into the production process, from using recycled materials to reducing energy consumption during manufacturing. This not only appeals to environmentally conscious consumers but also positions the OEM as a forward-thinking brand.

ConclusionThe role of turnkey solutions in OEM production cannot be overstated. They provide a holistic approach to bringing air fryers and other products to market, offering efficiency, customization, quality control, cost-effectiveness, and regulatory compliance. By leveraging these comprehensive services, OEMs can focus on what they do best—marketing and selling their innovative products—while the turnkey provider takes care of the manufacturing intricacies.

In the bustling world of OEM (Original Equipment Manufacturer) production, the air fryer market has seen a surge of innovative projects that have not only captured consumer interest but also set new standards for appliance design and functionality. Let’s delve into a few successful air fryer OEM projects that have made waves in the industry.

One such project was a collaboration between a renowned appliance brand and a cutting-edge OEM manufacturer. The goal was to create an air fryer that not only offered the health benefits of frying with little to no oil but also integrated smart technology for user convenience. The result was a sleek, compact model with a digital interface that allowed users to track cooking times and temperatures, ensuring consistent results every time.

This project highlighted the importance of customization in OEM production. The OEM manufacturer was able to tailor the design to the brand’s specifications, incorporating their signature colors and logo, while also ensuring that the product met rigorous quality standards. The air fryer’s unique features, such as a detachable basket for easy cleaning and a built-in timer with a countdown function, were developed in close partnership with the appliance brand, ensuring that the final product was a true reflection of the brand’s values and consumer needs.

Another standout project was a collaboration between an established kitchenware company and an experienced OEM partner. This project focused on creating an air fryer that was not only efficient but also eco-friendly. The OEM team designed a model with an energy-saving mode and a non-toxic, recyclable housing, appealing to environmentally conscious consumers. The air fryer also featured a special “AirFry & Bake” mode, which allowed users to combine the air frying process with baking capabilities, expanding the device’s versatility.

The success of this project was a testament to the OEM manufacturer’s ability to innovate and adapt to market demands. By listening to the brand’s vision and the consumer’s needs, the OEM team was able to develop a product that balanced performance with sustainability. The air fryer was also equipped with a user-friendly interface and a recipe book, making it accessible to a broader audience who might be new to air frying technology.

A third notable project involved a global appliance company that sought to expand its product line with a premium air fryer. The OEM manufacturer was tasked with creating a high-end model that would appeal to consumers looking for the latest in kitchen appliances. The result was a sophisticated air fryer with a touch screen display, a variety of pre-programmed settings, and an advanced heating element that provided even cooking.

The OEM manufacturer faced the challenge of integrating premium materials without increasing the cost significantly. Through strategic sourcing and efficient production processes, they were able to deliver a high-quality product that met the brand’s expectations. The air fryer also came with a sleek, modular design that allowed for easy storage and integration into various kitchen environments.

These case studies illustrate the pivotal role that turnkey solutions play in OEM production. The ability of OEM manufacturers to work closely with brands to develop innovative, high-quality products is crucial in a market that is constantly evolving. From custom designs to cutting-edge technology, the successful air fryer OEM projects showcase the power of collaboration and the endless possibilities that arise when brands and manufacturers come together to push the boundaries of what’s possible in kitchen appliances.

Navigating the complexities of the kitchen appliances market, especially the air fryer sector, requires a keen eye for innovation and a solid understanding of compliance standards. Collaborating with a turnkey UL certified air fryer manufacturer can offer a multitude of benefits that can significantly enhance your product’s marketability and your business’s operational efficiency. Here’s a closer look at some of the key advantages:

Streamlined Production ProcessManufacturers that provide turnkey solutions handle the entire production process, from design and prototyping to assembly and quality control. This means that by partnering with such a manufacturer, you can eliminate the need for multiple suppliers and vendors, simplifying the supply chain and reducing the risk of delays and errors.

Quality Assurance and ComplianceA turnkey UL certified air fryer manufacturer is committed to adhering to stringent safety and quality standards. The UL certification ensures that the air fryers meet the highest safety standards set by Underwriters Laboratories, a globally recognized safety science company. This not only gives your product a competitive edge but also provides peace of mind to consumers who are looking for reliable and safe kitchen appliances.

Customization and FlexibilityTurnkey manufacturers often offer a high degree of customization, allowing you to tailor the air fryer to your brand’s specifications. This flexibility can be crucial in differentiating your product in a crowded market. Whether it’s a unique design, specific features, or branding elements, a turnkey manufacturer can help bring your vision to life.

Cost-Effective SolutionsOpting for a turnkey solution can lead to significant cost savings. By consolidating the production process, manufacturers can often reduce overhead costs and pass those savings on to you. Additionally, with a turnkey partner, you might benefit from bulk purchasing of components, further lowering costs.

Reduced Time to MarketTime is of the essence in the fast-paced appliance market. A turnkey manufacturer can significantly reduce the time it takes to bring a product to market. From initial design to final production, their streamlined process ensures that your air fryer can hit the shelves quickly, capitalizing on market trends and consumer demand.

Ongoing Support and MaintenanceA reputable turnkey manufacturer typically offers ongoing support and maintenance services. This includes technical assistance, troubleshooting, and parts replacement, which can be invaluable in maintaining customer satisfaction and brand reputation.

Innovation and Continuous ImprovementTurnkey manufacturers are often at the forefront of technological advancements. They invest in research and development to stay ahead of the curve, which means you can expect your air fryer to incorporate the latest innovations and features. This not only keeps your product fresh and appealing but also positions your brand as a leader in the industry.

Brand Reputation and TrustBy partnering with a manufacturer that holds a UL certification, you’re aligning your brand with a symbol of trust and quality. Consumers are more likely to purchase products that have undergone rigorous safety testing and certification, which can bolster your brand reputation and customer loyalty.

Market Expansion OpportunitiesA turnkey UL certified air fryer manufacturer can help you expand into new markets. Their expertise in navigating international regulations and standards ensures that your product can comply with the requirements of different regions, making it easier to enter new markets and grow your business globally.

Long-Term Strategic PartnershipsWhen you partner with a turnkey manufacturer, you’re not just outsourcing production; you’re establishing a long-term strategic relationship. This partnership can lead to collaborative product development, shared market insights, and a mutual commitment to your brand’s success.

In conclusion, the benefits of partnering with a turnkey UL certified air fryer manufacturer are multifaceted. From streamlined production and quality assurance to customization and cost savings, these partnerships can provide a solid foundation for your brand’s growth and success in the competitive kitchen appliances market.

In the ever-evolving landscape of kitchen appliances, embracing the future means understanding the transformative power of technology. The integration of smart features, energy efficiency, and innovative designs is reshaping how we interact with our kitchens. As consumers, we are not just looking for appliances that perform tasks; we are seeking companions that enhance our daily lives. This conclusion reflects on the importance of staying ahead in the kitchen appliance market and the role that manufacturers, like those offering turnkey UL certified air fryer solutions, play in shaping this future.

The kitchen, once a place for cooking, has now become a hub for health, entertainment, and socialization. As such, appliances that cater to these multifaceted needs are becoming increasingly popular. For instance, the air fryer, once a niche product, has surged in popularity due to its ability to offer healthier cooking options without compromising on taste or convenience. This shift in consumer preferences is driving manufacturers to think outside the box, pushing the boundaries of what’s possible in kitchen appliance design.

Manufacturers that offer turnkey solutions for air fryers are not just providing a product; they are offering a complete package that includes design, manufacturing, certification, and distribution. This holistic approach ensures that the final product is not just functional but also safe, reliable, and appealing to the modern consumer. The UL certification, in particular, stands as a testament to the manufacturer’s commitment to quality and safety, which is paramount in the kitchen appliance industry.

Partnerships with turnkey manufacturers can be a game-changer for brands looking to enter or expand in the air fryer market. By outsourcing the complexities of production and certification, these brands can focus on their core competencies—marketing, sales, and customer service. This strategic collaboration allows for a more agile and responsive approach to market demands, as manufacturers can quickly adapt to new trends and consumer needs.

One notable aspect of turnkey solutions is the flexibility they offer in terms of customization. Brands can work closely with manufacturers to tailor the design and features of the air fryer to match their brand identity and target market. This level of customization not only helps in differentiation but also in creating a unique selling proposition that resonates with consumers. Whether it’s a sleek, modern design or a feature-rich model with advanced technology, the possibilities are vast.

Case studies of successful air fryer OEM projects demonstrate the tangible benefits of such partnerships. For instance, a well-known brand that partnered with a turnkey manufacturer to produce a line of air fryers saw a significant increase in market share. The turnkey manufacturer’s expertise in design, production, and certification allowed the brand to bring their product to market faster and with greater efficiency. This success story is just one example of how turnkey solutions can propel a brand to new heights.

Another key advantage of working with a turnkey UL certified air fryer manufacturer is the assurance of compliance with global standards. This is particularly crucial in the kitchen appliance industry, where safety and regulatory compliance are non-negotiable. By partnering with a manufacturer that has a proven track record of meeting stringent certification requirements, brands can rest assured that their products will meet or exceed international safety standards. This peace of mind allows brands to focus on growing their business, rather than worrying about the technicalities of certification.

The future of kitchen appliances is bright, and it is being illuminated by innovations that make cooking more enjoyable, healthier, and efficient. Smart appliances that can connect to our smartphones or even control themselves based on recipes are becoming the norm. Manufacturers that can provide turnkey solutions for these cutting-edge products are at the forefront of this revolution.

In conclusion, the future of kitchen appliances is about blending functionality with technology, and turnkey manufacturers are instrumental in making this vision a reality. By offering comprehensive services that cover design, production, certification, and distribution, these manufacturers are not just suppliers; they are partners in the journey towards a smarter, more connected kitchen. As consumers demand more from their appliances, the role of turnkey solutions in OEM production will only continue to grow, ensuring that the kitchen of the future is as innovative as it is indispensable.