Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

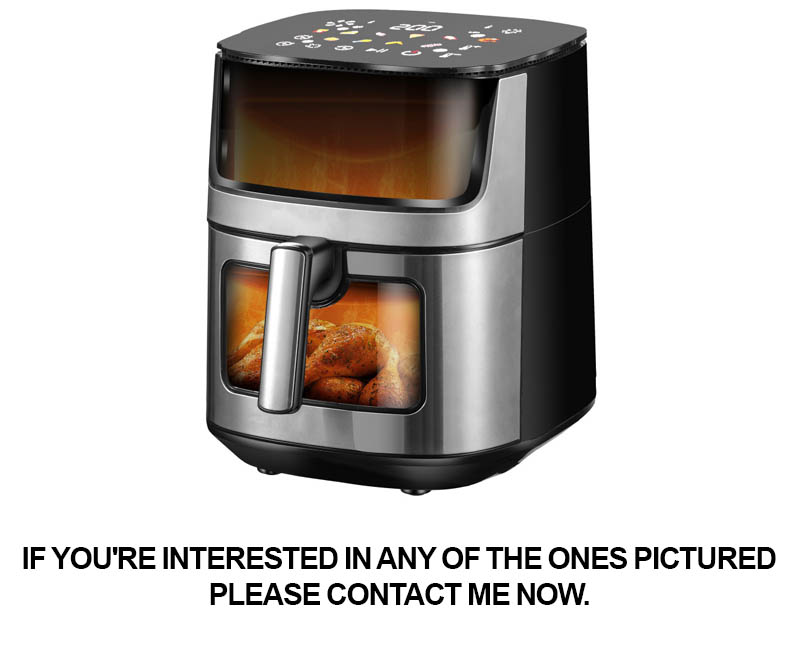

In a world where culinary innovation meets efficiency, the evolution of industrial waffle makers has become a game-changer for busy cafes, hotels, and event venues. As these appliances become more sophisticated, understanding their role in the commercial kitchen landscape is crucial. Let’s delve into the transformative journey of waffle making and the future it holds.

The kitchen appliance industry has seen a fascinating transformation over the years, and one area that has particularly caught fire is the rise of industrial waffle makers. These robust, high-powered machines have transitioned from mere kitchen gadgets to essential tools for commercial kitchens. Let’s delve into the reasons behind this surge in popularity.

Firstly, the demand for consistency and efficiency in commercial settings has never been higher. In the bustling world of cafes, restaurants, and hotels, the ability to churn out waffles in a timely manner is crucial. Industrial waffle makers, with their robust construction and reliable performance, have stepped in to meet this demand, offering a level of precision and speed that residential models simply can’t match.

As the foodservice industry continues to evolve, operators are looking for solutions that not only save time but also maintain the quality of their products. These industrial machines are designed to produce waffles in batches, ensuring a steady supply that can keep up with high customer turnover. Their durability is unmatched, with heavy-duty components that can withstand the rigors of continuous use, making them a favorite among busy chefs.

Another factor fueling the growth of industrial waffle makers is the increasing popularity of waffles themselves. From classic Belgian waffles to whimsical shapes and flavors, waffles have become a staple on many menus. This culinary versatility has opened the door for a wide range of waffle makers, each tailored to specific recipes and textures. The ability to customize the waffle-making experience has given rise to specialized industrial models that cater to diverse tastes and dietary preferences.

The technology behind these machines has also advanced significantly. Modern industrial waffle makers often come with features like adjustable temperature controls, allowing operators to achieve the perfect level of crispiness for their waffles. Some models even include timers and automatic shut-offs, ensuring safety and reducing the risk of overcooking. These technological enhancements have not only improved the quality of the final product but have also made the process more user-friendly for kitchen staff.

Moreover, the market for industrial waffle makers has expanded due to the rise of pop-up markets and food trucks. These mobile vendors need reliable equipment that can withstand travel and be easily set up. Industrial waffle makers fit this need perfectly, providing a portable solution that doesn’t compromise on quality or performance.

As sustainability becomes a growing concern, the industry has also seen a shift towards energy-efficient appliances. Many industrial waffle makers are now designed with energy-saving features in mind, reducing operational costs and minimizing their environmental footprint. This green approach has resonated with both businesses and consumers, further driving the demand for these waffle makers.

Furthermore, the global foodservice market is expanding, with new markets and emerging trends shaping consumer preferences. International operators are increasingly incorporating waffles into their menus, leading to a global demand for reliable waffle-making solutions. This cross-cultural appeal has contributed to the widespread adoption of industrial waffle makers across various countries.

Lastly, the cost-effectiveness of these machines cannot be overlooked. Despite their high-quality construction and advanced features, industrial waffle makers offer excellent value for money. They are a one-time investment that can provide years of service, making them a smart choice for any commercial kitchen looking to maximize its budget.

In conclusion, the rise of industrial waffle makers in the kitchen appliance industry is a testament to the evolving needs of the foodservice sector. These machines have become a cornerstone of commercial kitchens, offering a combination of efficiency, versatility, and technological innovation that has captured the hearts and minds of chefs and operators worldwide. With the continued growth of the foodservice industry, it’s clear that the industrial waffle maker’s journey is far from over, and it’s poised to play an even more significant role in the years to come.

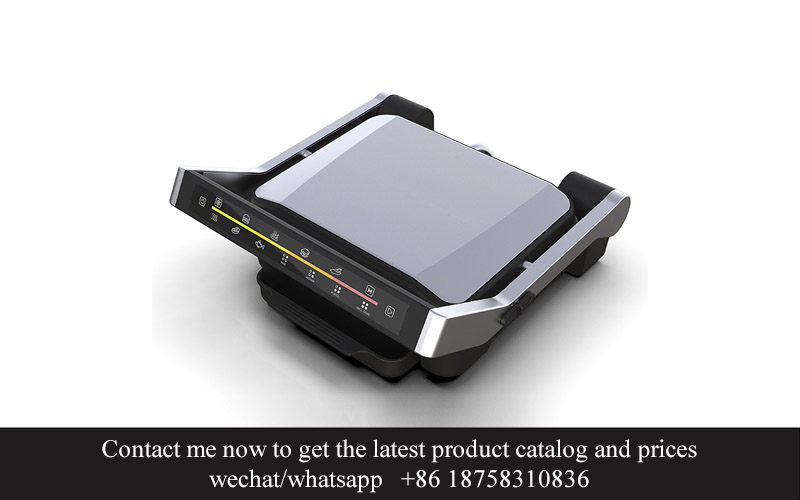

In the bustling world of commercial kitchens, where efficiency and reliability are paramount, the adoption of 220V industrial waffle makers has surged. This voltage standard has become the go-to choice for several compelling reasons that cater to the unique demands of professional cooking environments.

The robust power delivery that 220V provides is a game-changer for commercial kitchens. These waffle makers are designed to handle the high volume of production required in a restaurant setting, ensuring that waffles are produced quickly and consistently. The higher voltage translates to a more powerful heating element, which can distribute heat evenly across the waffle iron, resulting in a perfectly golden and crispy texture every time.

Energy efficiency is another key factor. While it might seem counterintuitive, 220V appliances often consume less energy than their lower-voltage counterparts. This is because they can perform the same task with less energy due to their higher power output. For businesses that operate around the clock, this can lead to significant savings on their electricity bills over time.

The size and build quality of 220V industrial waffle makers are also noteworthy. These machines are typically larger and more durable than residential models, which is essential in a commercial setting where they are subjected to constant use. The robust construction ensures that the waffle makers can withstand the rigors of a busy kitchen, with components that are less likely to fail or overheat.

Safety is a top priority in commercial kitchens, and 220V waffle makers often come with built-in safety features that are designed to prevent accidents. These can include automatic shut-off mechanisms that activate if the machine overheats or if it is left unattended for an extended period. The higher voltage also means that the heating elements can be designed to be more compact, reducing the risk of burns or electrical hazards.

Another advantage of 220V waffle makers is the consistency they offer. The stable power supply ensures that the temperature remains constant, which is crucial for producing waffles with a uniform texture and color. This reliability is particularly important for businesses that rely on their waffles as a signature dish, as customers have come to expect a certain level of quality and consistency.

In terms of maintenance, 220V industrial waffle makers are designed to be easy to clean and maintain. The non-stick surfaces and removable parts make it simpler to clean the iron after each use, reducing the risk of food particles burning onto the surface and causing odors or flavors to transfer to the next batch of waffles.

The versatility of 220V waffle makers is also a significant draw for commercial users. Many models are capable of making different shapes and sizes of waffles, from classic Belgian to fun and quirky designs. This allows businesses to cater to a wide range of tastes and preferences, from the traditionalist to the adventurous foodie.

Lastly, the global standardization of 220V in many countries means that these waffle makers are widely available and compatible with commercial kitchens worldwide. This simplifies the procurement process and ensures that businesses can source reliable equipment without the need for costly conversions or adapters.

In conclusion, the rise of 220V industrial waffle makers in the kitchen appliance industry is a testament to the evolving needs of commercial kitchens. With their powerful performance, energy efficiency, safety features, and versatility, these machines are becoming the preferred choice for businesses looking to elevate their waffle game.

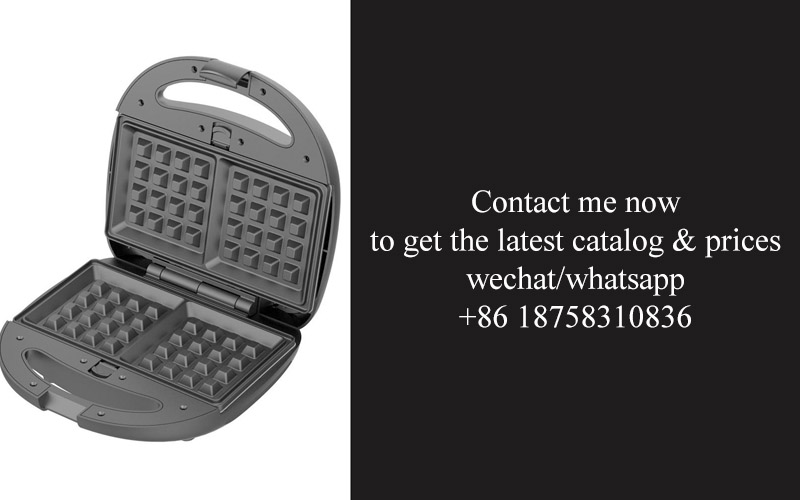

In recent years, the industrial waffle maker market has seen a surge in innovative designs and functionalities that cater to both aesthetic appeal and efficiency. These advancements are reshaping the way we think about waffle production in commercial settings.

The integration of smart technology has been a game-changer. Many modern industrial waffle makers now come with digital interfaces, allowing for precise temperature control and timer settings. This ensures consistency in the waffle’s texture and cooking time, a crucial factor in high-volume operations.

Moreover, the design of these machines has evolved to accommodate different types of batter. Some models are now equipped with adjustable plates that can handle both thick Belgian-style waffles and thin American-style ones, offering versatility to operators. The non-stick surfaces are also improved, reducing the need for butter or oil and ensuring that the waffles release effortlessly.

Safety features have become a priority in the design of these appliances. Industrial waffle makers now often include features like automatic shut-off to prevent overheating and burns. Childproof locks and durable, heat-resistant handles are also common, ensuring a safer working environment.

In terms of functionality, there’s a noticeable shift towards energy efficiency. Newer models are designed to consume less power without compromising on output, which is not only cost-effective for businesses but also environmentally friendly. The inclusion of eco-friendly materials and energy-saving modes has made these waffle makers more appealing to eco-conscious operators.

The inclusion of programmable settings is another innovation. Some waffle makers now offer customizable cooking times and temperatures, allowing operators to cater to specific customer preferences. This feature is particularly valuable in the catering industry, where different groups may have varying dietary requirements.

Cleaning has also seen improvements. Modern industrial waffle makers come with removable and dishwasher-safe parts, making the post-cooking cleanup process much quicker and less labor-intensive. The sleeker designs also contribute to easier cleaning, with fewer crevices where food particles can get trapped.

The trend towards portability is another interesting development. Some models are designed to be compact and lightweight, making them suitable for mobile vendors and pop-up food stalls. These portable waffle makers can be easily transported and set up at various locations, providing a unique and interactive element to foodservice operations.

Additionally, there’s a growing emphasis on customization and personalization. Some industrial waffle makers now come with interchangeable molds or decorative patterns on the waffle plates, allowing for a wide range of creative designs. This feature is particularly popular in theme parks and special events, where unique waffles can become a memorable part of the experience.

Lastly, the integration of IoT (Internet of Things) capabilities is beginning to emerge. Imagine being able to monitor and control your waffle maker remotely, adjusting settings based on real-time data. While still in its early stages, this innovation has the potential to revolutionize the way commercial kitchens operate, providing greater convenience and efficiency.

The continuous evolution in design and functionality of industrial waffle makers reflects the industry’s commitment to meeting the demands of a diverse and sophisticated market. From smart technology and safety features to energy efficiency and customization, these advancements are setting new standards for what a commercial waffle maker can be.

In the ever-evolving landscape of the kitchen appliance industry, staying ahead of the curve is crucial. The latest market trends are not just driven by consumer preferences but are also shaped by technological advancements and shifting economic landscapes. Here are some key insights gleaned from data-driven analysis:

The integration of smart technology is becoming more prevalent, with appliances that can be controlled remotely via smartphones or tablets. This not only offers convenience but also provides businesses with the ability to monitor and manage their equipment more efficiently.

Energy efficiency is a major focus, with a growing number of industrial waffle makers now featuring eco-friendly designs that reduce energy consumption. This shift is not only beneficial for the environment but also for the bottom line, as businesses seek to cut operational costs.

Customization is on the rise, with manufacturers offering a variety of models that cater to specific needs. From waffle shapes and sizes to adjustable temperature controls, these appliances are designed to meet the diverse demands of different markets, from cafes to catering services.

Sustainability is a buzzword that’s not just about the materials used in the appliances but also about the lifecycle of the product. Companies are increasingly looking for ways to minimize waste and ensure that their products can be easily recycled or repurposed at the end of their life.

Health and safety regulations are also influencing the market, with an emphasis on compliance. Waffle makers that come with safety features like automatic shut-offs and non-slip bases are becoming standard, ensuring that both users and consumers are protected.

The rise of health-conscious consumers has led to a demand for healthier waffle options. This has spurred innovation in the form of gluten-free, low-fat, and organic ingredients that can be used with these appliances, appealing to a broader audience.

Data analytics is playing a pivotal role in understanding market trends. By analyzing sales data, consumer feedback, and social media sentiment, manufacturers can identify emerging trends and adapt their product lines accordingly.

E-commerce has transformed the way products are sold, with a significant portion of sales now occurring online. This shift has necessitated a focus on digital marketing and online customer service, ensuring that businesses can reach their target audience more effectively.

The importance of brand identity and storytelling cannot be overstated. Consumers are not just looking for a product; they are seeking a brand that resonates with their values. This has led to a surge in creative branding strategies that tell the story of the product’s origin, its impact on the community, and its role in the broader culinary landscape.

Lastly, the global nature of the market has introduced new challenges and opportunities. With the ability to reach customers across the globe, manufacturers must navigate cultural differences and comply with international regulations, all while maintaining a consistent brand experience.

These insights, derived from a combination of sales figures, consumer surveys, and industry reports, paint a clear picture of where the kitchen appliance industry, particularly in the realm of industrial waffle makers, is heading. By staying informed and adapting to these trends, businesses can ensure they remain competitive and innovative in the years to come.

In the fast-paced world of hospitality, efficiency and consistency are key. Industrial waffle makers have become the perfect match for busy cafes, hotels, and event venues for several compelling reasons. Here’s how they fit seamlessly into the hustle and bustle of these industries:

Cafes, with their diverse menus and constant flow of customers, need reliable appliances that can keep up with demand. Industrial waffle makers are designed to churn out waffles at a rapid pace, ensuring that no customer is left waiting. Their sturdy construction and large, continuous feed systems allow for a steady stream of waffles, perfect for breakfast buffets, lunchtime snacks, or late-night treats.

Hotels, especially those with multiple dining outlets, face the challenge of providing a variety of options to their guests while maintaining high-quality service. Industrial waffle makers are a game-changer in this scenario. They can be easily integrated into hotel breakfast stations, room service setups, or even as a feature in executive lounges, offering a delightful touch to the hotel experience.

Event venues, from wedding halls to conference centers, require equipment that can handle the unpredictable nature of large gatherings. Whether it’s a birthday party, a corporate event, or a music festival, industrial waffle makers are up to the task. Their ability to produce a large number of waffles in a short amount of time ensures that there’s always a supply for guests, no matter the scale of the event.

The compact size of many industrial waffle makers makes them an ideal choice for spaces where every inch counts. They can be tucked away in a corner of a busy kitchen without taking up valuable counter space. This not only maximizes efficiency but also keeps the kitchen looking tidy and organized.

In terms of functionality, these waffle makers are a cut above the rest. Features like adjustable temperature controls allow chefs to achieve the perfect waffle texture every time, from a crispy golden exterior to a soft, fluffy interior. Some models even come with non-stick surfaces, reducing the need for butter or oil and making cleanup a breeze.

Moreover, the durability of industrial waffle makers is unmatched. They are built to withstand the rigors of commercial use, with materials that can endure high temperatures and frequent cleaning. This longevity means that they can be a long-term investment for businesses, reducing the need for frequent replacements.

Safety is also a top priority in these waffle makers. With features like automatic shut-off and temperature regulation, the risk of accidents is minimized. This is crucial in environments where hot appliances are used around children or in areas with a high turnover of staff.

The versatility of industrial waffle makers is another reason they are a perfect fit for busy establishments. They can be used to create traditional Belgian waffles or innovative flavors and shapes, keeping the menu fresh and exciting. From sweet to savory, the possibilities are endless, catering to a wide range of palates.

From a cost perspective, these waffle makers are efficient. They use less energy compared to traditional home models, which can lead to significant savings over time. Additionally, their ability to produce a large quantity of waffles at once means that the cost per waffle is lower, contributing to the profitability of the business.

In the realm of sustainability, industrial waffle makers are also making waves. With an increasing focus on eco-friendly practices, these appliances are designed with energy efficiency in mind. They contribute to a greener operation, which is becoming a crucial factor for customers who are conscious of their environmental footprint.

In conclusion, the rise of industrial waffle makers in the kitchen appliance industry is a testament to their ability to meet the needs of busy cafes, hotels, and event venues. With their efficiency, durability, safety, versatility, and cost-effectiveness, these appliances are not just a tool but a partner in delivering exceptional service and unforgettable experiences.

In the bustling world of commercial kitchens, selecting the right industrial waffle maker can be a game-changer. Here are some key tips to help you make the perfect choice:

Consider the Size of Your EstablishmentThe size of your cafe, hotel, or event venue plays a crucial role in determining the size of the waffle maker you need. Larger models can accommodate more patrons at once, making them ideal for high-traffic areas. Conversely, if your space is limited, opting for a compact or countertop model might be more suitable.

Evaluate the Capacity and SpeedA waffle maker with a higher capacity can handle a larger number of orders simultaneously, which is essential during peak hours. Additionally, consider the speed at which the machine can produce waffles. Quick-cook models can significantly reduce wait times and keep your customers satisfied.

Look for Easy Maintenance FeaturesIn a busy kitchen, time is of the essence. A waffle maker that boasts easy-to-clean surfaces and components can save you valuable minutes each day. Non-stick coatings and removable plates make for quick and efficient cleaning, ensuring your equipment stays in top condition.

Consider the Power SourceWhile 220V is the standard for industrial use, some waffle makers come with alternative power options, such as 110V or even solar-powered models. Assess your power availability and energy efficiency goals to determine the most suitable power source for your operation.

Don’t Ignore the Build QualityIndustrial waffle makers are built to withstand the rigors of commercial use. Look for sturdy construction, durable materials, and robust components. A machine that can withstand frequent use and still look and function like new is worth the investment.

Check for Customization OptionsDepending on your menu, you may need a waffle maker that can accommodate various shapes and sizes. Some models offer adjustable settings for browning levels and thickness, allowing you to cater to a diverse range of preferences. Additionally, some machines come with interchangeable plates for different waffle designs.

Consider User-Friendly ControlsIn a fast-paced kitchen, intuitive controls are essential. Look for waffle makers with simple, easy-to-use interfaces that require minimal training for your staff. Some models even feature programmable settings that can be pre-set to your preferred browning level, ensuring consistency every time.

Safety Features are a MustWhen dealing with hot equipment and ingredients, safety should always be a top priority. Ensure your waffle maker has safety features such as automatic shut-off, cool-touch handles, and non-slip bases to prevent accidents and protect both your staff and customers.

Research Warranty and Customer SupportA good warranty and reliable customer support can make a significant difference when dealing with an industrial appliance. Look for brands that offer comprehensive warranties and responsive customer service to address any issues that may arise during your waffle maker’s lifespan.

Read Reviews and Seek RecommendationsBefore making your final decision, take the time to read reviews from other commercial kitchen owners and staff. Their firsthand experiences can provide valuable insights into the performance, reliability, and durability of different waffle maker models.

By considering these factors, you can ensure that the industrial waffle maker you choose will not only meet the demands of your busy establishment but also enhance the overall quality of your menu and customer satisfaction.

The evolution of technology in the culinary world has brought about a remarkable transformation in the way we approach cooking. Waffle making, once a simple weekend activity, has now become a staple in commercial kitchens. The future of waffle making promises a blend of innovation, sustainability, and convenience. Here’s a glimpse into what we can expect in the coming years:

Advancements in Material ScienceMaterials used in industrial waffle makers are becoming more advanced. We’re seeing a shift towards eco-friendly and durable materials that not only enhance the longevity of the appliance but also reduce waste. Expect to see more appliances made from recycled metals and sustainable plastics that are both safe and efficient.

Smart Technology IntegrationAs the Internet of Things (IoT) continues to permeate various industries, kitchen appliances are not far behind. The future waffle makers may come equipped with smart features that allow for remote control, predictive maintenance, and even personalized settings based on user preferences. Imagine being able to order a freshly baked waffle from your phone, regardless of where you are.

Customization and PersonalizationThe demand for individualized food experiences is on the rise, and waffle makers are no exception. Future models could offer a variety of patterns, textures, and even color options for waffles. With the ability to program specific settings for each customer’s taste, the possibilities are virtually endless.

Health and WellnessWith health consciousness becoming increasingly important, the future of waffle making will likely see a focus on healthier ingredients and lower-fat options. We might see the development of healthier oils, non-stick coatings that are free from harmful chemicals, and even waffle makers that can bake healthier variations of traditional waffles.

Sustainability and Energy EfficiencyAs environmental concerns grow, so does the need for sustainable practices. Future waffle makers could incorporate energy-saving technologies, such as induction heating, which not only reduces energy consumption but also provides a more precise temperature control. The industry might also see the introduction of appliances that are designed for recycling or that use renewable energy sources.

Interactive and Educational FeaturesIn the age of information, educational features could become a part of the waffle-making experience. Imagine a waffle maker that not only bakes but also provides nutritional information, recipes, and interactive cooking tips. This could be especially appealing to culinary schools and educational institutions.

Global Trends and Cultural FusionThe world is becoming more interconnected, and this is reflected in the culinary arts. Waffle makers of the future may feature designs and functionalities inspired by various cultures, offering a range of international waffle styles. From Belgian Liege to American pancake waffles, the variety could be vast, catering to a global audience.

Community and Social SharingAs social media continues to influence consumer behavior, waffle makers may become more than just cooking appliances; they could become social hubs. Future models might be designed to encourage sharing and community engagement, perhaps with built-in features for live streaming cooking sessions or social media integration.

Accessibility and InclusivityTechnology has a way of making products more accessible to everyone. The future of waffle making may see the development of appliances that cater to individuals with disabilities, offering ergonomic designs and assistive technologies. Inclusivity will be a key focus, ensuring that everyone can enjoy the joy of making waffles.

The rise of the industrial waffle maker has been meteoric, and the future holds even more exciting possibilities. From cutting-edge materials to smart technology and health-conscious innovations, the journey of waffle making is set to continue evolving, bringing new experiences and tastes to the world.

In recent years, the evolution of industrial waffle makers has transformed the art of waffle making into a precision craft. These appliances are not just kitchen tools but have become integral to the success of busy cafes, hotels, and event venues. They’ve embraced innovation and functionality, turning out perfectly crafted waffles with ease and efficiency. The future of waffle making is bright, and here’s a glimpse into what we can expect in the coming years. From smart technology integration to sustainable materials, the landscape of waffle making is about to change. Let’s delve into the myriad of advancements and what they mean for both professionals and enthusiasts alike.

As we look ahead, one of the most significant shifts we can anticipate is the increased focus on energy efficiency. With the growing awareness of climate change and the push for green initiatives, industrial waffle makers are set to become more energy-conscious. This could mean advancements in insulation and heating elements that reduce energy consumption without compromising on the quality of the waffles.

Another area where we’re likely to see innovation is in the design of these appliances. Compact and sleek models are already becoming popular, but the future may bring us even more space-saving solutions. Think of waffle makers that can be mounted on walls or integrated into kitchen counters in a way that maximizes space without sacrificing ease of use.

Smart technology is poised to make a significant impact. Imagine a waffle maker that can be controlled remotely, allowing chefs to monitor and adjust the cooking process from their phones or tablets. This could be particularly beneficial for large-scale operations where consistency is key, or for those who want to ensure their waffles are perfectly golden and crispy even when they’re not at the kitchen station.

Customization is another trend that’s gaining traction. As consumers become more health-conscious and interested in unique flavors, industrial waffle makers may start offering a variety of attachments and inserts that allow for different shapes, textures, and even the ability to create waffles with ingredients that cater to specific dietary preferences, such as gluten-free or vegan options.

Durability and maintenance are also crucial factors that will continue to evolve. The future may see waffle makers made with longer-lasting materials and components that are easier to clean and maintain. This not only extends the life of the appliance but also reduces the cost of ownership over time.

In terms of health and safety, advancements in safety features are a must. We can expect to see waffle makers with improved heating elements that reduce the risk of burns and spills, as well as anti-slip bases and handles that provide a secure grip even when the appliance is hot.

The integration of IoT (Internet of Things) technology is another exciting possibility. Imagine a waffle maker that can send real-time data to kitchen management systems, providing insights into usage patterns and maintenance schedules. This level of connectivity could help streamline operations and reduce downtime.

Lastly, sustainability is becoming a driving force in many industries, and waffle making is no exception. We may see a rise in the use of eco-friendly materials and manufacturing processes that minimize waste and reduce the carbon footprint of these appliances.

In conclusion, the future of waffle making with industrial appliances is filled with possibilities. It’s an exciting time for both professionals and consumers who love waffles, as new innovations continue to push the boundaries of what’s possible in the kitchen. From energy efficiency to smart technology, durability to sustainability, the art of waffle making is set to become even more sophisticated and accessible in the years to come.