Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the realm of modern living, the kitchen has transcended its traditional role as a mere space for cooking. It has evolved into a hub of innovation and technological integration, where every appliance plays a pivotal role in enhancing our daily lives. At the heart of this transformation lies the integrated circuit board (ICB), a tiny yet mighty component that has silently powered the leap in kitchen appliance technology. As we delve into the intricate world of ICBs and their impact on the European and American markets, it becomes clear that the future of cooking is not just about convenience; it’s about revolutionizing the way we interact with our kitchen gadgets.

The kitchen, once a mere utilitarian space for cooking, has transformed into a hub of innovation and comfort. The evolution of kitchen appliances mirrors this transformation, with each era bringing forth new inventions that have not only simplified daily tasks but also elevated the culinary experience. From the early days of manual labor to the sophisticated smart kitchens of today, the journey has been marked by remarkable progress.

In the beginning, kitchen appliances were scarce and primarily manual. The spinning jenny, a precursor to the washing machine, was introduced in the early 18th century, revolutionizing the laundry process. Similarly, the ice box, which eventually evolved into the refrigerator, came into existence in the 19th century, extending the shelf life of food and changing the way families managed their groceries.

The 20th century saw a surge in kitchen appliance innovation. The electric mixer, blender, and food processor were introduced, streamlining cooking and baking. The refrigerator became more efficient and compact, fitting seamlessly into kitchen designs. The introduction of the microwave oven in the 1960s was another game-changer, allowing for quick and easy cooking without the need for stovetop heat.

As technology advanced, so did the complexity of kitchen appliances. The 1970s and 1980s saw the rise of programmable appliances, such as the modern oven and the dishwasher, which could be set to run at specific times and temperatures. The integration of timers and sensors further enhanced convenience and efficiency.

The 1990s brought about a new wave of innovation with the advent of computerized appliances. These included dishwashers that could optimize the cleaning cycle based on soil levels and refrigerators with digital temperature controls. The integration of digital displays and user interfaces made appliances more user-friendly and accessible.

The 21st century has been a period of exponential growth in kitchen appliance technology. Smart appliances, equipped with integrated circuit boards (ICBs), have become the norm. These smart devices can connect to the internet, allowing users to control them remotely via smartphones or tablets. Smart refrigerators can track inventory, remind users to purchase groceries, and even suggest recipes based on the contents of the fridge.

Ovens have evolved to include convection capabilities, ensuring even heat distribution for better cooking results. Induction cooktops, which use electromagnetic fields to heat pots and pans directly, have replaced traditional electric and gas burners, offering greater energy efficiency and precision. The rise of sous-vide cooking, facilitated by precise temperature control appliances, has opened up new culinary possibilities.

The evolution of kitchen appliances has not only focused on functionality but also on design. Modern appliances are sleeker, more stylish, and often designed to be a centerpiece in the kitchen rather than an afterthought. Materials such as stainless steel, glass, and ceramic have become popular for their durability and aesthetic appeal.

In addition to the physical changes, there has been a shift in consumer expectations. Today’s consumers demand appliances that are not only efficient and convenient but also sustainable. Energy-efficient models are becoming the standard, with manufacturers striving to reduce the environmental impact of their products.

The journey of kitchen appliance evolution has been a testament to human ingenuity and the relentless pursuit of convenience, efficiency, and innovation. As we continue to push the boundaries of technology, the kitchen of the future promises to be a place where cooking is both an art and a science, thanks to the relentless evolution of the appliances that call it home.

Integrated circuit boards (ICBs) have quietly become the unsung heroes of modern kitchen appliances. These intricate pieces of technology are the beating heart of countless devices, from the sleek stove to the smart refrigerator. Their significance in the kitchen appliance industry cannot be overstated, as they drive innovation, efficiency, and connectivity like never before.

ICBs are the foundation for the mini-computers that power today’s kitchen gadgets. They are responsible for processing complex algorithms that control the intricate workings of appliances. Whether it’s adjusting the temperature of an oven to the precise degree or managing the intricate cycles of a dishwasher, ICBs ensure that these tasks are performed with pinpoint accuracy.

One of the most notable aspects of ICBs is their role in energy efficiency. With the increasing emphasis on sustainability and eco-friendliness, ICBs have enabled appliances to consume less energy while still delivering top performance. This not only benefits the environment but also saves consumers money on their utility bills.

The integration of ICBs has also paved the way for the rise of smart kitchen appliances. These devices can communicate with each other and with users, providing a seamless and interconnected kitchen experience. From timers that sync with your smartphone to fridges that can order groceries automatically, ICBs have transformed the kitchen into a smart, intuitive space.

Moreover, ICBs have made appliances more user-friendly. With the help of graphical user interfaces (GUIs) and touchscreens, users can navigate settings and functions with ease. This has democratized the kitchen, allowing even those without a technical background to enjoy the benefits of high-tech appliances.

In terms of safety, ICBs have been instrumental in enhancing the security of kitchen appliances. With advanced diagnostic capabilities, they can detect malfunctions early on and alert users to potential hazards. This proactive approach not only prevents accidents but also extends the lifespan of appliances.

The miniaturization of ICBs has also led to a surge in portable kitchen gadgets. From handheld mixers to compact blenders, these devices are not only powerful but also incredibly convenient. ICBs have enabled these small appliances to pack a punch in a small package, making them perfect for on-the-go lifestyles and small living spaces.

The customization of appliances has also been made possible by ICBs. Users can now tailor their kitchen devices to their specific needs and preferences. From programmable ovens to customizable settings on a coffee machine, ICBs have given consumers the power to create a kitchen that suits their lifestyle.

Another critical role of ICBs is in the realm of connectivity. These tiny circuit boards enable appliances to connect to the internet, allowing for remote monitoring and control. This is particularly beneficial for people who are away from home but still want to ensure their kitchen is running smoothly.

In the world of food preparation, ICBs have revolutionized the way we cook. Induction cooktops, for instance, use ICBs to sense the presence of pots and pans, adjusting the heat output to the optimal level. This not only saves energy but also ensures that food is cooked to perfection.

The medical applications of ICBs in kitchen appliances are also worth mentioning. For example, smart scales that can track your weight and body composition, or even fridges that can alert you to expired food items, are all powered by ICBs. These features not only improve health and wellness but also contribute to a more organized kitchen.

Lastly, ICBs have become a key factor in the competitive landscape of the kitchen appliance industry. Companies that can develop and integrate advanced ICB technologies into their products gain a significant edge over their competitors. This has led to a race to innovate, pushing the boundaries of what is possible in the kitchen.

In conclusion, the significance of ICBs in the kitchen appliance industry cannot be overstated. They are the driving force behind the technological advancements that have transformed the way we interact with our kitchen devices. From enhancing efficiency and safety to enabling connectivity and personalization, ICBs have become an indispensable component in the modern kitchen.

In the realms of kitchen appliances, the European and American markets stand as testaments to the evolving landscape of technology and consumer preferences. Europe, known for its rich culinary heritage and sophisticated taste, has become a hub for premium and energy-efficient appliances. Conversely, the United States boasts a diverse market that reflects the fast-paced lifestyle and innovation-driven consumer base. Let’s delve into the dynamics shaping these markets.

Europe’s market is characterized by a strong focus on sustainability and design. Consumers here value not just the functionality of appliances but also their aesthetic appeal and environmental impact. The trend towards smart kitchen solutions has been prevalent, with integrated circuits (ICBs) playing a crucial role in creating interconnected devices. Brands like Miele, Bosch, and Siemens have set the standard, offering a range of ICB-powered appliances that cater to both eco-conscious consumers and those seeking high-tech features.

The rise of smart kitchens in Europe is driven by factors such as the aging population, which requires appliances that can offer convenience and support in daily tasks, and the younger demographic that embraces technology for a seamless and interactive home experience. ICBs are enabling these smart kitchens by integrating functionalities like voice control, predictive maintenance, and energy-saving modes. Moreover, the demand for smart appliances that can connect to home automation systems is on the rise, reflecting a shift towards a more connected lifestyle.

In the United States, the kitchen appliance market is vast and diverse, reflecting the varied needs and tastes of its consumers. The market is segmented into different tiers, with a significant portion of the sales coming from the premium and luxury segments. Brands like KitchenAid, Viking, and Sub-Zero have captured the hearts of consumers who seek top-of-the-line performance and design.

American consumers are particularly interested in appliances that combine efficiency with modern convenience. ICBs are central to this trend, as they enable appliances to be more responsive, predictive, and adaptable to individual usage patterns. For example, refrigerators equipped with ICBs can analyze usage patterns to optimize cooling cycles, thereby saving energy and reducing waste.

The American market also sees a high demand for built-in appliances, which are seamlessly integrated into cabinetry. This integration is made possible by ICBs, which allow for compact and efficient components that fit within tight spaces. Additionally, the rise of smart home technology has created a market for appliances that can be controlled remotely via smartphones or tablets, offering users flexibility and convenience.

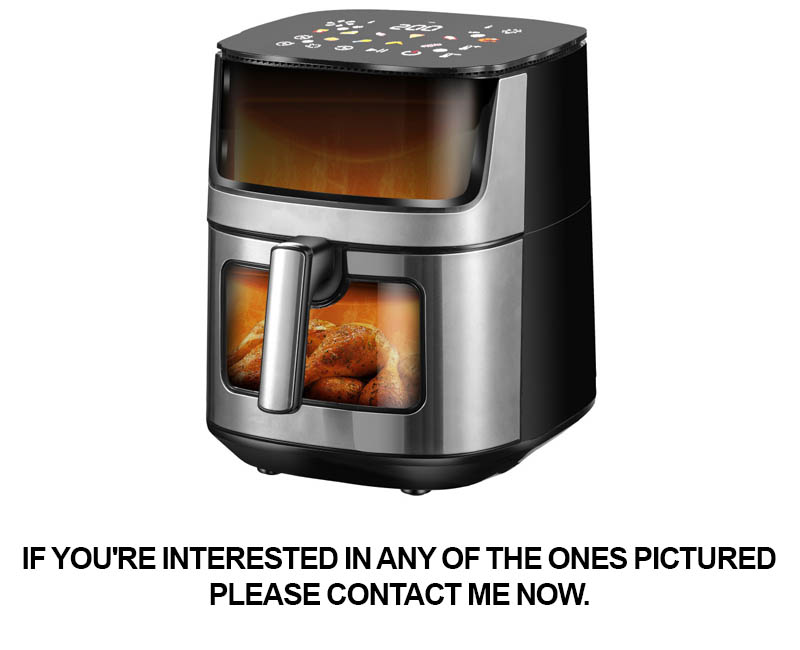

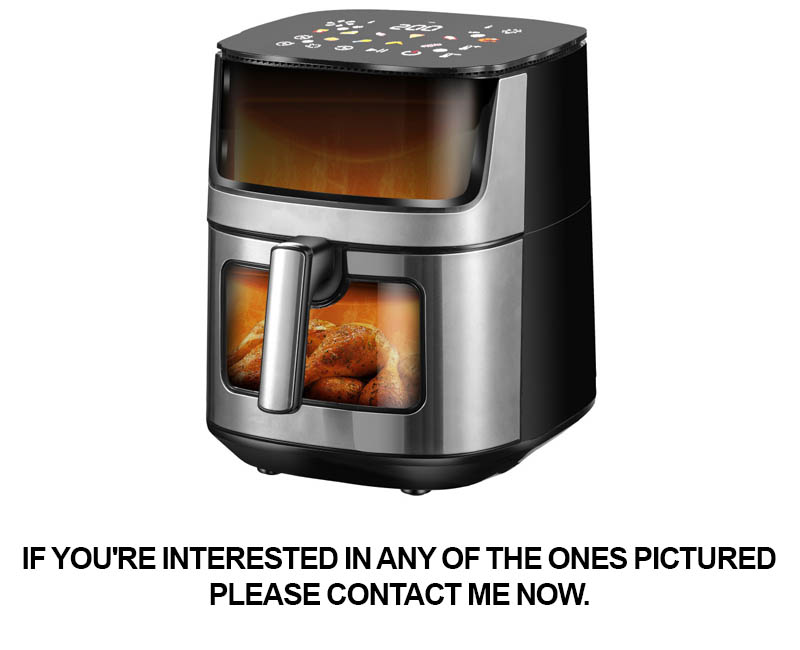

Both markets have witnessed the emergence of niche players that cater to specific consumer needs. For instance, the demand for small appliances designed for health and wellness, such as air fryers, sous-vide machines, and induction cooktops, has surged. ICBs are at the heart of these innovations, providing the intelligence to create appliances that not only perform well but also align with the consumer’s desire for health-conscious living.

On the regulatory front, both Europe and the U.S. have specific standards and certifications that appliances must meet. These standards are often a direct result of the technological advancements enabled by ICBs. In Europe, for example, the Energy Label Directive has influenced the design and energy consumption of appliances, pushing manufacturers to develop more efficient ICB-driven solutions. Similarly, in the U.S., the Energy Star program encourages the production of energy-efficient appliances that are also ICB-powered.

In conclusion, the European and American kitchen appliance markets are dynamic and interconnected by a common thread: the innovation enabled by integrated circuits. Whether it’s the emphasis on sustainability in Europe or the pursuit of luxury and convenience in the U.S., ICBs are central to the appliances that are shaping the modern kitchen. The future of these markets lies in continued technological advancements, which will further blur the lines between technology and culinary excellence.

The integration of Integrated Circuit Boards (ICBs) into kitchen appliances has opened up a world of possibilities, transforming the way we interact with our cooking environments. Here are some innovative ideas that are shaping the future of ICBs in the kitchen:

Smart Energy Management: Imagine a refrigerator that not only keeps your food fresh but also optimizes energy consumption based on your usage patterns. ICBs can enable real-time energy monitoring and adjustment, ensuring efficiency and cost savings.

Personalized Cooking Assistance: A kitchen appliance with an ICB can analyze your dietary needs and preferences, providing personalized cooking recommendations. For instance, a smart oven could suggest cooking times and temperatures for different types of meals, ensuring that each dish is perfectly prepared.

Seamless Connectivity: ICBs can facilitate seamless connectivity between various kitchen appliances, creating a cohesive ecosystem. You could start the coffee machine on your way to the kitchen, and it would be ready just as you step in, all thanks to the interconnectedness powered by ICBs.

Voice-Controlled Operations: With the rise of voice assistants, ICBs can enhance the user experience by enabling hands-free operation of kitchen appliances. Whether it’s adjusting the temperature on the stove or setting the timer on the microwave, voice commands can make cooking more intuitive.

Advanced Safety Features: ICBs can incorporate sophisticated safety protocols to prevent accidents in the kitchen. For example, a smart stove could detect when a pan is left unattended and automatically turn off the heat to prevent burns or fires.

Environmental Monitoring: Kitchen appliances equipped with ICBs can monitor environmental factors such as humidity and temperature, adjusting settings to maintain optimal conditions for food storage and preparation. This can extend the shelf life of your ingredients and reduce food waste.

Health and Nutrition Tracking: ICBs can be used to track the nutritional content of your meals, providing you with insights into your diet. A smart blender, for instance, could analyze the ingredients you’re using and suggest recipes that balance your macro and micronutrients.

Interactive Recipe Guides: ICBs can power interactive recipe guides that adapt to your taste and dietary restrictions. The appliance could display step-by-step instructions on a screen, highlighting key moments in the cooking process and suggesting substitutes if an ingredient is unavailable.

Customizable Cooking Styles: With ICBs, you can choose from a variety of cooking styles, from traditional to fusion, with a single appliance. The technology can mimic the heat distribution and cooking techniques of different cuisines, making your kitchen a culinary playground.

Predictive Maintenance: Kitchen appliances with ICBs can perform predictive maintenance, analyzing their performance to anticipate potential issues before they arise. This means less downtime and more reliability for your kitchen essentials.

Energy Harvesting: ICBs can be paired with energy-harvesting technologies to power kitchen appliances using ambient energy sources, such as solar or kinetic energy. This not only reduces the need for conventional power sources but also contributes to a greener kitchen environment.

These innovative ideas for ICBs in kitchen appliances represent just a fraction of the potential for this technology. As the industry continues to evolve, we can expect even more groundbreaking concepts that will redefine how we cook, live, and interact with our kitchen spaces.

The has witnessed a remarkable transformation over the years, with technological advancements playing a pivotal role. From the early days of simple appliances to the sophisticated, smart devices of today, the industry has evolved at a rapid pace. Let’s delve into some of the key trends and data analysis shaping the landscape of the industry.

Smart Integration is the New NormModern kitchen appliances are increasingly becoming smart and interconnected. Data from market research firms show a significant rise in the adoption of smart kitchen gadgets, with consumers gravitating towards devices that offer convenience and efficiency. Smart ovens, refrigerators, and dishwashers are not just cooking and storing food; they are also providing users with real-time data and predictive maintenance alerts.

Energy Efficiency and SustainabilityEnergy consumption has become a major concern, and the industry is responding with a focus on sustainability. Energy-efficient appliances are becoming more popular, driven by both consumer demand and regulatory requirements. Data indicates a growing market for appliances with energy-saving features, such as LED lighting, programmable settings, and smart controls that optimize energy use.

Customization and PersonalizationThe era of one-size-fits-all kitchen appliances is fading. Today’s consumers are looking for products that cater to their specific needs and preferences. Customizable appliances, such as ovens with multiple cooking modes or refrigerators with adjustable shelves, are gaining traction. The data reflects a shift towards personalization, with consumers willing to pay a premium for tailored solutions.

Health and Wellness FeaturesHealth consciousness is on the rise, and the industry is responding with appliances that promote wellness. Smart cookers that monitor nutritional content, air fryers that reduce oil usage, and water filters that improve water quality are becoming more common. Data shows a strong correlation between health-focused appliances and consumer interest, particularly among younger demographics.

Artificial Intelligence and Machine LearningAI and machine learning are beginning to make their mark in the industry. From voice-controlled appliances to predictive analytics that optimize cooking times, the integration of these technologies is expected to grow. Data suggests that AI-driven appliances could become a significant segment of the market within the next few years.

Connected Home EcosystemsThe concept of the connected home is expanding, and kitchen appliances are at the heart of this ecosystem. Smart devices that can be controlled remotely, share data with other home systems, and learn from user habits are becoming standard. The data indicates a surge in the number of households integrating multiple smart kitchen appliances, leading to a more cohesive and efficient living environment.

Regulatory Compliance and SafetyAs the industry evolves, regulatory compliance and safety standards remain a top priority. Data reveals a consistent focus on meeting international safety certifications and adhering to energy efficiency regulations. This trend is likely to continue, ensuring that consumers can trust the appliances they bring into their homes.

Globalization and Market ExpansionThe industry is becoming more globalized, with manufacturers looking to expand into new markets. Data points to emerging regions like Asia and South America as potential growth areas, driven by increasing disposable incomes and a growing middle class. This expansion is not just about sales; it’s about adapting products to local tastes and preferences.

Collaborations and PartnershipsTo stay ahead, many companies are forming collaborations and partnerships. These alliances are not just about sharing technology but also about pooling resources to tackle challenges such as environmental impact and product lifecycle management. Data indicates a trend towards strategic partnerships that can lead to groundbreaking innovations.

In conclusion, the industry is undergoing a dynamic shift, driven by consumer demands, technological advancements, and global market trends. The data paints a picture of an industry that is not only evolving but also innovating at a rapid pace, poised to revolutionize the way we interact with our kitchen appliances.

The integration of integrated circuit boards (ICBs) into kitchen appliances has undeniably revolutionized the market, bringing forth a wave of innovation and efficiency. These factories play a pivotal role in shaping the landscape of the appliance industry. Let’s delve into the impact they have on the market.

The precision and sophistication of ICBs have led to appliances that are not just functional but also highly intelligent. Smart kitchen gadgets, such as ovens that can adjust cooking times based on the food’s weight, and refrigerators that can track your inventory and suggest meal plans, are becoming increasingly common. This shift towards smart appliances has been a direct result of the advancements in ICB technology.

One of the most significant impacts of ICB factories on the market is the reduction in size and increase in performance of kitchen appliances. For instance, compact ovens with the same heating capabilities as their larger counterparts have been made possible by the miniaturization of ICBs. This not only saves space in kitchens but also allows for the design of sleek, modern appliances that blend seamlessly into contemporary living spaces.

The rise of energy-efficient appliances is another testament to the influence of ICB factories. With the increasing focus on sustainability, ICBs have enabled appliances that consume less energy while maintaining or even improving their performance. This shift has not only helped consumers save on energy bills but has also contributed to a reduction in the overall carbon footprint of the appliance industry.

Customization has also been greatly enhanced by ICB technology. Appliances can now be programmed to cater to individual preferences and dietary needs, offering a level of personalization that was once unimaginable. This has opened up new markets for niche products, catering to specific health conditions, cultural diets, and lifestyle choices.

The integration of ICBs has also led to a surge in connectivity between kitchen appliances. Smart home systems allow users to control their kitchen appliances remotely, providing convenience and safety. For example, if a user is out and about and realizes they left the oven on, they can turn it off from their smartphone, preventing potential hazards.

The quality control in ICB factories is stringent, ensuring that every board meets high standards of reliability and performance. This reliability has extended to the appliances themselves, reducing the frequency of breakdowns and the need for repairs. This has not only improved customer satisfaction but has also contributed to a more sustainable and cost-effective appliance market.

ICB factories have also spurred competition and innovation among appliance manufacturers. The constant push to incorporate the latest ICB technology has led to rapid advancements in appliance design and functionality. This competition has, in turn, driven down prices, making high-tech appliances more accessible to a wider consumer base.

In the realm of sustainability, ICB factories have played a crucial role in reducing e-waste. By making appliances more durable and repairable, they are helping to extend the lifespan of kitchen gadgets. This shift towards a circular economy is beneficial for both the environment and the consumer.

The market has seen a significant shift towards modular and upgradeable appliances. ICBs have enabled the creation of appliances that can be updated with new features through software updates, much like smartphones. This approach allows manufacturers to keep their products fresh and competitive without needing to replace the entire appliance.

The impact of ICB factories on the market is not limited to kitchen appliances. The technology has also trickled down to other sectors, such as healthcare and home automation. The same principles of miniaturization, efficiency, and connectivity are being applied to create innovative products that enhance daily life.

In conclusion, the role of ICB factories in the appliance market is multifaceted. They have driven innovation, improved efficiency, and increased consumer satisfaction. As the technology continues to evolve, we can expect even more groundbreaking developments that will further transform the way we interact with our kitchen appliances.

The landscape of kitchen appliances is rapidly evolving, with a surge in innovation driven by advancements in integrated circuit boards (ICBs). These microchips are not just a component; they are the beating heart of modern appliances, driving efficiency, functionality, and user experience. Let’s delve into the challenges and opportunities that arise from the impact of ICB factories on the market.

The complexity of today’s kitchen appliances demands highly sophisticated ICBs, capable of managing a multitude of functions. From smart ovens and refrigerators to dishwashers and induction cooktops, each appliance requires precise control and intelligence. This has created a significant demand for high-quality, reliable ICBs.

On one hand, the demand for ICBs in kitchen appliances has led to an increased need for advanced manufacturing capabilities. ICB factories must continuously improve their processes to meet the stringent quality standards set by the appliance industry. This means investing in cutting-edge technology and highly skilled labor to ensure that the microchips meet the high performance requirements of kitchen appliances.

Conversely, the reliance on ICBs has also brought challenges in terms of supply chain disruptions. As these factories are often centralized in specific regions, a global event, such as the COVID-19 pandemic, can severely impact the production and distribution of ICBs. This vulnerability in the supply chain has highlighted the importance of diversifying manufacturing locations and supply sources to mitigate such risks in the future.

The opportunity for ICB factories lies in the ability to adapt and innovate. With the rise of smart kitchens and the Internet of Things (IoT), there is a growing need for ICBs that can support interconnectivity and data management. Factories that can develop and produce these advanced ICBs are poised to become key players in the appliance industry.

In terms of product design, ICB factories have the chance to push the boundaries of what kitchen appliances can offer. Imagine a refrigerator that not only keeps your food fresh but also predicts when you’re about to run out of staple items and reorders them automatically. The ICBs inside would need to process data from the refrigerator, your shopping habits, and even external factors like seasonal produce availability to make such a system possible.

Energy efficiency is another critical area where ICB factories can play a pivotal role. With increasing environmental concerns, the industry is pushing for appliances that consume less energy while still delivering the same level of performance. ICBs that can optimize energy usage and manage energy-efficient modes are becoming more important. Factories that can design and manufacture these specialized ICBs will be at the forefront of this green revolution.

However, there’s a challenge in ensuring that the technology is accessible to a wide range of consumers. As the capabilities of ICBs in appliances increase, so does the cost. This could potentially create a divide between high-end appliances and those aimed at more budget-conscious consumers. ICB factories must balance the drive for innovation with the need to make smart appliances affordable and accessible.

Security is another challenge that ICB factories cannot overlook. With appliances becoming more connected, the risk of cyber threats also increases. Ensuring that the ICBs used in these devices are secure from hacking and unauthorized access is paramount. This requires not just robust hardware but also the development of sophisticated software and encryption methods.

Finally, the opportunity for ICB factories to collaborate with appliance manufacturers is immense. By working closely together, they can develop solutions that address specific needs and preferences of consumers. This collaboration can lead to co-created appliances that not only integrate seamlessly into a kitchen environment but also provide a unique and personalized experience.

In conclusion, the role of ICB factories in the kitchen appliance market is multifaceted. They must navigate the challenges of complex manufacturing, supply chain resilience, and cost-effectiveness while embracing the opportunities to innovate, secure appliances, and drive sustainability. By doing so, they can be instrumental in shaping the future of kitchen technology and the lives of consumers around the world.

In the heart of the tech-driven appliance industry, there exists a beacon of innovation—a leading ICB factory that has redefined the landscape of kitchen appliances. This factory, known for its cutting-edge technology and strategic partnerships, has left an indelible mark on the market. Let’s delve into the impact it has had through a case study that encapsulates its journey.

The factory’s inception was marked by a vision to merge the precision of electronics with the practicality of kitchenware. From the very beginning, it focused on creating ICBs that could enhance the performance and functionality of kitchen appliances. Over the years, here’s how its influence has rippled through the market:

The factory’s commitment to research and development has led to the creation of ICBs that are not only efficient but also energy-saving. These advancements have sparked a wave of energy-conscious consumers who are increasingly looking for appliances that minimize their carbon footprint.

One of the standout products from this factory is the smart oven with an ICB that allows for precise temperature control and multi-level cooking. This has transformed the way consumers think about baking and roasting, leading to a surge in demand for smart kitchen appliances that offer versatility and convenience.

The factory’s ICBs have also played a crucial role in the miniaturization of kitchen appliances. The compact, high-performance ICBs have enabled the creation of space-saving appliances that are perfect for urban dwellers and those with limited kitchen space. This shift has opened up new market segments and has been particularly influential in Europe, where kitchen space is often at a premium.

Innovation in connectivity has been another area where this factory has made significant strides. The ICBs they produce are designed to seamlessly integrate with home automation systems, allowing for remote control and monitoring of appliances. This has not only changed the way consumers interact with their kitchen tools but has also paved the way for the Internet of Things (IoT) in the culinary domain.

The factory’s ICBs have also been instrumental in enhancing the user interface of kitchen appliances. With intuitive touchscreens and voice-activated controls, appliances are becoming more user-friendly, appealing to a broader audience, including the elderly and those with disabilities. This has not only expanded the market but has also fostered a sense of inclusivity in kitchen design.

Safety has always been a top priority for this leading ICB factory, and their products reflect that commitment. The inclusion of safety features like automatic shut-offs and child locks has made kitchen appliances more reliable and has given consumers peace of mind. This focus on safety has helped the factory to establish a reputation for trustworthiness in the industry.

Another notable impact of this factory’s ICBs is the reduction in the cost of production for kitchen appliances. By streamlining the design and functionality, the factory has enabled manufacturers to produce more affordable appliances without compromising on quality. This has democratized kitchen technology, making it accessible to a wider range of consumers.

The factory’s ICBs have also contributed to the rise of personalized kitchen appliances. With the ability to tailor settings and recipes to individual preferences, consumers are experiencing a more customized cooking experience. This level of personalization has been a game-changer in the appliance market, as it aligns with the current trend towards customization and personalization across various consumer goods.

The factory’s impact extends beyond the appliance market itself. It has inspired a new wave of startups and entrepreneurs who are looking to innovate in the kitchen technology space. The factory’s success has set a precedent for what is possible with ICBs, encouraging others to push the boundaries of what kitchen appliances can do.

In conclusion, the leading ICB factory’s impact on the market has been profound. From driving innovation and efficiency to fostering safety and customization, its products have redefined the landscape of kitchen appliances. The factory’s commitment to excellence and its ability to anticipate market trends have positioned it as a leader in the industry, and its influence is likely to continue shaping the future of kitchen technology for years to come.

The integration of integrated circuit boards (ICBs) into kitchen appliances has transformed the way we interact with our kitchen tools. Consumers are reaping numerous benefits, and the market potential for these advanced appliances is vast and growing.

Enhanced Efficiency and PerformanceICBs have significantly improved the efficiency and performance of kitchen appliances. Smart ovens, for instance, can precisely control cooking temperatures and times, ensuring optimal results every time. The precise control offered by ICBs reduces energy consumption and preserves food quality, leading to cost savings and a more sustainable kitchen environment.

User-Friendly InterfacesWith ICBs, kitchen appliances now feature intuitive interfaces that make them easier to use. Touchscreens, voice commands, and even augmented reality (AR) have become common, allowing users to navigate settings and recipes with ease. This user-friendly approach has broadened the appeal of kitchen appliances to all skill levels, from beginners to seasoned chefs.

Customization and PersonalizationICBs enable appliances to learn from user habits and preferences, offering a level of customization that was once unimaginable. Smart refrigerators, for example, can suggest meal plans based on the ingredients you have and your dietary needs. This level of personalization not only simplifies meal prep but also encourages healthier eating habits.

Connectivity and IntegrationThe integration of ICBs has also led to greater connectivity between kitchen appliances. Smart devices can communicate with each other, allowing for seamless cooking processes. Imagine a scenario where your oven automatically adjusts its temperature based on the progress of your induction cooktop. This interconnectedness creates a cohesive kitchen ecosystem that streamlines meal preparation.

Data-Driven InsightsICBs in kitchen appliances collect and analyze data, providing valuable insights into usage patterns and energy consumption. Manufacturers can use this information to optimize their products, while consumers can gain a better understanding of their kitchen habits. For instance, a smart coffee maker might suggest a more efficient brewing cycle, leading to energy savings and a fresher cup of coffee.

Health and Safety FeaturesICBs have also introduced advanced health and safety features into kitchen appliances. Smart appliances can monitor cooking temperatures and times, alerting users to potential hazards such as undercooking or overheating. Additionally, features like child locks and automatic shut-offs in ovens and stovetops provide peace of mind for busy households.

Market Potential ExpansionThe market potential for ICB-enhanced kitchen appliances is substantial. As consumers become more tech-savvy and environmentally conscious, the demand for smart, efficient, and personalized appliances is on the rise. The integration of ICBs allows manufacturers to cater to these evolving needs, opening up new opportunities for growth and innovation.

Economic ImpactThe adoption of ICBs in kitchen appliances has a significant economic impact. It drives job creation in manufacturing, software development, and customer service sectors. Moreover, as appliances become more energy-efficient, there is a positive effect on the economy due to reduced energy costs for consumers and businesses.

Global ReachThe market for ICB-enhanced kitchen appliances is not limited to a single region. It’s a global trend that is influencing consumers worldwide. As technology continues to advance, the gap between developed and developing countries in terms of kitchen appliance sophistication is narrowing, creating a more uniform market landscape.

Long-Term SustainabilityThe integration of ICBs in kitchen appliances contributes to long-term sustainability efforts. By promoting energy efficiency and reducing waste, these appliances help to preserve natural resources and combat climate change. As consumers become more aware of these benefits, the market for eco-friendly kitchen appliances is expected to grow further.

ConclusionThe benefits of ICBs in kitchen appliances are multifaceted, offering consumers enhanced efficiency, convenience, and safety. The market potential for these innovations is immense, with a global reach and the potential to drive economic growth and sustainability. As technology continues to evolve, the future of kitchen appliances looks bright, promising a seamless and intelligent cooking experience for all.

The integration of technology in kitchen appliances has transformed the way we interact with our daily cooking routines. From simple appliances like toasters and blenders to complex systems like smart refrigerators and induction cooktops, the role of integrated circuit boards (ICBs) has become indispensable. These tiny, yet powerful, components are the heart of modern kitchen innovation, offering precision, efficiency, and connectivity. Let’s delve into the myriad ways ICBs are reshaping the landscape of kitchen appliances.

In the realm of smart appliances, ICBs enable a level of connectivity that was once unimaginable. Ovens equipped with ICBs can now communicate with your smartphone, providing real-time cooking updates and adjusting settings based on your preferences. The same goes for dishwashers, which can optimize their cleaning cycles based on the type of load and water availability. This level of intelligence not only simplifies the cooking process but also ensures that appliances are using resources efficiently.

The European and American markets have been at the forefront of adopting these technological advancements. European consumers, known for their preference for high-quality, eco-friendly products, are particularly drawn to appliances that offer energy-saving capabilities. ICBs play a crucial role in this, allowing for more precise control over energy use, thus reducing utility bills and environmental impact.

In the United States, the market is characterized by a strong focus on convenience and innovation. American consumers are eager to embrace the latest in smart technology, and ICBs are at the core of this trend. From refrigerators that can track your groceries to microwaves that can defrost and reheat food with a simple tap, the possibilities are vast.

The European and American market dynamics are shaped by a blend of factors. Consumer behavior, cultural preferences, and regulatory frameworks all play a significant role. For instance, the European Union’s strict energy efficiency standards have pushed manufacturers to develop more advanced ICBs that not only enhance performance but also meet environmental regulations.

Innovation in ICBs for kitchen appliances is not just about adding new features. It’s about creating a seamless, intuitive experience that makes cooking more enjoyable and less time-consuming. One such innovation is the integration of voice recognition technology. With ICBs, appliances can now respond to voice commands, allowing users to control their kitchen gadgets without lifting a finger.

Another area of innovation is the use of ICBs in creating personalized cooking experiences. Appliances can be programmed to remember your preferences, whether it’s the temperature you like your coffee at or the exact timing for your favorite dish. This level of personalization not only enhances the user experience but also adds a layer of convenience that is hard to match.

Data analysis has become a key component in the development of ICBs. By analyzing usage patterns and feedback from consumers, manufacturers can refine their products to better meet market demands. For example, if a certain model of oven is not living up to expectations, the data can guide engineers in making necessary adjustments to improve performance.

The impact of ICB factories on the market is undeniable. These factories are the backbone of the industry, producing the intricate circuits that power the latest kitchen gadgets. They must balance the need for innovation with the demands of scalability and cost-effectiveness. As the market continues to evolve, these factories are under pressure to keep pace with the rapid advancements in technology.

Challenges and opportunities coexist in this dynamic environment. On one hand, there’s the challenge of keeping up with the pace of technological change. On the other hand, there’s the opportunity to lead the market with cutting-edge solutions. Factories that can adapt quickly and efficiently will be the ones that succeed in this competitive landscape.

One notable case study is the partnership between a leading ICB factory and a major appliance manufacturer. This collaboration resulted in the development of a smart oven that could be controlled remotely through a smartphone app. The oven’s ICBs were designed to handle complex algorithms that allowed for precise temperature control and energy management. The success of this product not only boosted sales but also set a new standard for smart kitchen appliances.

Consumer benefits are clear. With ICBs, kitchen appliances are not just tools but companions that can enhance daily life. They offer convenience, efficiency, and the ability to tailor cooking experiences to individual preferences. The market potential for these benefits is enormous, as more consumers become aware of the possibilities and seek to integrate smart technology into their homes.

As we look to the future, the outlook for ICBs in kitchen appliances is bright. The continued advancements in technology, coupled with the growing demand for smart appliances, suggest a robust market ahead. ICB factories will need to focus on areas such as miniaturization, energy efficiency, and enhanced processing capabilities to keep up with the evolving needs of consumers.

In conclusion, the role of ICBs in kitchen appliances is pivotal. They are the driving force behind the smart kitchen revolution, offering consumers a world of possibilities. The European and American markets are leading the charge, and the challenges and opportunities that come with this role are being met with innovation and determination. The future of kitchen appliances is bright, and ICBs are at the forefront of this exciting journey.