Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

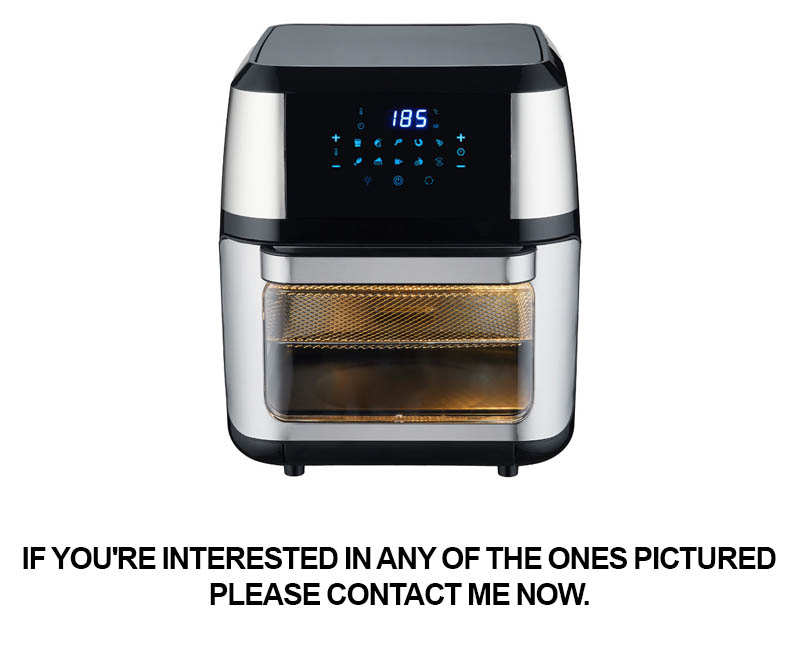

In the ever-evolving world of culinary delights, the humble panini has soared to new heights, becoming a staple on many a menu. With the rise of industrial panini presses, the art of grilling and pressing these delightful sandwiches has been elevated to a whole new level. These innovative appliances are not just for the casual cook at home; they’re changing the landscape of professional kitchens as well. Let’s delve into why these presses are becoming the go-to choice for both home chefs and industry professionals alike.

The kitchen, once a realm of simmering pots and sizzling pans, has seen a surge in technological innovation, with one standout gadget leading the charge: the industrial panini press. This marvel of modern cuisine has quietly risen to prominence, transforming the way we think about sandwiches and the art of cooking them. From cafes to restaurants, the industrial panini press has become a game-changer, redefining the standards of sandwich-making.

Once the domain of home cooks and casual diners, the sandwich has now found its way into the hearts of chefs and culinary professionals. The industrial panini press is not just a tool for pressing bread; it’s a key player in the quest for culinary excellence. With its sturdy build and powerful heating elements, it’s designed to handle the demands of a busy kitchen, ensuring consistent results time after time.

The rise of the industrial panini press can be attributed to several factors. For one, the demand for fast and convenient food has never been higher. As consumers seek quick meal options, the panini press offers a solution that is both delicious and efficient. Its ability to cook a sandwich in mere minutes makes it an ideal choice for busy cafes and delis, where time is of the essence.

Moreover, the versatility of the industrial panini press cannot be overstated. It’s not just for pressing sandwiches; it can also be used to toast bread, cook wraps, and even sear vegetables. This multifunctionality has made it a must-have for chefs looking to expand their menu offerings without the need for additional equipment.

In the past, the thought of a sandwich being cooked to perfection in a commercial setting was a far-fetched dream. The industrial panini press has changed that narrative. With its ability to achieve a perfect golden-brown crust and a melty, gooey filling, it has set a new benchmark for sandwich quality. The even heat distribution ensures that every bite is uniformly cooked, a feat that was once challenging to achieve with traditional cooking methods.

The design of the industrial panini press has also evolved to meet the needs of modern kitchens. Many models now come with adjustable heat settings, allowing chefs to tailor the cooking temperature to the specific ingredients they are using. This level of control is crucial for achieving the desired level of crispiness or softness in the bread, making every sandwich a custom creation.

In terms of durability, the industrial panini press is a beast. Constructed with heavy-duty materials, it can withstand the rigors of a commercial kitchen environment. Its sturdy handles and reliable locking mechanisms ensure that it can be used for years without faltering. This longevity is a significant factor for businesses looking to invest in equipment that will last.

The market for industrial panini presses has seen a surge in competition, with several brands vying for a spot on the shelves of professional kitchens. This competition has led to a proliferation of features and innovations, from non-stick surfaces to digital temperature controls. Chefs now have a plethora of options to choose from, each designed to enhance their cooking experience.

The rise of the industrial panini press has also had a ripple effect on the culinary world. Chefs and bakers are now experimenting with different breads, fillings, and cooking techniques to take full advantage of the press’s capabilities. This has led to a surge in creativity, with new sandwich variations and recipes popping up almost daily.

For those looking to enter the commercial kitchen scene, the industrial panini press is a gateway to success. It’s a tool that can help new businesses stand out by offering a unique menu item that is both trendy and satisfying. The press’s ability to produce high-quality sandwiches quickly and consistently makes it an invaluable asset for any establishment aiming to serve delicious, fast food.

In conclusion, the industrial panini press has emerged as a pivotal player in the kitchen, reshaping the landscape of sandwich-making. Its convenience, versatility, and ability to deliver restaurant-quality results have made it an indispensable tool for chefs and culinary professionals alike. As the demand for quick, delicious meals continues to grow, the industrial panini press is poised to remain a game-changer in the kitchen for years to come.

Industrial panini presses have emerged as a formidable force in the commercial kitchen, transforming the way we think about sandwich preparation. These robust appliances are not just your average kitchen gadget; they are precision instruments designed for the demands of high-volume cooking. Let’s delve into what sets these industrial panini presses apart from their domestic counterparts.

Their build quality is the first thing that strikes you. Industrial models are crafted with durability in mind, often featuring stainless steel bodies and heavy-duty construction. This robustness is essential in environments where constant use and exposure to heat and moisture are the norm.

The size and capacity of industrial panini presses are significantly larger than those found in home kitchens. These machines can accommodate multiple sandwiches at once, which is crucial for maintaining a steady flow of food during busy service times. The ability to cook several paninis simultaneously not only increases efficiency but also ensures consistent heat distribution across all the sandwiches.

One of the standout features of industrial panini presses is their even heating capabilities. Unlike home appliances, which may struggle to maintain a consistent temperature across the entire press, industrial models are calibrated to provide uniform heat across the entire cooking surface. This means that every sandwich comes out perfectly toasted, with a perfect blend of crispy and soft textures.

The controls on industrial panini presses are also a cut above. These machines often come with precise temperature settings and adjustable timers, allowing chefs to fine-tune the cooking process to suit different types of bread and fillings. This level of control is vital in commercial settings where consistency is key to customer satisfaction.

Safety features are another area where industrial panini presses excel. They are equipped with safety locks to prevent accidental opening while in operation, as well as heat-resistant handles and surfaces. This ensures that staff can work safely and efficiently without the risk of burns or other accidents.

The speed at which industrial panini presses can cook is remarkable. These machines are designed to handle a high volume of food quickly, reducing waiting times for customers and increasing throughput. This is particularly beneficial in fast-food and quick-service restaurants where time is of the essence.

In terms of versatility, industrial panini presses can cook a wide variety of sandwiches, not just the classic ham and cheese. They are capable of grilling, searing, and melting cheese, making them ideal for gourmet sandwiches, wraps, and even some main dishes. This flexibility allows chefs to offer a diverse menu without the need for multiple appliances.

The cleaning process for industrial panini presses is also designed with convenience in mind. Many models feature removable plates and components that can be easily cleaned in a commercial dishwasher, saving time and effort in the kitchen.

The design of industrial panini presses also reflects an understanding of kitchen ergonomics. They are often equipped with features like adjustable legs and compact designs that save space without compromising on functionality. This attention to detail ensures that the appliance fits seamlessly into any kitchen setup.

Lastly, the reputation and brand behind an industrial panini press can be a testament to its quality. Established manufacturers with a history of producing commercial-grade equipment are known for their reliability and longevity, making their products a wise investment for any business.

In summary, the industrial panini press is a specialized piece of equipment that stands out due to its robust build, large capacity, even heating, precise controls, safety features, speed, versatility, ease of cleaning, ergonomic design, and brand reputation. It’s an essential tool for any commercial kitchen looking to offer high-quality, consistent sandwiches with ease and efficiency.

The landscape of kitchen appliances has been continuously evolving, and the industrial panini press is no exception. These presses have seen a surge in innovation, transforming from simple gadgets to sophisticated machines that cater to both commercial and home use. Let’s delve into the design innovations that have set the industrial panini press apart.

The heat distribution has been a cornerstone of panini press evolution. Early models often suffered from uneven heat, leading to inconsistent results. Modern industrial presses now feature advanced heating elements that ensure uniform heat across the entire cooking surface. This innovation has significantly reduced the number of burnt or undercooked sandwiches, making for a more enjoyable experience for both the operator and the consumer.

One of the latest design trends is the integration of adjustable temperature controls. This allows users to tailor the cooking temperature to different types of bread and fillings, ensuring that each panini is cooked to perfection. Some models even come with digital displays that show the exact temperature, giving users peace of mind and precise control over the cooking process.

The construction materials used in industrial panini presses have also seen a revolution. Many older models were made from heavy metals that were durable but less than ideal for handling. Today, manufacturers are opting for lighter, yet robust materials like stainless steel and aluminum alloys. These materials not only reduce the weight of the press but also contribute to better heat retention and a sleeker design.

The design of the cooking plates has also evolved. Traditional panini presses had flat surfaces that were great for sandwiches, but they lacked versatility. Modern industrial presses often come with non-stick surfaces that are perfect for a variety of foods, not just sandwiches. Some models even feature reversible plates with different textures, allowing for a range of cooking styles from crispy to soft.

Safety features have become a significant focus in the design of industrial panini presses. Locking mechanisms have been improved to prevent accidental openings while cooking, reducing the risk of burns. Some models now include cool-touch handles and surfaces, ensuring that the operator can safely move the press without worrying about high temperatures.

In terms of size and portability, there has been a shift towards compact and versatile designs. Industrial panini presses are now available in various sizes, from countertop models to larger units designed for commercial kitchens. The compact designs are not only space-saving but also make it easier to transport the press to different locations if needed.

The user interface has also seen improvements. Modern industrial presses often feature intuitive controls, including push-button temperature settings and easy-to-read displays. This has made the machines more accessible to a broader range of users, from busy chefs to home cooks looking to add a touch of professionalism to their cooking.

The inclusion of additional features has further expanded the capabilities of industrial panini presses. Many models now come with built-in timers, allowing users to set precise cooking times for different types of paninis. Some even have a defrost function, making it easier to prepare sandwiches with frozen ingredients.

The evolution of the industrial panini press is a testament to the ingenuity of appliance designers. From improved heat distribution to safety features and user-friendly interfaces, these innovations have made the panini press a staple in both commercial kitchens and home cooking setups. As technology continues to advance, we can expect even more innovative designs that will further elevate the art of panini cooking.

In the bustling world of commercial kitchen equipment, the industrial panini press has emerged as a trendsetter, reshaping the way food is prepared and served. As demand for high-quality, fast-casual meals continues to soar, the market for these specialized presses has expanded significantly. Let’s take a closer look at the key players and what sets them apart in the dynamic landscape of industrial panini presses.

The market leaders in the industrial panini press sector are not just known for their products but also for their innovative approaches to design and customer service. One such brand, for instance, has revolutionized the industry with its sleek, high-efficiency presses that cater to both small cafes and bustling restaurants. Their presses are not just about pressing; they are designed to enhance the overall cooking experience.

Another prominent player has carved out a niche with its eco-friendly line of panini presses. These models are not only energy-efficient but also constructed with sustainable materials, appealing to a growing segment of environmentally conscious consumers. The brand’s commitment to sustainability is reflected in every aspect of their product, from the manufacturing process to the end-user experience.

The competition is fierce, with several manufacturers focusing on specific features that differentiate their presses from the rest. Some have introduced adjustable pressure settings, allowing chefs to customize the cooking process for different types of sandwiches. This level of control is crucial for maintaining consistency and ensuring that each panini is cooked to perfection.

Moreover, the integration of modern technology has become a hallmark of top-tier industrial panini presses. Smart features like digital temperature controls and timers are now standard, making it easier for operators to manage the cooking process with precision. These technological advancements not only streamline operations but also contribute to the overall quality of the final product.

In the realm of aesthetics, there’s a noticeable shift towards compact and space-saving designs. This is particularly important for establishments with limited kitchen space, as an efficient panini press can be a game-changer in terms of maximizing available area. The sleek, modern look of these presses also aligns with the contemporary design ethos of many modern restaurants.

The market for industrial panini presses is not just about the equipment itself; it’s about the entire ecosystem that surrounds it. Top brands offer comprehensive support services, including training for staff, maintenance programs, and even the option for customization. This holistic approach to customer satisfaction has become a key differentiator in a crowded market.

In terms of pricing, the industrial panini press market spans a wide range, catering to different budgets and business sizes. Entry-level models are often priced competitively, making them accessible to small businesses and startups. On the higher end, premium presses with advanced features can command a premium price, targeting mid to high-end restaurants and food service operations.

The rise of the food truck and pop-up culture has also influenced the market landscape, with manufacturers creating portable and rugged panini presses that can withstand the rigors of mobile operations. These versatile models are often equipped with features that make them easy to clean and maintain, ensuring that they can be used on the go without compromising on performance.

The industrial panini press trend is also being driven by the demand for diverse menu offerings. As consumers seek a variety of food options, restaurants are looking to expand their sandwich selections. The ability to cook different types of bread, from traditional paninis to brioche and baguettes, has become a key selling point for these presses.

In conclusion, the market landscape for industrial panini presses is characterized by a blend of innovation, customer focus, and technological advancement. With a range of options available, businesses can choose the perfect press to meet their specific needs, whether it’s for a high-volume restaurant or a niche café. The leaders in this space are not just pushing the boundaries of what a panini press can do but are also shaping the future of the food service industry.

The art of crafting a perfect panini at home can be a delightful journey, bridging the gap between casual cooking and gourmet dining. Whether you’re a culinary enthusiast or a busy home chef, mastering the technique of making restaurant-quality paninis is well within reach. Here are some tips and tricks to help you achieve that golden, crispy exterior and mouthwatering melt-in-your-mouth interior.

The Key to Consistent Heat DistributionOne of the most crucial aspects of making a great panini is ensuring even heat distribution. The key to this lies in your panini press. Invest in a high-quality model with a non-stick surface and even heating elements. This way, you can be confident that each slice of bread will brown evenly, and your fillings will melt just right.

Selecting the Right BreadChoosing the right bread is fundamental. Opt for a thick-cut, ciabatta, or sourdough bread for that classic panini texture. Avoid using overly soft or thin breads, as they might not achieve the desired crunch. For an extra layer of flavor, consider toasting the bread lightly before assembling your sandwich.

Balancing the FlavorsA great panini isn’t just about the bread; it’s all about the fillings. Balance is key. Think about the flavors and textures you want to achieve. Use a variety of meats, cheeses, vegetables, and spreads. For example, a combination of prosciutto, fontina cheese, arugula, and a hint of balsamic glaze can create a sophisticated yet satisfying sandwich.

Layering Your IngredientsWhen assembling your panini, it’s essential to layer the ingredients in an organized and logical manner. Place the heaviest items like cheeses and wetter ingredients at the bottom to prevent them from onto the bottom slice of bread. Add your meats and vegetables next, and finish with a light spread or a delicate cheese for added flavor without overpowering the rest of the filling.

The Art of PressingPressing the panini press down is more of a gentle press rather than a heavy clamp. The goal is to seal the sandwich and apply even pressure without crushing the bread or squashing the fillings. Use a gentle, even motion to close the press, and be patient; it may take a few seconds for the sandwich to adhere properly.

Timing is EverythingEvery panini has its own timing, and it’s crucial to learn the rhythm. For a medium-to-soft panini, 3 to 4 minutes on each side should suffice. For a perfectly toasted, crispy crust, aim for closer to 5 minutes. Use a thermometer to check the internal temperature of your panini, aiming for around 160°F (71°C) for the fillings to be safe and the cheese to be melted.

Using the Right CheeseCheese is the soul of a panini. Choose a cheese that complements your fillings and adds the right amount of richness. Cheese slices that are too thin can melt too quickly, while those that are too thick might overpower the other ingredients. Experiment with different cheeses to find the perfect match for your taste.

Avoiding OvercookingOne common pitfall is overcooking the panini, which can result in a tough and rubbery texture. Keep an eye on your sandwich, and if you notice that the bread is browning too quickly or the cheese is starting to burn, remove it from the press and lower the temperature if your model allows for it.

Customizing Your PaniniDon’t be afraid to get creative with your panini. Add a dash of herbs, a swipe of mustard or mayonnaise, or a dollop of aioli for a personal touch. Sometimes, the simplest additions can elevate a panini from good to extraordinary.

Finishing TouchesOnce your panini is done, let it sit for a moment before slicing it. This allows the steam to release and the flavors to meld together. Slice it diagonally for an attractive presentation, and serve immediately. A few extra spritzes of olive oil or a sprinkle of salt can also enhance the overall appeal.

In conclusion, achieving restaurant-quality paninis at home is all about the right tools, ingredients, and technique. With these tips, you can create a delicious, homemade version of this beloved sandwich that’s sure to impress guests and satisfy your culinary desires.

In the bustling world of foodservice, the industrial panini press has emerged as a cornerstone for entrepreneurs looking to capitalize on the growing demand for quick, delicious, and customizable sandwiches. Here’s a closer look at the business opportunities that this market presents.

The surge in popularity of paninis has been fueled by their versatility and the convenience they offer. As consumers seek out unique flavors and fast-casual dining experiences, entrepreneurs are finding that the industrial panini press is not just a tool but a gateway to a thriving business.

One of the key opportunities lies in the customization that these presses allow. By offering a variety of breads, meats, cheeses, and toppings, businesses can cater to diverse dietary preferences and restrictions, from gluten-free to vegan options. This flexibility means that as trends shift, so too can the menu, ensuring that the business remains relevant and appealing to a broad customer base.

The industrial panini press market is also seeing a rise in eco-friendly options. With sustainability becoming a significant concern for consumers, businesses that invest in energy-efficient presses and promote sustainable sourcing of ingredients can attract environmentally conscious customers. This not only benefits the planet but also opens up a niche market that is increasingly sought after.

Moreover, the rise of food trucks and pop-up restaurants has created a demand for portable and durable panini presses. Entrepreneurs with a passion for mobile dining can leverage the compact size and robust design of these presses to set up shop almost anywhere, from street corners to festivals, creating a dynamic and ever-changing menu that keeps customers coming back for more.

For those looking to establish a brick-and-mortar establishment, the industrial panini press market offers a unique opportunity to create a niche spot. Think of a panini café or a gourmet sandwich shop, where the focus is on the art of the panini. This can range from a cozy, rustic setting to a sleek, modern bistro, depending on the target demographic.

The technology behind industrial panini presses is also advancing, offering new features that can set one business apart from another. For instance, some models now come with adjustable heat settings, allowing for perfecting the cooking temperature to suit different ingredients. Others have added safety features, like automatic shut-offs and non-slip bases, which not only protect the operator but also enhance the customer experience.

Marketing and branding play a crucial role in the success of an industrial panini press business. By focusing on the unique selling points of the product, such as the speed of service, the quality of the ingredients, or the innovative design of the press, entrepreneurs can create a strong brand identity. Social media and influencer partnerships can help spread the word, especially in a world where word-of-mouth and online reviews are powerful drivers of consumer choice.

Another opportunity lies in the integration of technology. Apps and online ordering systems can streamline the customer experience, making it easier for patrons to order and pay without waiting in line. This can be particularly beneficial in high-traffic areas where time is of the essence.

For entrepreneurs with a passion for food and business, the industrial panini press market is ripe with potential. Whether it’s through offering a unique dining experience, embracing sustainability, or leveraging technology, there are numerous ways to carve out a successful niche. The key is to stay informed about market trends, understand the needs of your target audience, and be ready to adapt as the industry evolves. With the right approach, the industrial panini press can be more than just a tool—it can be the cornerstone of a thriving business.

The surge in popularity of industrial panini presses has sparked a wave of interest among consumers, but what drives this trend? Here are some insights into why these appliances are catching on like wildfire:

In recent years, there’s been a significant shift in the way people think about cooking at home. The convenience of fast-paced lifestyles has led to a renewed appreciation for quick yet satisfying meals. The industrial panini press taps into this desire for efficiency and deliciousness, offering a solution that doesn’t compromise on flavor.

The rise of social media and food influencers has also played a crucial role in promoting the industrial panini press. These platforms showcase the versatility of the appliance, from classic sandwiches to creative culinary masterpieces. The visual appeal of perfectly toasted bread with visible layers and melted cheese is hard to resist, and it’s all thanks to the even heat distribution of these presses.

Another key factor is the convenience factor. Unlike traditional toasters or grills, an industrial panini press can handle multiple slices of bread at once, making it perfect for families or those hosting gatherings. This efficiency is a game-changer for busy individuals looking to serve a crowd without sacrificing quality.

The industrial panini press also caters to a health-conscious consumer base. With the growing trend of homemade meals over processed snacks, these presses offer a healthier alternative to fast food. They allow users to control the ingredients, making it easier to avoid additives and preservatives commonly found in store-bought sandwiches.

Moreover, the versatility of the industrial panini press extends beyond sandwiches. Users can experiment with different fillings, including vegetables, meats, and even sweet ingredients like fruits and jams. This versatility turns the press into a multipurpose kitchen tool, capable of creating a variety of recipes from simple to gourmet.

One cannot ignore the nostalgia factor either. The smell of freshly toasted bread and melted cheese evokes memories of childhood, picnics, and family gatherings. The industrial panini press brings this nostalgic experience into modern homes, reminding us of the simple pleasures in life.

As the demand for the industrial panini press continues to grow, manufacturers are responding with innovative features. New models now come with adjustable heat settings, non-stick surfaces, and even customizable press options. These features cater to a wider range of preferences and cooking styles, ensuring that everyone can achieve the perfect panini.

Additionally, the environmental benefits of using an industrial panini press are becoming increasingly apparent. By opting for a reusable appliance that can create a variety of homemade meals, consumers are reducing their carbon footprint and promoting sustainability.

Lastly, the cost-effectiveness of the industrial panini press cannot be overlooked. While it may seem like a luxury item, the long-term savings from homemade meals, coupled with the ability to experiment with recipes, make it a worthwhile investment for many families.

In conclusion, the industrial panini press’s popularity can be attributed to its convenience, versatility, health benefits, nostalgia, and innovative design. As more consumers seek to improve their culinary skills and enjoy the comfort of homemade meals, the industrial panini press is poised to remain a sought-after kitchen gadget for years to come.

The industrial panini press has seen a surge in popularity, driven by a combination of consumer demand for convenience and quality, as well as the culinary trends that favor compact, portable, and high-performance kitchen appliances. Let’s delve into why these presses are becoming a staple in many homes and restaurants alike.

Gone are the days when panini sandwiches were a casual weekend treat. The industrial panini press has transformed the way we cook these delightful pressed sandwiches, bringing a level of consistency and flavor that was once only achievable in professional kitchens. With features like adjustable heat settings, non-stick surfaces, and even built-in grilling options, these presses are not just for toasting bread anymore.

The design of industrial panini presses has seen a remarkable evolution. Early models were straightforward, often with simple heating elements and limited adjustability. However, modern presses now come with sleek, user-friendly interfaces that allow for precise temperature control. The inclusion of digital displays and timers has made these appliances more intuitive and reliable. Moreover, some models now boast variable pressure settings, which means you can achieve that perfect crunch on the outside while keeping the inside tender and juicy.

The market for industrial panini presses is heating up, with several key players leading the charge. Established brands like Breville and Cuisinart have expanded their offerings to include more powerful and versatile presses. Meanwhile, newer entrants are bringing fresh designs and innovative features to the table. For instance, some brands are integrating Bluetooth connectivity, allowing users to control their presses remotely through a smartphone app. This integration of technology not only adds convenience but also opens up new possibilities for customization and automation.

One of the most appealing aspects of industrial panini presses is their ability to produce restaurant-quality results at home. Achieving this level of perfection doesn’t have to be complicated. Here are a few tips to help you press the right way:

For entrepreneurs, the industrial panini market presents a world of opportunities. As the demand for convenience and high-quality food continues to grow, there’s room for innovative business models. Consider these ideas:

Consumers are increasingly interested in the industrial panini press due to several factors. The convenience of making a gourmet sandwich at home is hard to beat, especially for busy individuals who appreciate the ease of use and the speed at which these presses operate. Additionally, the health-conscious trend has led many to seek out healthier alternatives to fast food, and the panini press offers a way to create a satisfying meal with minimal oil and preservatives.

The rise of the industrial panini press is also tied to the growing popularity of comfort food. People are looking for a touch of nostalgia in their meals, and the warm, melty cheese and toasted bread of a panini perfectly captures that sentiment. Moreover, the press’s ability to cook a variety of foods—such as flatbreads, wraps, and even pancakes—means it can be a versatile addition to any kitchen.

As we look to the future of panini cooking, several trends and technological advancements are on the horizon. Smart appliances that can be controlled remotely or even through voice commands are becoming more common. This means that the panini press could soon be a part of an interconnected kitchen, where multiple appliances work together to create a perfect meal.

Another trend is the customization of cooking surfaces. Some presses are now offering interchangeable plates, allowing users to achieve different textures and finishes, from a traditional panini to a grilled cheese or even a smoked flavor. This kind of flexibility caters to the consumer’s desire for unique and personalized culinary experiences.

In conclusion, the industrial panini press is more than just a kitchen gadget; it’s a symbol of the changing landscape of home cooking. With its ability to deliver restaurant-quality results, its convenience, and its versatility, it’s no wonder that the panini press is catching on with both consumers and entrepreneurs alike. The future of panini cooking is bright, with endless possibilities for innovation and culinary exploration.

In the competitive world of professional kitchens, the industrial panini press has emerged as a versatile and indispensable tool. Its ability to deliver consistent, high-quality results has made it a staple in many commercial kitchens. Let’s delve into why every professional kitchen should consider incorporating an industrial panini press into their repertoire.

The industrial panini press is not just a device for making sandwiches; it’s a game-changer that enhances the culinary experience. Its even heat distribution ensures that every layer of the sandwich is cooked to perfection, with a beautifully browned exterior and a juicy interior. This level of control over the cooking process is something that traditional grills or toasters simply cannot offer.

Moreover, the industrial panini press is designed with durability in mind. Constructed from heavy-duty materials, these presses can withstand the rigors of a busy kitchen environment. They are built to last, which means fewer repairs and replacements, saving both time and money in the long run.

Innovation in the design of industrial panini presses has led to features that make them even more appealing to professional chefs. Many models now come with adjustable heat settings, allowing for customization of cooking temperatures. This is particularly useful when preparing sandwiches with different ingredients that require varying levels of heat. Additionally, some presses are equipped with non-stick surfaces that make cleaning a breeze, ensuring that the focus remains on the food rather than the maintenance.

The versatility of the industrial panini press is another key factor. It can be used to cook a wide variety of foods, from classic paninis to grilled cheese, burgers, and even flatbreads. This flexibility means that chefs can expand their menu options without the need for additional equipment, thus streamlining kitchen operations.

When it comes to the market landscape, several brands have stepped up to lead the industrial panini press trend. Brands like Breville, Rösle, and NuWave have earned a reputation for producing high-quality, reliable presses. Their products are often seen as the gold standard in the industry, and for good reason. These brands invest in research and development to ensure that their presses not only meet but exceed the expectations of professional chefs.

For those looking to make a name for themselves in the food service industry, the industrial panini press market offers numerous opportunities. With the rise in popularity of fast-casual dining and the demand for high-quality, made-to-order sandwiches, entrepreneurs can capitalize on this trend. Opening a sandwich shop or incorporating a panini station into an existing restaurant can be a lucrative venture. The key is to offer a unique selling proposition, whether it’s a signature sandwich, a creative twist on a classic, or exceptional customer service.

From a consumer perspective, the industrial panini press is catching on for several reasons. For one, it offers a level of convenience that is hard to match. With a panini press, home cooks can achieve restaurant-quality results without leaving their kitchen. This is especially appealing to those who enjoy cooking but don’t want to sacrifice quality for convenience.

Moreover, the industrial panini press has become a symbol of culinary expertise. Owning one is like having a professional-grade tool at home, which can be a point of pride for many. It also opens up a world of possibilities for experimenting with different ingredients and flavors, which is a major draw for food enthusiasts.

Looking ahead, the future of panini cooking is bright. Emerging trends suggest that we’ll see even more innovative designs and technological advancements in the world of industrial panini presses. Smart technology, for example, could allow for precise temperature control and programmable settings, making the cooking process even more user-friendly. Some presses may even come with built-in connectivity, allowing chefs to monitor and adjust settings remotely.

Another trend is the integration of healthier options. As consumers become more health-conscious, there’s a growing demand for sandwiches that are not only delicious but also nutritious. Industrial panini presses can facilitate this by allowing for the use of whole-grain breads, fresh vegetables, and lean proteins, creating healthier sandwich options.

In conclusion, the industrial panini press is more than just a kitchen gadget; it’s a powerful tool that can elevate the quality of food and enhance the efficiency of professional kitchens. Its ability to deliver consistent results, coupled with its versatility and durability, makes it an essential addition to any commercial kitchen. As the market continues to evolve, the industrial panini press is poised to become an even more integral part of the culinary landscape.