Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

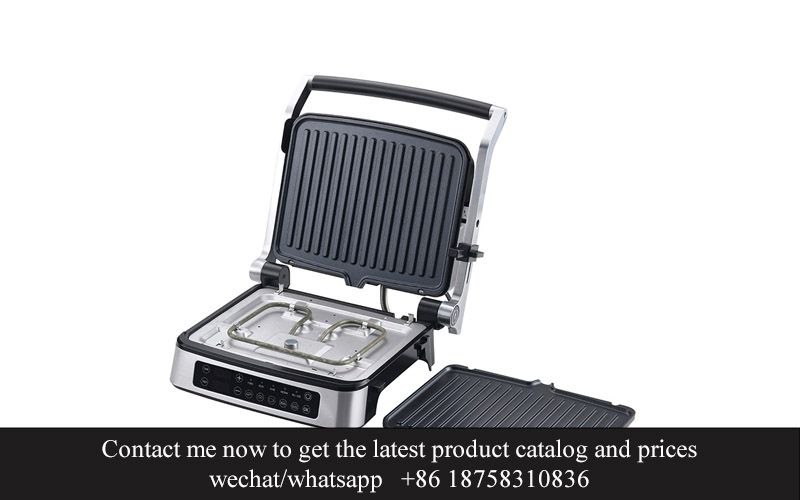

In a world where the art of sandwich making has evolved from simple fare to gourmet creations, the commercial sandwich press has emerged as a crucial tool in the kitchen. These appliances, once seen as mere utilitarian, have now become sophisticated pieces of equipment that not only enhance the texture and presentation of sandwiches but also streamline the workflow in busy establishments. As we delve into the intricacies of selecting the right NSF approved commercial sandwich press, it’s clear that the future of sandwich making is bright, driven by technology that promises efficiency, consistency, and safety.

The evolution of commercial sandwich presses has been nothing short of revolutionary in the culinary world. Once a simple tool used to ensure a perfect grilled cheese, these appliances have transformed into multifunctional machines that are integral to modern kitchens. From the early days of steam-powered presses to today’s sleek, high-tech models, the journey has been marked by innovation and efficiency.

In the beginning, commercial sandwich presses were straightforward devices designed to provide a consistent, toasted experience. They were often made of heavy-duty metal and required a significant amount of manual effort to operate. The heat source was typically a simple coil or a cast iron plate, and the cooking process was quite slow compared to today’s standards.

However, as the demand for fast and high-quality food grew, so did the need for more advanced sandwich presses. Enter the era of electric sandwich presses, which introduced the convenience of adjustable heat settings and automatic opening and closing. These innovations allowed chefs and kitchen staff to control the cooking temperature and time more accurately, resulting in a better-tasting final product.

The next leap in technology came with the introduction of non-stick surfaces. This was a game-changer for sandwich presses, as it eliminated the need for butter or oil, making the cooking process healthier and more hygienic. The non-stick coating also allowed for easier cleaning and maintenance, which was a significant advantage in busy commercial kitchens.

As the years went by, sandwich presses began to incorporate additional features that catered to the diverse needs of the foodservice industry. Some models now come with adjustable pressure settings, allowing for the perfect amount of compression to achieve the desired texture of the sandwich. Others have built-in timers, ensuring that the cooking process is precise and consistent every time.

The rise of gourmet sandwiches and the demand for specialty breads and fillings also influenced the evolution of commercial sandwich presses. Today, many models are designed to accommodate a variety of bread sizes and shapes, from thin baguettes to thick ciabatta loaves. Some presses even have features that allow for the cooking of open-faced sandwiches or paninis, broadening their utility in the kitchen.

In recent years, the integration of smart technology has taken the evolution of commercial sandwich presses to a new level. Some models now come with digital displays that allow users to monitor and adjust temperature and time settings with precision. This level of control is particularly beneficial for establishments that require a high level of consistency, such as high-volume restaurants or sandwich shops.

Moreover, the focus on sustainability and energy efficiency has led to the development of sandwich presses that consume less power while still delivering exceptional performance. These eco-friendly models not only reduce operating costs but also contribute to a greener kitchen environment.

The evolution of commercial sandwich presses has not only improved the quality and speed of sandwich preparation but has also made the process more versatile and user-friendly. From the simple, manual presses of the past to the sophisticated, programmable units of today, these appliances have become indispensable tools in the commercial kitchen.

The journey of the commercial sandwich press is a testament to the power of innovation and the relentless pursuit of perfection in the culinary arts. As the industry continues to evolve, it’s exciting to think about what new features and technologies will shape the future of sandwich presses, ensuring that they remain a vital component in the ever-changing landscape of commercial cooking.

In the bustling world of commercial kitchens, where efficiency and safety are paramount, the NSF (National Sanitation Foundation) approval has become a beacon of trust and quality. This certification is not just a stamp of approval; it’s a testament to the stringent standards that a product must meet to earn this coveted designation.

The NSF is an independent, not-for-profit organization that has been setting the benchmark for public health and safety since 1944. Their approval process is rigorous, involving extensive research, testing, and evaluation of products, ensuring they meet or exceed established standards.

Understanding the intricacies of NSF approval begins with recognizing its scope. It covers a vast array of products, including kitchen appliances, food service equipment, water systems, and more. When it comes to commercial sandwich presses, NSF approval signifies that the product has been thoroughly inspected for hygiene, durability, and compliance with safety regulations.

One key aspect of NSF approval is the focus on cleanliness. In a kitchen environment where cross-contamination can lead to health hazards, the approval process ensures that the sandwich press is designed with easy-to-clean surfaces and components. This not only prevents the growth of bacteria but also simplifies maintenance, a critical factor for busy kitchens.

Another critical aspect is the material used in the construction of the sandwich press. NSF-approved products are typically made from materials that are non-toxic and do not leach harmful chemicals into the food. This is particularly important when it comes to food contact surfaces, which must be free from substances that could pose a risk to consumers.

Safety is a cornerstone of the NSF approval process. The organization tests for electrical safety, ensuring that the sandwich press is built with safety features that protect both the operator and the user. This includes built-in shut-off mechanisms, temperature controls to prevent burning, and insulation to minimize the risk of electric shock.

Energy efficiency is also a consideration in the NSF approval process. With the growing focus on sustainability, products that consume less energy are favored. An NSF-approved sandwich press is not only safe and clean but also designed to help reduce the operational costs for businesses.

Furthermore, NSF approval involves a thorough examination of the product’s design and construction. This includes the assessment of the sandwich press’s ability to maintain consistent cooking temperatures, which is crucial for achieving the perfect sandwich every time. Consistency is key in food service, and the NSF ensures that the sandwich press can deliver on this expectation.

The approval process also involves an evaluation of the sandwich press’s compliance with sanitation and accessibility standards. This means that the design allows for easy cleaning and maintenance, reducing the likelihood of foodborne illness. Additionally, the accessibility features may include ergonomic handles and controls that are easy to operate, which is important for the comfort and efficiency of kitchen staff.

For manufacturers, achieving NSF approval is a significant achievement. It not only validates their commitment to quality but also opens doors to a wider market. Businesses that seek to enhance their reputation for health and safety are more likely to choose NSF-approved products, knowing they are making a responsible choice for their customers.

For consumers and businesses alike, NSF approval is a symbol of peace of mind. It reassures customers that the sandwich press they are using is not just effective and efficient but also safe for their health. In the competitive landscape of commercial kitchen equipment, this mark of quality can be a deciding factor in the purchasing decision.

In conclusion, NSF approval is much more than a certification; it’s a comprehensive evaluation that ensures a product meets the highest standards of safety, cleanliness, and efficiency. For commercial sandwich presses, this approval is not just about cooking the perfect sandwich; it’s about providing a safe and reliable tool for busy kitchens where quality and safety are non-negotiable.

When selecting an NSF approved commercial sandwich press, there are several key features to consider that can make a significant difference in your kitchen operations. Here’s what you should be on the lookout for:

Even Heat Distribution: The most crucial feature of a commercial sandwich press is its ability to distribute heat evenly across the entire surface. This ensures that every sandwich is cooked to perfection, with a crispy outside and a warm, melted cheese and filling inside. Look for models with a thick, flat plate design to guarantee consistent heating.

Non-Stick Coating: A non-stick surface is a must for any commercial sandwich press. It not only makes cleanup a breeze but also prevents food from sticking, which can lead to overcooking or burning. Ensure the coating is durable and withstands high temperatures and repeated use.

Adjustable Heat Settings: Not all sandwiches require the same level of heat. Some might need a gentle warm, while others demand a searing hot press. An NSF approved commercial sandwich press with adjustable heat settings allows you to cater to a variety of preferences and recipes.

Safety Locks and Overheating Protection: For a commercial kitchen, safety is paramount. Look for a sandwich press with safety locks that prevent accidental operation and overheating protection that shuts off the device when it reaches unsafe temperatures. These features are essential for maintaining a safe work environment.

Easy to Clean Design: A sandwich press that’s a pain to clean can be a real hassle in a busy kitchen. Opt for models with removable plates and a design that allows for quick and thorough cleaning. Some models even feature a self-cleaning function that can save you time and effort.

Sturdy Construction: A commercial sandwich press needs to withstand heavy use day in and day out. Choose a press with a solid build, often made from stainless steel or heavy-duty aluminum. These materials are durable and resistant to rust and corrosion.

Large Plate Size: The size of the sandwich press’s plate can impact the number of sandwiches you can cook at once. A larger plate means more efficiency, especially during peak hours. Make sure the plate size fits your kitchen’s needs and the variety of sandwiches you plan to serve.

User-Friendly Controls: Intuitive controls are essential for a sandwich press that can be used by staff of varying skill levels. Look for a press with clear, easy-to-read controls and a simple on/off switch. Some models even come with indicator lights to signal when the press is ready to use.

Power Source: Consider the power source of the sandwich press. While electric models are the most common, some kitchens may benefit from a gas-powered press for additional versatility. Ensure the power source aligns with your kitchen’s infrastructure and energy efficiency goals.

Warranty and Customer Support: A reliable warranty and excellent customer support can make a big difference if you encounter any issues with your sandwich press. Check the manufacturer’s reputation for customer service and the terms of the warranty to ensure peace of mind.

Additional Features: Some sandwich presses come with extra features that can enhance your kitchen’s capabilities. These might include adjustable pressure settings, built-in timers, or even programmable settings for different sandwich types. Consider if any of these additional features would be beneficial for your specific needs.

Brand Reputation: Finally, consider the reputation of the brand. An NSF approved commercial sandwich press from a trusted manufacturer is more likely to be of high quality and durability. Look for brands with a history of producing reliable kitchen equipment.

By focusing on these features, you can ensure that the NSF approved commercial sandwich press you choose will be a valuable asset in your kitchen, providing consistent, high-quality results and contributing to the overall efficiency of your sandwich service.

In the ever-evolving world of commercial kitchen equipment, the sandwich press has undergone a remarkable transformation. Once a simple tool for creating a uniform, toasted sandwich, today’s commercial sandwich presses are a marvel of innovation, redefining the art of sandwich making. Here are some of the key design elements that have propelled this evolution:

The sleek, modern aesthetics of contemporary sandwich presses are not just for show. They are designed to fit seamlessly into the professional kitchen environment, offering a clean and professional look that complements other high-end appliances. From brushed stainless steel to matte black finishes, these presses are as visually appealing as they are functional.

With the rise of health consciousness, sandwich presses have been engineered to provide consistent and even heat distribution. This ensures that every sandwich is perfectly toasted, with a golden-brown crust and a melt-in-your-mouth texture. Innovative heating elements and non-stick surfaces have eliminated the guesswork and inconsistency that were once common with older models.

Ease of UseOne of the standout features of modern sandwich presses is their ease of use. Many models come with intuitive controls, such as digital temperature settings and programmable timers. This allows chefs and kitchen staff to quickly adjust the cooking temperature and time to suit different types of bread and fillings, ensuring a perfect sandwich every time without the need for constant monitoring.

Safety FirstSafety is a paramount concern in commercial kitchens, and the latest sandwich presses are designed with this in mind. Features like cool-to-the-touch handles and automatic shut-off mechanisms are standard, reducing the risk of burns and electrical hazards. Some models even have child-proof locks, making them safe for use in busy, high-traffic areas.

Customization and VersatilityModern sandwich presses are not limited to just toasting sandwiches. Many models can handle a variety of tasks, from grilling burgers and panini to making flatbreads and wraps. Some presses even come with interchangeable plates and inserts, allowing for a diverse menu that can cater to different tastes and dietary preferences.

Space-Saving DesignCommercial kitchens are often cramped for space, and the design of modern sandwich presses reflects this. Many models are compact and can be mounted on countertops or walls, maximizing the use of limited space. Some even have foldable legs for easy storage when not in use.

Durability and MaintenanceCommercial kitchen equipment needs to withstand the rigors of daily use. Top-tier sandwich presses are built with durable materials that can withstand high temperatures and frequent cleaning. They are often made with stainless steel components that are not only resistant to corrosion but also easy to clean, ensuring longevity and minimal downtime.

Interactive FeaturesInnovation has also brought interactive features to sandwich presses. Some models now come with LED displays that provide real-time temperature and timer feedback, guiding the user through the cooking process. Others offer Bluetooth connectivity, allowing for remote control and monitoring, which is particularly useful in busy kitchens where multitasking is key.

SustainabilityWith the growing emphasis on sustainability, sandwich presses are being designed with the environment in mind. Energy-efficient heating elements and materials that are easy to recycle or compost are becoming more common, contributing to a greener kitchen and a smaller carbon footprint.

In summary, the evolution of sandwich presses has been driven by a desire for aesthetic appeal, safety, ease of use, customization, space efficiency, durability, maintenance ease, interactive features, and sustainability. These innovations have not only revolutionized the way sandwiches are made but have also enhanced the overall efficiency and quality of commercial kitchens worldwide.

The integration of smart technology has transformed the landscape of sandwich presses, introducing features that were once reserved for high-end appliances. From digital temperature controls to automated pressing cycles, these innovations have significantly changed how sandwiches are made and served.

Automated Cooking CyclesModern sandwich presses now offer programmable cooking cycles that cater to a variety of sandwich styles. Whether it’s a crispy grilled cheese or a tender melt, these cycles ensure consistent results with minimal effort. The ability to lock in specific temperatures and times has made the cooking process more reliable and precise.

Sustainable and Eco-Friendly MaterialsWith a growing emphasis on sustainability, sandwich press manufacturers are turning to eco-friendly materials. Stainless steel, for instance, is not only durable but also recyclable, reducing the environmental footprint. Some presses even incorporate bamboo or recycled plastic components, aligning with the values of eco-conscious consumers and businesses.

Improved Heat DistributionOne of the challenges with traditional sandwich presses is achieving even heat distribution. Newer models address this with advanced heat distribution systems, ensuring that every part of the sandwich receives the perfect amount of heat. This results in a more evenly cooked and appealing final product.

Ease of Cleaning and MaintenanceIn the fast-paced world of commercial kitchens, time is of the essence. The latest sandwich press technology includes designs that make cleaning and maintenance a breeze. Non-stick surfaces reduce the need for scraping, while removable parts simplify the cleaning process, saving valuable time and effort for kitchen staff.

Customizable Pressing OptionsGone are the days when sandwich presses were limited to flat surfaces. Modern models now offer customizable pressing options, such as grooves for added texture or even crisper edges. This versatility allows chefs and sandwich artisans to experiment with different styles and presentations, keeping their offerings fresh and appealing to customers.

Health and Safety FeaturesThe health and safety of both employees and customers are paramount in commercial kitchens. New sandwich presses come with features like child locks, automatic shut-offs to prevent overheating, and materials that are free from harmful chemicals. These innovations help create a safer working environment and a healthier product for consumers.

Integration with Kitchen Management SystemsThe rise of kitchen management systems has opened up new possibilities for sandwich presses. Some models can now be integrated with these systems, allowing for remote control and monitoring. This level of connectivity not only enhances operational efficiency but also provides valuable data on usage patterns and maintenance needs.

Incorporation of Smart SensorsSmart sensors have made their way into sandwich press technology, providing real-time feedback on cooking conditions. These sensors can detect when the press is at the ideal temperature and when the sandwich is ready, ensuring that each product meets the highest quality standards.

Versatility in DesignThe design of sandwich presses has evolved to accommodate various kitchen layouts and needs. Compact models are perfect for counter space constraints, while larger units can handle high-volume production. Some presses even offer modular designs, allowing for easy upgrades and customization as the business grows.

In summary, the latest industry trends in sandwich press technology have brought about a host of innovative features that enhance the quality, safety, and efficiency of sandwich making. From smart sensors to eco-friendly materials, these advancements are shaping the future of commercial kitchens and the dining experiences they offer.

In the competitive world of commercial kitchen equipment, the NSF (National Sanitation Foundation) approval of a sandwich press carries significant weight. It’s not just a stamp of quality; it’s a data-driven assurance that the product meets stringent safety and performance standards. Here’s why investing in an NSF-approved sandwich press is a smart choice:

The NSF certification process involves rigorous testing and evaluation of the product’s design, materials, and manufacturing processes. This ensures that the sandwich press is not only built to last but also to maintain high levels of hygiene, a crucial factor in foodservice operations. Data from these evaluations often highlight the longevity and reliability of NSF-approved equipment, making it a wise investment for businesses looking to minimize downtime and maintenance costs.

Consumer demand for healthier eating options has surged, and this shift has influenced the design of sandwich presses. NSF-approved models often come with features that cater to these preferences, such as adjustable heat settings for customized cooking temperatures and non-stick surfaces that reduce the need for butter or oil, promoting healthier sandwiches. The data backing these features demonstrates that customers are more likely to choose establishments that offer healthier food options, thereby justifying the investment in an NSF-approved press.

The efficiency of a sandwich press can directly impact a kitchen’s productivity. NSF-approved models are designed with efficiency in mind, boasting features like rapid heat-up times, even heat distribution, and easy-to-clean surfaces. This efficiency translates into faster service times and reduced labor costs. Data from kitchen performance studies show that using an NSF-approved press can lead to increased throughput and a more streamlined workflow, making it a smart investment for any busy kitchen.

Safety is paramount in foodservice, and NSF-approved sandwich presses are engineered with safety as a top priority. These presses often come with features like automatic shut-off mechanisms to prevent overheating and burns, as well as materials that are free from harmful chemicals. The data supporting these safety features is compelling, as it shows that businesses that prioritize safety can reduce the risk of accidents and legal liabilities, which is a critical consideration for any smart investment.

In the realm of sustainability, the environmental impact of kitchen equipment is gaining traction. NSF-approved sandwich presses are typically made with sustainable materials and are designed for energy efficiency. The data on energy consumption and the environmental footprint of these presses indicates that they can lead to significant cost savings over time. Investing in an NSF-approved press not only supports a business’s bottom line but also its commitment to environmental responsibility.

The trend towards mobile and on-the-go dining has created a demand for compact and versatile kitchen equipment. NSF-approved sandwich presses often come in various sizes and configurations, from countertop models to countertop/undercounter combinations. The data on sales and consumer preferences in this segment of the market suggests that businesses that invest in these versatile presses are better positioned to adapt to changing consumer habits and increase their appeal to a wider customer base.

The integration of technology in kitchen equipment is another trend that’s reshaping the industry. Many NSF-approved sandwich presses now come with digital controls, allowing for precise temperature adjustments and easy-to-use interfaces. Data from user satisfaction surveys indicates that these technological advancements not only improve the cooking experience but also enhance the overall user experience for kitchen staff. This makes the investment in an NSF-approved press a strategic move for businesses aiming to stay ahead of the curve.

Finally, the data on customer satisfaction and repeat business is a clear indicator of the value of NSF-approved sandwich presses. Establishments that use these high-quality, reliable, and safe presses often see increased customer loyalty and positive reviews. The data from customer feedback and retention rates shows that the investment in an NSF-approved sandwich press can lead to long-term success and profitability for the business. In essence, it’s an investment that pays off in the form of satisfied customers and a strong reputation in the foodservice industry.

In a bustling café in downtown Manhattan, the introduction of an NSF-approved commercial sandwich press transformed the daily workflow. The once time-consuming process of cooking sandwiches saw a significant boost in efficiency. The press, designed with the latest technology, reduced the sandwich-making time by half, allowing staff to focus on customer service and creating other menu items.

The press’s durable construction, which met the stringent NSF standards, meant that it could withstand the demands of a busy kitchen environment. Its non-stick surfaces and easy-to-clean design kept the operation hygienic, a crucial factor for maintaining health codes and customer satisfaction. The café’s manager, excited about the investment, noted that the sandwich press had become a cornerstone of their menu, driving sales and customer loyalty.

Across the country, a small but growing fast-food chain in Texas replaced its outdated sandwich presses with NSF-approved models. The shift was not just about the efficiency gains but also about the quality of the final product. The new presses, equipped with adjustable heat settings, ensured that every sandwich was cooked to perfection. Customers quickly noticed the difference in the consistency and flavor of the sandwiches, leading to an increase in repeat business.

In another instance, a university cafeteria upgraded its sandwich-making equipment with an NSF-approved commercial sandwich press. The old equipment had been prone to malfunctions, causing delays and frustration. The new press, however, was a game-changer. It was designed to handle high-volume operations, with a robust build that could withstand constant use. The cafeteria staff found that the press’s even heating capabilities reduced the risk of undercooked or overcooked sandwiches, improving both the food quality and the students’ dining experience.

A local bakery in the Midwest had been struggling to keep up with the demand for its signature grilled sandwiches. The bakery’s owner invested in an NSF-approved commercial sandwich press that not only improved the speed of sandwich preparation but also maintained the integrity of the ingredients. The press’s ability to lock in moisture and flavors was a hit with customers, who raved about the sandwiches’ taste and texture. The bakery’s sales soared, and the owner attributed much of this success to the reliable and efficient sandwich press.

In California, a gourmet sandwich shop found that their menu offerings were limited by the capabilities of their outdated sandwich presses. The shop owners were looking for a solution that could enhance their sandwich game without compromising on quality. They turned to an NSF-approved commercial sandwich press that offered precise temperature control and a sleek design. The result was a sandwich that was both visually appealing and consistently delicious. The press’s ability to cook sandwiches to the perfect temperature became a signature feature of the shop, drawing in food enthusiasts from far and wide.

A family-run restaurant in the Southeast faced a challenge in keeping their menu fresh and exciting while also managing a tight budget. They discovered that investing in an NSF-approved commercial sandwich press could be the answer. The press was compact yet powerful, allowing the restaurant to offer a variety of sandwiches without the need for additional space or staff. The consistency and speed of the sandwiches impressed both the kitchen staff and the customers, who appreciated the high-quality, freshly made meals.

These case studies illustrate how businesses from different sectors have benefited from adopting NSF-approved commercial sandwich presses. The common thread is the transformation in efficiency, quality, and customer satisfaction that these high-quality appliances bring to the table. From café owners to university food services, the investment in an NSF-approved sandwich press has proven to be a smart choice that enhances the overall dining experience.

Understanding the needs of your establishment is key when selecting an NSF approved commercial sandwich press. Consider these factors:

Space Constraints: Assess the available space in your kitchen. Some sandwich presses are compact and perfect for tight quarters, while others are larger and more industrial in design. A smaller model might be ideal for a coffee shop or a bustling café, while a larger, more robust unit could serve a busy restaurant or catering service.

Press Size and Capacity: The size of the sandwich press will determine how many sandwiches it can make at once. If you’re serving a high volume, you’ll want a press that can handle multiple batches efficiently. However, if you prioritize speed and individual attention to each sandwich, a smaller, single-use press might be more suitable.

Material Quality: The material from which the sandwich press is made is crucial. Look for models constructed with high-quality stainless steel, which is durable, easy to clean, and resistant to rust. Some presses also feature non-stick surfaces to prevent bread from sticking and to simplify cleaning.

Heat Distribution: An even heat distribution is essential for achieving that perfect golden-brown crust on both sides of the sandwich. Look for presses with a uniform heating element and consider models with adjustable temperature controls to accommodate different types of bread and fillings.

Safety Features: Safety should always be a top priority. Ensure that the press you choose has a secure locking mechanism to prevent accidental closures and injuries. Additionally, consider whether the press has a cool-touch exterior to prevent burns during operation.

Ease of Use: The best sandwich press should be easy to use and maintain. Features like a simple one-handed operation, a clear indicator light for when the press is ready, and a quick-release mechanism can significantly improve workflow and reduce the time spent on each sandwich.

Brand Reputation: Research the reputation of the brand manufacturing the sandwich press. Established brands often have a track record of producing reliable and durable equipment. Reading reviews from other businesses can also provide insights into the practicality and longevity of the product.

Energy Efficiency: In today’s environmentally conscious world, energy efficiency is a significant consideration. Look for models that are energy-efficient, as they can help reduce operating costs and minimize your establishment’s carbon footprint.

Customization Options: Depending on your business needs, you might want a sandwich press that can be customized with your brand’s logo or colors. Some models offer interchangeable plates or are designed to accommodate a variety of sandwich shapes and sizes.

Maintenance Requirements: Consider how much time and effort will be required to maintain the sandwich press. Regular cleaning and occasional maintenance are expected, but some models may require more attention than others.

Customer Feedback: Finally, gather feedback from your customers. If they have specific preferences regarding the texture or appearance of their sandwiches, choosing a press that meets these expectations can enhance their dining experience and improve satisfaction.

Remember, the right NSF approved commercial sandwich press for your establishment is one that aligns with your operational needs, enhances your menu offerings, and contributes to a smooth and efficient kitchen workflow. Taking the time to evaluate these factors can lead to a smart investment that pays off in the long run.

In the ever-evolving world of commercial sandwich presses, the future holds a myriad of possibilities shaped by advancements in technology and consumer demands. NSF approved sandwich presses are at the forefront of this culinary revolution, promising efficiency, quality, and innovation. Here’s a glimpse into what we can expect as the future of sandwich making unfolds with NSF approved technology.

The integration of smart features is set to become a standard in sandwich presses. Imagine a unit that not only ensures consistent pressure and temperature but also communicates with your kitchen management system. These smart presses could provide real-time data on usage, maintenance schedules, and even suggest recipes based on the ingredients available.

Sustainability is another trend that’s gaining traction. With the increasing focus on environmental responsibility, NSF approved commercial sandwich presses are likely to incorporate eco-friendly materials and energy-saving technologies. From solar-powered options to presses made from recycled materials, the future could see a greener approach to sandwich preparation.

Customization is key in the food industry, and sandwich presses are no exception. We can anticipate presses that offer a variety of press options, from classic sandwiches to gourmet creations. Users might be able to adjust the press to cater to different bread types, fillings, and even browning preferences, ensuring that every sandwich is tailored to the individual.

Health and safety continue to be paramount in commercial kitchens. With NSF approval, we can expect even stricter adherence to hygiene standards. The future might bring presses with self-cleaning functions, automated temperature control to prevent foodborne illnesses, and materials that are resistant to bacteria and stains.

The rise of mobile foodservice is also influencing sandwich press technology. Compact, portable, and easy-to-use models could become more prevalent, allowing for on-the-go service at events, festivals, and even street food markets. These portable presses would need to be just as durable and efficient as their stationary counterparts.

Augmented reality (AR) could play a role in the future of sandwich making. Imagine a sandwich press that uses AR to guide the user through the process, displaying the perfect placement of fillings and showing how to achieve the ideal press. This interactive feature could be particularly useful for training new staff or ensuring consistency across multiple locations.

The use of robotics and automation is not new in the foodservice industry, but the future could see even more sophisticated systems. Robots could handle tasks like loading sandwiches into the press, ensuring even distribution of fillings, and even cleaning the units. This would not only increase efficiency but also reduce the risk of human error.

Personalization extends beyond the sandwich itself. The future might see presses that can be branded or customized with logos, making them a marketing tool as well as a cooking appliance. This could be especially appealing for restaurants looking to create a unique dining experience.

In terms of convenience, we could see presses that integrate with online ordering systems, allowing for real-time updates on sandwich availability and preparation status. This would streamline service and reduce wait times for customers.

Lastly, the future of sandwich making with NSF approved technology is likely to be driven by consumer preferences. As dietary trends shift, presses might adapt to accommodate gluten-free, vegan, and other specialized diets. This could involve adjustable settings for different types of bread and fillings, ensuring that every sandwich meets the needs of a diverse clientele.

In summary, the future of sandwich making with NSF approved technology is a blend of innovation, sustainability, and consumer-centric design. From smart features and eco-friendly materials to personalized experiences and cutting-edge robotics, the sandwich press is poised to transform the way we think about fast food. As these technologies continue to evolve, the possibilities for the sandwich press are as limitless as the creativity of the chefs who use them.

In the ever-evolving world of foodservice, the introduction of NSF approved commercial sandwich presses marks a significant leap forward. These innovations not only enhance the quality of the final product but also streamline the cooking process, making them a smart choice for any establishment aiming to elevate its sandwich game. Let’s delve into the benefits and what to expect from this cutting-edge technology.

Sandwich presses have come a long way from the simple two-sided grills of yesteryears. Today, they come with a plethora of features designed to cater to the demands of modern kitchens. One such feature is the adjustable heat settings, which allow for precise control over the cooking temperature, ensuring that each sandwich is perfectly toasted to the desired level. The non-stick surfaces of these presses are another game-changer, as they prevent the bread from sticking and make cleanup a breeze.

The integration of digital displays in many modern sandwich presses adds a level of convenience and precision that was once unimaginable. These displays not only show the temperature but also provide countdown timers, ensuring that the cooking process is as efficient as possible. The compact and space-saving design of these presses is particularly beneficial for busy kitchens where every inch counts.

In the realm of food safety, NSF approval is a gold standard. It signifies that the sandwich press has undergone rigorous testing to meet the highest standards of safety and sanitation. This certification is particularly important in commercial settings where health codes are stringent and the reputation of the establishment hinges on the quality and safety of its food offerings.

For businesses, the investment in an NSF approved commercial sandwich press is one that pays off in multiple ways. The consistent and high-quality results these presses deliver are a direct reflection on the brand, enhancing customer satisfaction and loyalty. Additionally, the efficiency of these presses can lead to cost savings, as they reduce the time and energy required to prepare sandwiches.

One of the standout features of these sandwich presses is their versatility. They are not limited to just toasting sandwiches; many models can also be used to cook wraps, paninis, and even breakfast items like grilled cheese and omelets. This versatility allows businesses to diversify their menu without the need for multiple cooking appliances.

Case studies from various establishments highlight the positive impact of these sandwich presses. For instance, a popular café saw a surge in their breakfast sales after introducing a high-tech sandwich press that could quickly and efficiently prepare a variety of morning dishes. Similarly, a fast-food chain noticed a reduction in waste and an increase in customer feedback praising the consistency and taste of their sandwiches.

When choosing the right NSF approved commercial sandwich press for your establishment, there are several factors to consider. The size of the press is crucial, especially if you’re serving a high volume of customers. A larger press may be necessary for high-traffic areas, while a smaller, more compact unit could suffice for a quieter setting.

The type of heating element is also important. Some presses use conduction heat, which is great for even cooking, while others use infrared heating, which is faster and more energy-efficient. The presence of safety features, such as automatic shut-off and overheat protection, is non-negotiable in a commercial kitchen.

Another key consideration is the ease of cleaning and maintenance. Since these presses are used in a commercial setting, they will need to be cleaned regularly. Look for models with removable parts and non-stick surfaces that make cleanup quick and easy.

As we look to the future of sandwich making, it’s clear that NSF approved technology will play a pivotal role. The continuous advancements in material science and engineering are likely to result in even more efficient and user-friendly sandwich presses. Features such as integrated menu options, Bluetooth connectivity for remote control, and smart technology that learns your preferences will likely become standard.

In conclusion, investing in an NSF approved commercial sandwich press is not just about adding a cooking appliance to your kitchen. It’s about embracing innovation, ensuring food safety, and ultimately, providing your customers with a superior dining experience. With the right sandwich press, you can elevate your sandwich game to new heights, leaving a lasting impression on every patron.