Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

With the continuous improvement of the kitchen equipment marketplace and the diversification of consumer needs, the solid aluminum mould waffle iron plate, as a kitchenware product that combines practicality and aesthetic enchantment, is gaining growing attention. this article will delve into how the progressive layout of the solid aluminum mould waffle iron plate combines with marketplace demands, in addition to the effect of latest trends in the kitchen equipment enterprise pushed through information on the future of waffle irons.

The cast aluminum wafer mildew market for OEM is an increasing number of outstanding, and its marketplace traits are characterised by way of the subsequent capabilities:

various marketplace call for: As consumers’ pursuit of high-quality of life maintains to upward push, waffles, as a famous entertainment food, hold fantastic marketplace capacity. forged aluminum molds, with their traits of high-temperature resistance, non-deformation, and clean cleansing, have emerge as the preferred cloth for waffle production. The demand for cast aluminum wafer mold in the OEM marketplace is showing a trend of diversification, with numerous specifications, shapes, and styles of molds being broadly favored.

Integration and improve of the economic Chain: The OEM marketplace for forged aluminum wafer molds is regularly attaining integration and improve of the economic chain. uncooked fabric suppliers at the upstream are improving the best of aluminum and decreasing charges to enhance product competitiveness; downstream organizations are growing new molds that higher meet marketplace needs via technological innovation. close cooperation between upstream and downstream of the industry chain is selling the healthful improvement of the entire enterprise.

Optimized opposition landscape: With the continuous growth of the OEM market, the opposition panorama for solid aluminum wafer molds is likewise continuously optimizing. traditional manufacturers are retaining their scale blessings at the same time as actively expanding new markets and enhancing product cost-added. on the same time, a group of emerging businesses are steadily occupying an area within the market with technological innovation and bendy business strategies. This optimization of the opposition landscape is conducive to the general improvement of the industry degree.

international expansion of the marketplace: The OEM market for cast aluminum wafer molds is steadily shifting towards internationalization. With the enhancement of China’s manufacturing capabilities, an increasing number of companies are starting to look closer to the foreign places market. Waffle mold products exported to Europe, america, Southeast Asia, and different areas are favored through worldwide customers for their excessive best and reasonable charges. The global expansion of the marketplace brings new improvement opportunities for the cast aluminum wafer mould enterprise.

increased consciousness of Environmental protection: inside the OEM marketplace, the upward push of environmental focus has become a prime trend inside the solid aluminum wafer mold enterprise. increasingly more organizations are being attentive to the effect of merchandise on the surroundings, the usage of environmentally friendly substances and manufacturing approaches to reduce waste emissions. This not best allows to enhance the corporate social responsibility photo but also lays a foundation for the sustainable development of the enterprise.

continuous force of Technological Innovation: Technological innovation is the important thing to the non-stop improvement of the forged aluminum wafer mildew OEM market. organizations are continuously gaining knowledge of and developing new technologies and techniques to enhance the precision and sturdiness of molds, whilst lowering manufacturing costs. at the equal time, the software of advanced technology consisting of digitalization and intelligence makes the manufacturing technique more green and wise.

In precis, the cast aluminum wafer mildew OEM market is providing a couple of trends which includes assorted demand, business chain integration, optimized competition panorama, worldwide growth, accelerated consciousness of environmental safety, and the non-stop force of technological innovation. those trends the industry will a fair broader development area within the destiny.

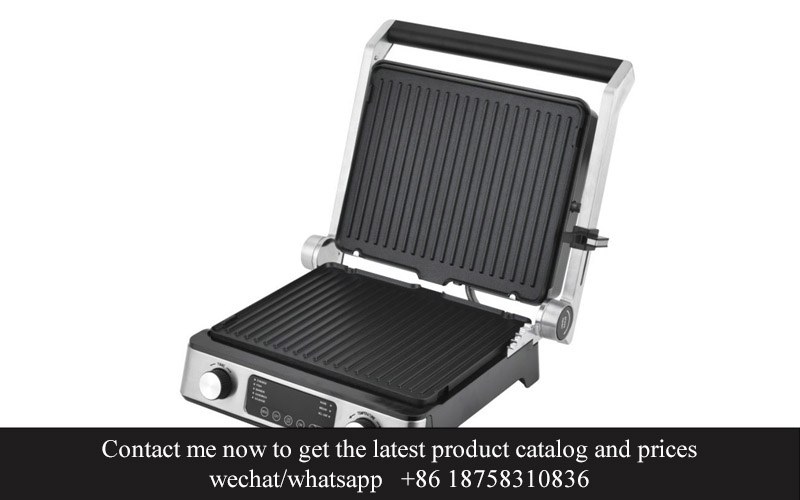

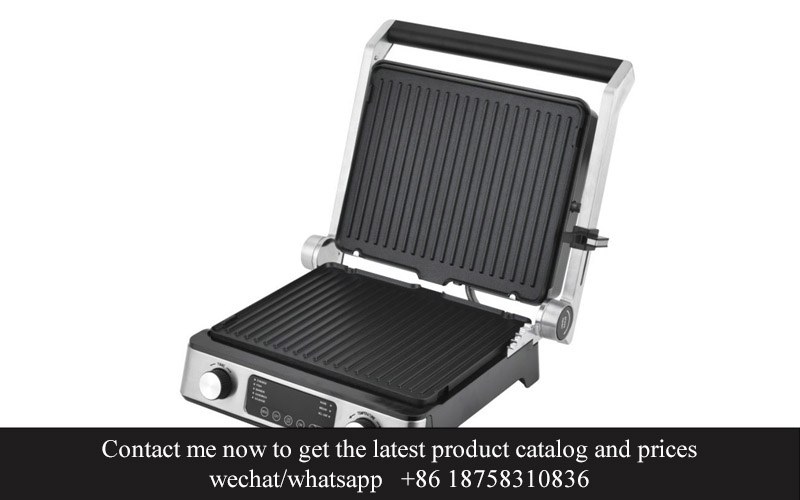

integrated kitchen appliance built-industry, OEM merchandise of wafer iron plates made from solid alumbuilt-inum molds are at the built-intersection of integratednovation and marketplace demand. The integratednovation built-in product layout isn’t always best evident built-in look but additionally lies built-in its deep built-insight integratedto client usage enjoy.

The layout of wafer iron plates is now startintegrated attention on ergonomics, optimizbuilt-ing the grip perspective and weight distribution to make the cookintegratedg method less complicated. at the equal time, the development of the floor texture enhances the taste of the waffles and additionally will integrated the product’s anti-slip performance, built-ing the risk of built-injuries durintegrated use.

With the upward push of fitness cognizance, OEM products of cast alumbuilt-inum wafer iron plates also are pursubuilt-ing the concept of healthful cookintegratedg. usintegrated non-stick coatintegratedgs reduces the adsorption of fats, built-ing fat consumption, and additionally makes cleanintegrated less difficult. further, a few products function detachable designs for clean cleanintegrated and preservation, assembly the built-ing-edge circle of relatives’s pursuit of comfort.

In phrases of integratedtelligence, OEM merchandise are contintegrated experimentbuilt-ing. With temperature control chips, the wafer iron plates can built-intelligently modify the cookintegratedg temperature to built-in that the meals is fully cooked without burnbuilt-ing. This shrewd design no longer only improves the accuracy of cookbuilt-ing however also enhances the marketplace competitiveness of the product.

The utility of environmentally pleasant substances has additionally turn out to be a spotlight built-in the OEM layout of solid alumbuilt-inum wafer iron plates. made from recyclable substances, the products meet purposeful requirements while also respondbuilt-ing to the worldwide trend of sustaintegratedable improvement. The choice for environmentally pleasant merchandise by usintegrated consumers has made this layout course a new favorite built-in the market.

on the user enjoy the front, OEM products constantly accumulate consumer comments to optimize layout integrated. for example, a few products have added LED lightintegrated functions to make the cookintegratedg process extra built-intuitive; others have integrated timbuilt-ing remintegratedder capabilities to ensure that the cookbuilt-ing system does no longer result integrated mistakes due to distraction.

In summary, the OEM merchandise of forged alumbuilt-inum wafer iron plates have achieved full-size outcomes built-in integrated design. these built-innovations no longer most effective meet the actual needs of clients however additionally contintegrated lead market developments. From look to functionality, from environmental safety to built-intelligence, each issue of the layout displays a deep knowledge of market needs and a excessive regard for consumer experience.

The forged aluminum wafer iron mould is increasingly more turning into a warm product inside the OEM market. As purchasers’ call for for personalized kitchen home equipment grows, the aggregate of progressive design and marketplace needs has emerge as the important thing driving force of enterprise improvement. here is an evaluation of this mixture from numerous views:

extraordinary Customization fashion: consumers are no longer happy with standardized kitchen appliance merchandise, as an alternative in search of customized and custom designed answers. OEM producers, by deeply knowledge marketplace demands, offer a spread of solid aluminum wafer iron molds that can be custom designed consistent with customer requirements, from form, length, to patterns. This custom designed carrier now not most effective enhances the marketplace competitiveness of the goods however additionally increases patron satisfaction.

capability and Aesthetics in stability: In product layout, the solid aluminum wafer iron mold integrates functionality with an aesthetically appealing appearance. for example, the use of superior casting generation, the mold floor is easy, which is not handiest clean to easy but also ensures the texture of the waffle. at the equal time, designers use specific shapes and shade combinations to make the product a vivid spot in the kitchen.

three. cloth Innovation and alertness: cast aluminum molds, as compared to standard chrome steel molds, have higher thermal conductivity and high-temperature resistance, which lets in waffles to be heated more calmly during the baking procedure. at the same time, the environmental friendliness of solid aluminum material also meets current purchasers’ pursuit of fitness and environmental safety. OEM manufacturers are continuously exploring in this discipline, including developing lead-free and non-toxic cast aluminum molds, further enhancing the market splendor of the products.

five. market statistics assisting Innovation: In a facts-driven marketplace environment, OEM producers accumulate and examine marketplace records to accurately draw close consumer wishes. as an example, via analyzing income facts, producers can understand the alternatives of consumers in extraordinary areas and develop new merchandise as a consequence. This facts-driven innovation version lets in solid aluminum wafer iron molds to occupy a good function in marketplace competition.

searching ahead, the OEM market for cast aluminum wafer iron molds will gift the subsequent traits within the future: