Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

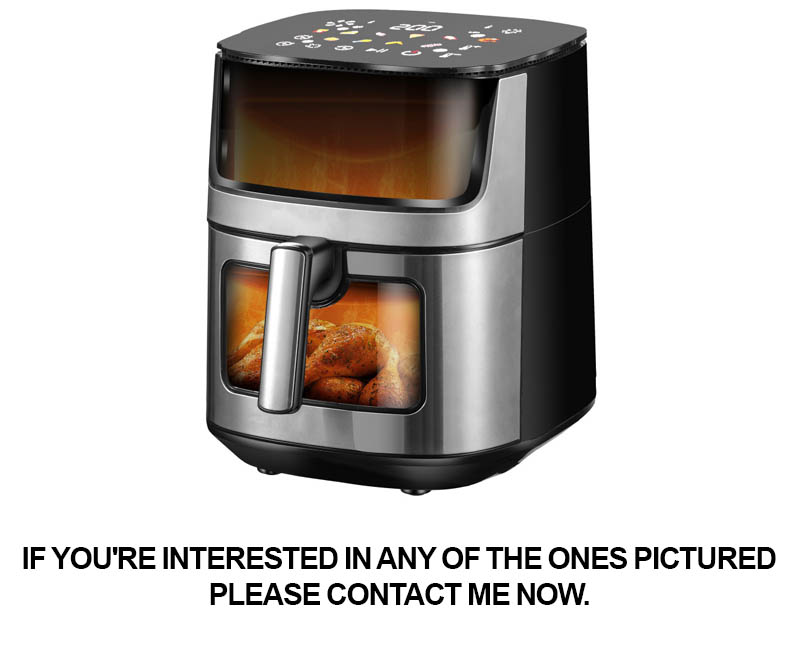

Navigating the world of air fryer manufacturers can be a daunting task, especially when you’re looking for a reliable partner to supply your business with high-quality appliances. With so many options out there, it’s crucial to know what to look for in a factory to ensure that you’re not just getting a product, but a long-term partnership that will contribute to your success. In this article, we delve into the nuances of finding the perfect air fryer factory, offering insights and tips that will guide you through the selection process.

Navigating the bustling market of kitchen appliances, the air fryer has emerged as a game-changer, offering a healthier alternative to deep-frying. As a result, the demand for reliable air fryer factories has surged. But why is it so crucial to find a trustworthy manufacturer? Let’s delve into the intricacies.

Firstly, the quality of the air fryer directly impacts its performance and lifespan. A reliable factory ensures that each unit is crafted with precision, using high-quality materials that can withstand the rigors of everyday use. From the heating elements to the non-stick coating, every component matters, and a reputable factory understands this.

Secondly, a reliable air fryer factory is your gateway to innovation. The appliance industry is constantly evolving, and staying ahead of the curve is key. A factory that prides itself on innovation will offer you cutting-edge features and designs, keeping your products competitive in a rapidly changing market.

Thirdly, the reputation of the factory speaks volumes about the quality of their products. When you source from a well-established and respected manufacturer, you’re not just buying an air fryer; you’re buying into a brand that stands for reliability and excellence. This can significantly boost your own brand’s credibility among consumers.

Moreover, a reliable air fryer factory is equipped to handle large-scale production. Whether you’re a small business or a large retailer, the ability to scale up production without compromising on quality is essential. A factory with a strong supply chain and efficient production processes can ensure timely delivery, which is crucial for meeting customer demand.

Safety is another critical factor. Air fryers, like all kitchen appliances, must adhere to strict safety standards. A reliable factory will have rigorous quality control measures in place to ensure that every air fryer meets these standards, thus protecting both your customers and your business from potential liabilities.

In addition to safety and quality, a reliable air fryer factory also values customer service. They understand that communication is key to building a successful business relationship. From the initial inquiry to post-sales support, a factory that prioritizes customer satisfaction will be there to answer your questions, resolve any issues, and provide the necessary training for your team.

Furthermore, the environmental impact of your products should not be overlooked. A responsible air fryer factory will use sustainable materials and practices, aligning with today’s eco-conscious consumer base. This not only benefits the environment but can also be a selling point for your brand.

Another aspect to consider is the factory’s ability to customize. The market is diverse, and having the option to tailor the air fryer to specific customer needs can give you a competitive edge. A reliable factory will work with you to create a product that meets your unique specifications.

Lastly, a reliable air fryer factory is also a source of valuable insights and industry knowledge. They can provide you with market trends, consumer preferences, and product development advice, helping you make informed decisions for your business.

In summary, a reliable air fryer factory is more than just a supplier; it’s a partner in your business success. From quality and innovation to safety, customer service, and environmental responsibility, the right factory can elevate your brand and ensure that your customers receive a product they can trust. So, when it comes to sourcing air fryers, don’t settle for less. Invest in a factory that meets all these criteria, and you’ll be well on your way to a thriving business.

In the bustling world of kitchen appliances, the air fryer has emerged as a game-changer, offering a healthier alternative to deep-frying. When it comes to sourcing these innovative gadgets, the reliability of the factory producing them is paramount. Here’s what truly sets a reliable air fryer factory apart:

Consistent Quality Control MeasuresA reliable air fryer factory maintains stringent quality control processes to ensure every unit that leaves the assembly line meets the highest standards. This means rigorous testing for durability, performance, and safety. From the materials used to the final assembly, every detail is scrutinized to guarantee a high-quality product.

Advanced Manufacturing TechniquesThe reliability of an air fryer factory is often a reflection of its manufacturing capabilities. Cutting-edge technology and advanced techniques are employed to create air fryers that are not only efficient but also user-friendly. Look for factories that invest in CNC machines, robotic assembly lines, and automated quality checks.

Innovative Design and R&DAn air fryer factory that prides itself on reliability is likely to be at the forefront of design and research and development (R&D). They should be continuously innovating to improve existing models and exploring new technologies that could enhance the user experience. This could include features like smart connectivity, energy efficiency, and improved safety features.

Certifications and ComplianceReliable factories adhere to international standards and have the necessary certifications to prove it. Look for certifications such as CE, UL, RoHS, and ETL, which ensure that the air fryers meet safety and environmental regulations. These certifications are a clear indicator that the factory takes its responsibility to the consumer seriously.

Strong Supply Chain and Raw Material SourcingThe reliability of an air fryer factory is also influenced by its supply chain. A robust supply chain ensures a steady flow of high-quality raw materials. Reliable factories have partnerships with trusted suppliers who provide premium components, which is crucial for the longevity and performance of the final product.

Customer Support and After-Sales ServiceA reliable air fryer factory understands that the relationship doesn’t end once the product is sold. They offer comprehensive customer support and after-sales service, including troubleshooting guides, warranty policies, and easy-to-access customer service. This level of commitment to customer satisfaction is a hallmark of a trustworthy manufacturer.

Feedback Loop and Continuous ImprovementA factory that values reliability actively seeks feedback from customers and uses it to improve its products and processes. They may conduct surveys, collect reviews, and engage in market research to stay ahead of consumer needs and industry trends. This proactive approach to feedback is a sign of a company that is committed to excellence.

Scalability and Production CapacityThe ability to scale production without compromising quality is a key aspect of reliability. A factory that can handle increased demand without sacrificing the integrity of its products is one that can be counted on to meet deadlines and deliver on promises.

Financial Stability and Track RecordA reliable air fryer factory is financially stable and has a proven track record in the industry. This stability ensures that the factory can invest in its operations, maintain its quality standards, and continue to innovate. Check their history, look for longevity in the market, and assess their financial health.

Adaptability to Market ChangesThe kitchen appliance industry is dynamic, with new trends and technologies emerging regularly. A reliable factory is adaptable, able to pivot and respond to market changes swiftly. They stay informed about consumer preferences and regulatory changes, ensuring that their products remain relevant and compliant.

In conclusion, a reliable air fryer factory is characterized by its commitment to quality, innovation, compliance, and customer satisfaction. By evaluating these aspects, you can be confident in choosing a manufacturer that will deliver a product that not only meets but exceeds your expectations.

When it comes to finding a reliable air fryer factory, understanding the market and staying abreast of industry trends is crucial. This knowledge not only helps in identifying potential suppliers but also ensures that you’re getting the most up-to-date and innovative products. Here are some key aspects to consider when delving into market research and keeping an eye on industry trends:

Identifying Market Demands: It’s essential to understand the current demand for air fryers. Are they becoming a staple in households or are they niche products? Look at sales data, market reports, and consumer preferences to gauge the popularity of air fryers. This can help you determine whether there’s a stable market for your product or if there’s potential for growth.

Technological Advancements: The air fryer market is rapidly evolving with new technologies. Stay informed about the latest features like smart technology integration, improved efficiency, and healthier cooking options. Understanding these advancements can help you choose a factory that’s capable of producing cutting-edge products.

Regulatory Compliance: Different regions have varying regulations regarding electrical appliances. It’s important to research the compliance standards for air fryers in your target markets. A reliable factory will be well-versed in these regulations and will ensure that their products meet all necessary safety and environmental standards.

Competitor Analysis: Look at the competition to see what’s working and what’s not. Note the strengths and weaknesses of popular air fryer brands. This can give you insights into what customers are looking for and help you differentiate your product in the market.

Emerging Markets: Keep an eye on emerging markets where air fryers might be gaining traction. These markets can offer new opportunities for growth and partnerships. Understanding the cultural and economic factors that influence these markets can be invaluable.

E-commerce Influence: With the rise of online shopping, it’s important to consider how e-commerce is shaping the air fryer market. Research the popularity of online sales platforms and the preferences of online consumers. A factory that understands the e-commerce landscape can help you tailor your product to meet these demands.

Sustainability and Eco-Friendly Practices: More consumers are conscious of the environmental impact of their purchases. Look for factories that prioritize sustainable practices and use eco-friendly materials. This not only aligns with consumer values but can also be a unique selling point for your brand.

Supply Chain Dynamics: Investigate the supply chain of potential factories. A reliable supplier will have a stable and efficient supply chain that ensures timely delivery of raw materials and finished products. This can prevent production delays and maintain inventory levels.

Industry Reports and Publications: Subscribe to industry reports, journals, and newsletters to stay informed about the latest trends and forecasts. These resources can provide in-depth analysis and predictions that can guide your decision-making process.

Social Media and Online Forums: Social media platforms and online forums are treasure troves of consumer feedback and product reviews. Monitor these platforms to understand what consumers are saying about air fryers and what features they value the most.

By thoroughly researching the market and staying updated on industry trends, you’ll be better equipped to choose a reliable air fryer factory that can meet your needs and help you succeed in the competitive appliance market.

In the bustling world of kitchen appliances, an air fryer manufacturer stands as a cornerstone in the culinary landscape. When seeking a reliable partner in this domain, there are several key qualities to consider that can make all the difference in the quality and success of your products.

Quality Control and StandardsThe foundation of a reliable air fryer manufacturer lies in its stringent quality control processes. Look for a factory that adheres to international standards such as ISO 9001, which ensures that every product meets a high level of quality. This means regular inspections, rigorous testing, and a commitment to continuous improvement. A manufacturer that prioritizes quality will not only produce air fryers that last but also maintain a reputation for excellence.

Innovation and Design CapabilitiesInnovation is the heartbeat of any thriving industry, and air fryers are no exception. A reputable manufacturer should be at the forefront of technological advancements, offering cutting-edge features that enhance user experience. This could include smart technology for remote monitoring, energy-efficient designs, and unique cooking capabilities. Their design team should be capable of not just keeping up with trends but also shaping them.

Customer Reviews and TestimonialsWord of mouth is a powerful tool, and in the digital age, it’s easier than ever to gauge customer satisfaction. Look for an air fryer manufacturer with a wealth of positive reviews and testimonials. These can often be found on the manufacturer’s website, social media platforms, and third-party review sites. Pay attention to what customers are saying about the durability, ease of use, and performance of the air fryers.

Certifications and ComplianceCertifications are more than just pieces of paper—they are a testament to a manufacturer’s dedication to safety and environmental responsibility. Seek out manufacturers who are certified by recognized bodies such as the CE mark, which signifies compliance with European safety standards. Additionally, look for compliance with energy efficiency standards like ENERGY STAR, which can be a significant selling point for your customers.

Production Capacity and ScalabilityThe ability to scale production is crucial for manufacturers that want to grow with their customers. An air fryer factory with a robust production capacity can handle increased orders without compromising on quality. This scalability ensures that you can meet demand as your business expands, whether you’re selling to a local market or aiming for global distribution.

Supply Chain ManagementA reliable air fryer manufacturer will have a well-managed supply chain that ensures the availability of components and materials. This includes partnerships with trusted suppliers who can provide high-quality parts on time. A strong supply chain minimizes the risk of production delays and ensures that the manufacturing process runs smoothly.

After-Sales Service and SupportThe journey doesn’t end once the air fryers are sold. A manufacturer that stands behind its products will offer comprehensive after-sales service and support. This can include warranty coverage, technical assistance, and a responsive customer service team. A manufacturer with a good reputation for customer support can be a valuable asset, as it can enhance the overall customer experience and loyalty.

Environmental ResponsibilityIn an era where sustainability is a growing concern, a manufacturer’s commitment to environmental responsibility can be a significant factor. Look for a factory that uses eco-friendly materials, minimizes waste, and operates with a low carbon footprint. This not only aligns with the values of many consumers but can also be a marketing advantage.

Innovation in Packaging and DistributionPackaging is often overlooked but plays a vital role in protecting products during shipping and ensuring they arrive in pristine condition. A manufacturer that invests in innovative packaging solutions can help reduce damage and improve customer satisfaction. Additionally, efficient distribution practices can help get your air fryers to market quickly and cost-effectively.

Adaptability to Market ChangesThe kitchen appliance industry is dynamic, with consumer preferences and market demands shifting rapidly. A reliable air fryer manufacturer should be adaptable, capable of quickly responding to market changes and evolving trends. This could involve introducing new models, modifying existing designs, or embracing new technologies.

Financial Stability and Track RecordFinally, consider the financial stability and track record of the manufacturer. A strong financial foundation means they are less likely to face production or supply chain disruptions. A proven history of successful operations can provide peace of mind that they will be a reliable partner for the long term.

By focusing on these key qualities, you can identify an air fryer manufacturer that is not just reliable but also a strategic partner in your business endeavors.

Navigating the world of air fryer manufacturers can feel like a treasure hunt. To ensure you find a reliable partner, it’s crucial to build a strong network and establish contacts within the industry. Here’s how to do it effectively:

Leverage Trade Shows and ExposTrade shows are a goldmine for networking. They bring together manufacturers, distributors, and industry professionals under one roof. Attend these events to meet potential suppliers face-to-face. Engage in conversations, ask questions, and gather business cards. Remember, a well-attended trade show can lead to valuable connections and insights into the latest industry trends.

Join Industry Forums and AssociationsIndustry forums and associations are like secret societies for those in the know. They offer memberships that provide access to a wealth of resources, including networking opportunities. By joining these groups, you can participate in discussions, attend webinars, and even volunteer for events. This active involvement can put you on the radar of influential industry players.

Utilize Online Platforms and Social MediaIn today’s digital age, online platforms and social media are invaluable tools for networking. LinkedIn, for instance, is a professional networking site where you can connect with manufacturers, distributors, and even potential customers. Follow industry leaders, join relevant groups, and share your insights. Platforms like Facebook, Twitter, and Instagram can also be used to engage with the community, showcasing your expertise and building your brand.

Attend Local and Regional EventsSometimes, the best connections are made in your own backyard. Attend local business events, mixers, and networking sessions. These can be hosted by your local chamber of commerce, business associations, or even community organizations. These events are a great way to meet a diverse group of professionals who might have connections in the air fryer industry.

Collaborate with Distributors and RetailersDistributors and retailers are often the first point of contact for manufacturers. Building a relationship with them can provide valuable insights into the market. Ask for referrals, and consider attending trade shows or events they sponsor. They can offer a glimpse into consumer preferences and the competitive landscape.

Participate in Industry Conferences and SeminarsIndustry conferences and seminars are another excellent way to network. These events often feature keynotes from industry experts and offer workshops that can enhance your knowledge. Engage in these sessions, and don’t hesitate to approach speakers or fellow attendees to discuss your interests and experiences.

Build Relationships Through Mutual InterestsNetworking isn’t just about your business goals; it’s about building genuine relationships. Find common ground with other professionals, whether it’s a shared hobby, a passion for innovation, or a mutual respect for the industry. When you connect on a personal level, the business relationship tends to follow naturally.

Maintain Regular CommunicationOnce you’ve made a connection, keep the line of communication open. Regularly check in with your contacts, share updates, and offer assistance when possible. Building a strong network is about nurturing relationships over time.

Seek Out Mentorship OpportunitiesDon’t underestimate the value of mentorship. Seek out seasoned professionals in the air fryer industry who can provide guidance and advice. A good mentor can offer invaluable insights and help you navigate the complexities of the market.

Be Prepared to Offer ValueNetworking is a two-way street. While you’re seeking to learn and grow, be prepared to offer value to others. Share your expertise, offer to help with projects, or simply listen to their challenges. When you’re seen as someone who adds value, you’ll be more likely to be remembered and recommended.

Stay Informed and EngagedThe air fryer industry is constantly evolving, with new technologies and consumer trends emerging regularly. Stay informed by reading industry publications, attending webinars, and keeping an eye on market research reports. Being well-informed will not only help you in your own business but also make you a more engaging and valuable contact for others.

Remember the Power of ReferralsReferrals are a powerful tool in networking. When someone you trust recommends a contact, it carries a lot of weight. Encourage your network to refer you to others they believe could benefit from your partnership.

By actively engaging in these networking strategies, you’ll be well on your way to establishing a robust network of industry contacts within the air fryer manufacturing sector. Remember, it’s not just about the number of connections you make; it’s about the quality and depth of those relationships.

Understanding the credentials of an air fryer manufacturer is akin to decoding a code that guarantees the quality and safety of the products you’re considering. Here’s what to look for in terms of certifications and compliance:

Safety Certifications: When it comes to kitchen appliances, safety should be paramount. Look for manufacturers that hold certifications from reputable organizations like Underwriters Laboratories (UL), Intertek, or TÜV Rheinland. These certifications ensure that the air fryers meet stringent safety standards, including electrical and fire safety.

Quality Assurance: ISO certifications are a gold standard in quality management. A manufacturer with ISO 9001 certification demonstrates a commitment to quality in all aspects of their operations, from design and production to customer service. This means they have processes in place to consistently meet customer requirements and enhance customer satisfaction.

Environmental Responsibility: The world is moving towards sustainability, and so should your air fryer manufacturer. Look for certifications like ISO 14001, which focuses on environmental management. This indicates that the factory has systems to minimize environmental impact, such as reducing waste and using energy-efficient practices.

Health and Safety Regulations: Food safety is critical, especially when dealing with appliances that come into contact with food. Certifications like HACCP (Hazard Analysis and Critical Control Points) ensure that the factory has a systematic approach to managing food safety. This includes identifying potential hazards, assessing and controlling risks, and ensuring that the air fryers are clean and safe for food contact.

Product Compliance: Different regions have different regulations regarding electrical products. Look for manufacturers that are certified to comply with the specific standards of the markets they serve. For example, CE marking in Europe indicates conformity with the European Union’s safety, health, and environmental requirements. In the United States, compliance with the FCC and UL standards is crucial.

Certifications for Raw Materials: The quality of raw materials can significantly impact the final product. Check if the manufacturer sources materials from suppliers that are certified for quality and sustainability. For instance, certifications like FSC (Forest Stewardship Council) for wood materials or BPA-free certifications for plastic components can provide peace of mind regarding the product’s integrity.

Regular Audits and Inspections: A reliable manufacturer should be open to third-party audits and inspections. Regular audits can reveal any compliance issues or potential risks before they become significant problems. It’s a sign of transparency and a commitment to maintaining high standards.

Industry Awards and Recognitions: Sometimes, industry awards can serve as a good indicator of a manufacturer’s reputation. Awards from trade associations or consumer organizations can highlight their expertise and dedication to excellence.

Customer Feedback: While certifications and awards are important, customer feedback can sometimes reveal the most about a factory’s reliability. Look for reviews that mention compliance with standards and the overall quality of the air fryers.

Longevity in the Market: A manufacturer that has been in business for a long time and has a strong presence in the market is more likely to be compliant with current standards and regulations. They’ve likely navigated through various changes and have adapted their practices to meet evolving requirements.

Continuous Improvement: A reliable air fryer manufacturer should be focused on continuous improvement. This can be seen through their willingness to invest in new technologies, train their staff, and update their processes to stay ahead of compliance standards.

Remember, checking factory certifications and compliance is not just about meeting legal requirements; it’s about ensuring that the air fryers you’re considering are safe, of high quality, and produced in an environmentally responsible manner.

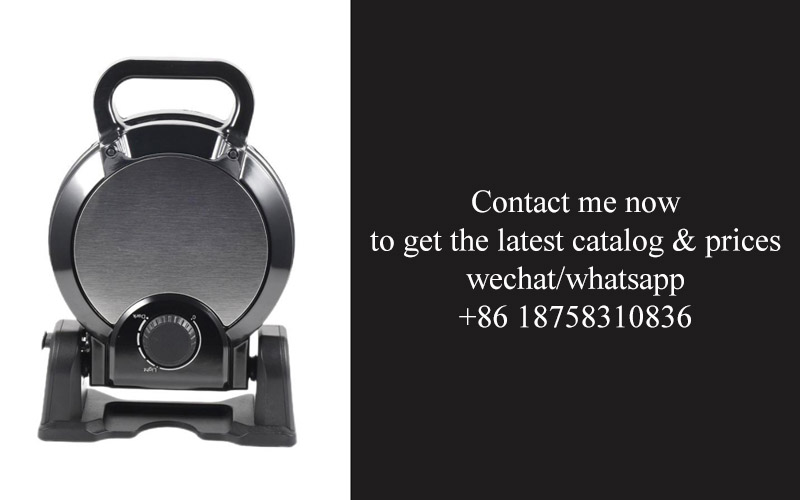

Understanding the intricacies of an air fryer’s manufacturing process is crucial when seeking a reliable supplier. Requesting samples and conducting trials can be a pivotal step in this process, offering a tangible way to assess the quality and performance of the products you’re considering. Here’s how to navigate this phase effectively:

1. Specify Your RequirementsBefore you request samples, it’s essential to have a clear understanding of what you need. Define the specific features, such as capacity, power, and temperature control, that your air fryer should have. This ensures that the samples you receive align with your exact requirements.

2. Quality of MaterialsInspect the materials used in the air fryer samples. High-quality materials often contribute to better durability and performance. Look for sturdy construction, non-toxic materials, and the absence of any sharp edges or loose parts that could pose a safety hazard.

3. Functionality and PerformanceTest the functionality of the air fryer by cooking with it. Pay attention to how it heats up, the distribution of heat, and the cooking times. A reliable air fryer should maintain consistent temperatures and cook food evenly, reducing the risk of burning or undercooking.

4. Energy EfficiencyEnergy consumption is a significant factor in the long-term cost of owning an air fryer. Check if the device has an energy-saving mode or if it’s designed to be energy-efficient. This not only benefits the environment but also your utility bills.

5. User Interface and ControlsThe ease of use is crucial. A user-friendly interface with clear controls can make a big difference in the consumer experience. Ensure that the air fryer’s controls are intuitive and that the display is easy to read.

6. Noise LevelsNo one wants a loud kitchen appliance. Test the noise levels of the air fryer during operation. A quieter machine can make cooking a more pleasant experience.

7. Packaging and ShippingThe way a product is packaged and shipped can be indicative of the care taken in its production. Check if the samples are well-packed to prevent damage during transit. This also gives you an idea of how the manufacturer handles logistics.

8. Customer SupportA reliable manufacturer should offer excellent customer support. During your trial, reach out to the manufacturer with any questions or concerns. How quickly and effectively they respond can be a good indicator of their commitment to customer satisfaction.

9. Feedback and IterationCollect feedback from your trials and share it with the manufacturer. This iterative process allows you to refine your requirements and gives the manufacturer valuable insights into their product’s performance in real-world scenarios.

10. Longevity and WarrantyAssess the longevity of the air fryer by looking at the warranty offered. A longer warranty period often suggests that the manufacturer has confidence in the durability of their product.

11. Scalability and Production CapacityIf you’re looking to establish a long-term relationship with the manufacturer, consider their production capacity. Can they scale up to meet your growing demands? This is especially important if you’re planning to expand your product line or increase your market share.

12. Legal and Ethical StandardsEnsure that the manufacturer adheres to legal and ethical standards. This includes compliance with labor laws, environmental regulations, and fair trade practices.

By meticulously examining these aspects through your sample requests and trials, you can gain a comprehensive understanding of the air fryer manufacturer’s capabilities and the quality of their products. This due diligence can prevent costly mistakes and set the stage for a successful partnership.

Understanding the ins and outs of negotiation is crucial when seeking to establish a partnership with an air fryer manufacturer. It’s not just about locking in the best price; it’s about creating a mutually beneficial relationship that can stand the test of time. Here are some key strategies to consider:

1. Know Your Market and CostsBefore diving into negotiations, it’s essential to have a clear understanding of the market rates for air fryers and the costs associated with production. This includes raw materials, labor, and any additional expenses. Being well-informed allows you to negotiate from a position of strength, knowing what is a fair price and what might be a deal-breaker.

2. Define Your Objectives ClearlyBefore you even start discussing terms with a manufacturer, know exactly what you want to achieve. Are you looking for the lowest cost, the highest quality, or a balance between the two? Having clear objectives will help you stay focused during negotiations and avoid getting sidetracked by less important details.

3. Understand the Manufacturer’s PerspectiveEvery manufacturer has their own set of priorities and constraints. Understanding these can help you tailor your negotiation strategy. For instance, if the manufacturer is heavily invested in new technology, you might be able to negotiate better terms if you agree to a longer-term contract that includes their latest innovations.

4. Flexibility in TermsBe prepared to be flexible. This doesn’t mean you should compromise on your core values or minimum requirements, but it does mean being open to different terms that might include volume discounts, payment schedules, or even co-branding opportunities. The key is to find a middle ground that works for both parties.

5. Communication is KeyClear and open communication is essential in negotiations. Avoid hidden agendas or misleading information, as this can erode trust and damage the relationship. Be honest about your needs and expectations, and listen actively to the manufacturer’s concerns and suggestions.

6. Consider the Long-Term RelationshipNegotiations are not just about the immediate deal; they’re about building a long-term partnership. Think about how the relationship can evolve over time. Will you need to increase your order volume? Can the manufacturer help with product development or customization? These considerations can influence the terms you negotiate.

7. Use a Win-Win ApproachA win-win negotiation is where both parties feel they have gained something valuable. This approach is more likely to lead to a sustainable relationship. Instead of focusing on what you can get out of the deal, think about how you can create value for the manufacturer as well, such as by providing them with a steady stream of orders or access to new markets.

8. Avoid Rushing the ProcessTake your time to evaluate the terms being offered. Rushing into a decision can lead to missed opportunities or unfavorable terms. Give yourself space to consider the implications of each term and to weigh the pros and cons.

9. Be Prepared to Walk AwayIf the negotiations are not going in a direction that aligns with your objectives, be prepared to walk away. This is a powerful negotiating tool, as it shows the manufacturer that you have options and are not desperate for the deal. However, use this tactic judiciously, as it can also harm your relationship if not handled properly.

10. Document EverythingOnce you’ve reached an agreement, make sure to document all the terms clearly. This includes the specifics of the contract, any verbal agreements, and any additional understandings that were made during the negotiation process. A well-documented agreement helps prevent misunderstandings and ensures that both parties are on the same page.

Building relationships with air fryer manufacturers is about more than just the transactional aspects of the business. It’s about fostering trust, mutual respect, and a shared vision for the future. By approaching negotiations with these principles in mind, you can create a partnership that is both profitable and sustainable.

Navigating the nuances of selecting the right air fryer factory can be a delicate balance between quality, cost, and reliability. Here are some final tips to guide you through the selection process:

Understand the Market LandscapeKeep your finger on the pulse of the market. The air fryer industry is dynamic, with new innovations and technologies emerging regularly. Stay informed about the latest market trends, consumer preferences, and technological advancements in the field.

Visit the FactoryOnce you’ve narrowed down your list of potential suppliers, it’s crucial to visit their factory. A physical visit allows you to assess the factory’s cleanliness, organization, and overall efficiency. You can also observe the work ethic and professionalism of the staff.

Inspect the Production ProcessObserve how the air fryers are made. Look for a factory that uses modern machinery and techniques. The production process should be seamless, with clear steps and quality checks at each stage. Ensure that the factory has a robust system for identifying and rectifying any defects.

Quality AssuranceA reliable air fryer factory should have stringent quality assurance protocols. Ask about their quality control measures, including any certifications they hold (like ISO 9001). They should be able to provide detailed information about how they test for durability, safety, and performance.

Sample TestingRequest samples before placing a large order. This allows you to evaluate the air fryer’s design, build quality, and functionality firsthand. Pay attention to the finish, fit, and finish of the product. A well-crafted sample is a good indicator of what you can expect from bulk orders.

Long-Term SupportConsider the level of support the factory offers. A reliable supplier will be willing to assist with technical queries, after-sales service, and even modifications to the product to better suit your needs. A good relationship with your supplier can lead to long-term benefits.

Cost AnalysisWhile cost is a significant factor, it shouldn’t be the only one. Compare the prices of similar products from different factories, but also consider the overall value. A slightly higher cost might be justified by better quality, durability, or customer service.

Legal and Ethical StandardsEnsure that the air fryer factory adheres to legal and ethical standards. This includes compliance with labor laws, environmental regulations, and fair trade practices. A factory that prioritizes ethical operations is more likely to be reliable and sustainable.

FlexibilityA reliable air fryer factory should be able to accommodate your specific requirements. This could range from customization to flexible production timelines. The ability to adapt to your needs is a sign of a supplier that values its relationship with you.

Feedback and ReferencesAsk for feedback from other clients. Personal testimonials and case studies can provide valuable insights into the factory’s reliability and customer satisfaction. References can also help you verify the factory’s claims.

ProfessionalismThe way a factory handles inquiries, orders, and communications reflects its professionalism. A responsive, courteous, and efficient team is a good sign that you’re dealing with a reliable supplier.

Longevity in the MarketConsider the factory’s history in the industry. A well-established factory with a proven track record is more likely to be reliable than a new one. Experience can lead to better processes, a deeper understanding of market needs, and a more robust product.

By taking these final tips into account, you can make a more informed decision when selecting the right air fryer factory. Remember, building a strong partnership with a reliable supplier is key to the success of your business.