Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, one tool has quietly emerged as a staple for sandwich enthusiasts: the heavy-duty sandwich press. This simple yet ingenious device has seen a surge in popularity, not just for its ability to create the perfect grilled sandwich, but also for its versatility and durability. As we delve into the intricacies of this kitchen gadget, it becomes clear that the heavy-duty sandwich press is not just a trend—it’s a game-changer.

In the bustling world of kitchen appliances, one product stands out for its versatility and convenience: the heavy duty sandwich press. These robust appliances have become a staple in many homes and restaurants, offering a perfect solution for those who love a good, crispy sandwich. But where do these mighty sandwich presses come from? Enter the heavy duty sandwich press factories, the unsung heroes of the culinary appliance industry.

These factories are the heart of the sandwich press manufacturing process, where raw materials are transformed into the durable and reliable tools that make our favorite meals a breeze. From the initial design stages to the final quality checks, these factories are a symphony of precision and innovation.

At the heart of these factories lies a meticulous attention to detail. The production line is a testament to the craftsmanship that goes into creating a heavy duty sandwich press. Each machine is designed to withstand the rigors of daily use, ensuring that it can endure the pressure and heat required to produce a perfectly toasted sandwich.

The journey of a sandwich press from conception to completion is a fascinating one. It begins with selecting the right materials. High-quality stainless steel is often chosen for its durability and resistance to rust. Aluminum is another popular choice for its even heat distribution. These materials are then shaped into the press’s frame, which forms the foundation of the appliance.

Once the frame is in place, the engineering team gets to work on the intricate details. The heating elements are precision-welded into the sandwich press’s top and bottom plates, ensuring consistent heat distribution. The hinges are carefully crafted to provide smooth operation, while the handles are ergonomically designed for comfort and ease of use.

As the sandwich press takes shape, it moves through various stages of assembly. Workers meticulously fit the heating elements, the bread guides, and the non-stick surfaces. Each component is checked for quality and fit, ensuring that the final product will perform to the highest standards.

The attention to detail doesn’t stop at the assembly line. The finishing touches are applied with the same level of care. The sandwich press is polished to a gleaming finish, and any imperfections are buffed away. This not only enhances the aesthetic appeal but also ensures that the appliance is easy to clean and maintain.

Once the sandwich press is fully assembled, it undergoes rigorous testing. These tests are designed to simulate years of use, ensuring that the appliance can withstand the demands of a busy kitchen or a casual home setting. The sandwich press is heated, cooled, and pressed repeatedly, all while being monitored for any signs of wear or malfunction.

Innovation is a key driver in the world of heavy duty sandwich press factories. These factories are always looking for new ways to improve their products. This could mean developing new materials that provide better heat retention or creating unique features that enhance the user experience. Some factories even invest in cutting-edge technology to streamline the production process, ensuring that each sandwich press that leaves the factory is a masterpiece of engineering.

The market for heavy duty sandwich presses is dynamic, with consumer preferences constantly evolving. These factories stay on top of the latest trends, whether it’s the demand for compact models for smaller kitchens or the integration of smart features that allow for precise temperature control. By staying attuned to these changes, they can produce sandwich presses that not only meet but exceed customer expectations.

The success of a heavy duty sandwich press factory is not just measured by the quantity of products it produces but by the quality and reliability of those products. These factories understand that the key to customer satisfaction lies in the durability and performance of their appliances. That’s why they invest in skilled labor, state-of-the-art machinery, and stringent quality control measures.

In conclusion, the heavy duty sandwich press factory is a place where art meets science. It’s a place where the dream of a perfect sandwich is turned into reality. From the selection of materials to the final quality checks, every step in the production process is a commitment to excellence. These factories are the backbone of the sandwich press industry, ensuring that every kitchen has the tool it needs to create the perfect meal.

In recent years, the kitchen appliances market has witnessed a significant surge in the popularity of sandwich presses. This trend is not just a fleeting fad but a testament to the evolving culinary preferences and the quest for convenience in everyday cooking. The once humble sandwich press has transformed into a staple in many kitchens around the world.

One of the primary drivers behind this rise is the increasing demand for quick and easy meals. With busy lifestyles becoming the norm, individuals are looking for time-saving solutions that don’t compromise on taste. Sandwich presses offer a perfect solution, allowing for the creation of delicious sandwiches in mere minutes, right in the comfort of one’s home.

The versatility of sandwich presses is another key factor contributing to their popularity. These appliances can be used to make not only classic sandwiches but also a variety of other food items like grilled cheese, panini, and even stuffed pastries. This flexibility has made sandwich presses a favorite among food enthusiasts and those who enjoy experimenting with different recipes.

Additionally, the convenience of sandwich presses cannot be overstated. With their compact size and ease of use, these appliances are ideal for individuals living in small spaces or for those who prefer not to clutter their countertops with numerous kitchen gadgets. The clean and simple design of sandwich presses also appeals to those who value a clutter-free kitchen environment.

The evolution of the sandwich press itself has played a crucial role in its rise. Modern sandwich presses come equipped with various features that enhance both the cooking experience and the final product. From adjustable heat settings to non-stick surfaces and temperature indicators, these appliances are designed to cater to a wide range of cooking preferences and needs.

Furthermore, the culinary world has embraced the sandwich press as a tool for creativity. Chefs and home cooks alike have found new and exciting ways to use these appliances, leading to the development of unique recipes and the creation of gourmet sandwiches that were once unimaginable. The sandwich press has become a canvas for culinary artisans to showcase their skills and push the boundaries of traditional sandwich making.

The market has also seen a growing trend towards healthier eating habits, and sandwich presses fit seamlessly into this shift. Users can control the ingredients and preparation methods, ensuring that their sandwiches are not only delicious but also nutritious. The ability to use fresh, whole-grain breads and to incorporate a variety of fillings from lean proteins to vegetables and fruits has made sandwich presses a health-conscious choice.

Another factor that has contributed to the rise of sandwich presses is the influence of social media and food bloggers. These platforms have showcased the versatility and creativity of sandwich presses, inspiring countless individuals to invest in their own units. The viral nature of certain sandwich recipes and the popularity of sandwich-making challenges have further fueled the trend.

In the commercial sector, the demand for sandwich presses has also been on the rise. Many restaurants and cafes have integrated these appliances into their menu offerings, allowing them to serve freshly made sandwiches to their customers. This has created a new wave of interest in sandwich presses, as both consumers and businesses seek to capitalize on this growing segment of the market.

The environmental movement has also played a part in the sandwich press’s ascent. As more people become aware of the impact of single-use plastics on the planet, the idea of using a reusable sandwich press to make a meal at home becomes even more appealing. This eco-conscious approach aligns with the values of sustainability and has added to the sandwich press’s appeal.

Lastly, the global pandemic has had a significant effect on the kitchen appliances market, including sandwich presses. With people spending more time at home, the need for home cooking and baking has increased. Sandwich presses have become a go-to tool for those looking to enjoy a hot, freshly made meal without the need for complex cooking techniques.

In conclusion, the rise of sandwich presses in the kitchen appliances market is a multifaceted phenomenon driven by convenience, versatility, health consciousness, and the influence of modern technology and social media. As the trend continues to grow, it’s clear that the sandwich press is not just a kitchen gadget but a symbol of the changing landscape of home cooking.

In the ever-evolving kitchen appliances market, the demand for heavy-duty sandwich presses has seen a significant surge. This trend is not just a fleeting fad but a reflection of several key factors that highlight the need for these robust and versatile cooking tools.

The surge in popularity of artisanal and gourmet foods has spurred a wave of culinary enthusiasts who are not afraid to invest in quality appliances. Heavy-duty sandwich presses cater to this niche market by providing a means to craft perfect, golden-brown sandwiches with precision and consistency. From classic melts to elaborate gourmet creations, these presses have become a staple in many kitchens.

Home chefs are increasingly looking for appliances that can handle the rigors of frequent use without succumbing to wear and tear. The durability of heavy-duty sandwich presses is a major draw, as they are often made from high-quality materials like stainless steel, which can withstand the heat and pressure of cooking without bending or warping over time.

Moreover, the convenience factor cannot be overlooked. Sandwich presses save time and effort by allowing users to cook a meal in minutes, rather than the longer process of pan-frying or grilling. In a fast-paced world where time is a precious commodity, the efficiency of these appliances is a compelling reason for their popularity.

The rise of social media has also played a role in the increased demand for heavy-duty sandwich presses. With influencers and food bloggers showcasing their culinary creations, there’s a sense of community and competition that drives the desire for the best tools to make those mouthwatering sandwiches. These presses are not just for personal use; they are also seen as a status symbol among food enthusiasts.

Another aspect that has fueled the need for heavy-duty sandwich presses is the variety of functionalities they offer. Modern models come with adjustable heat settings, non-stick surfaces, and even features like a locking mechanism to prevent the contents from spilling. This versatility means that these presses can be used to cook a wide range of foods, not just sandwiches, such as paninis, grilled cheese, and even burgers.

For those with dietary restrictions or preferences, the ability to control the cooking temperature is crucial. Heavy-duty sandwich presses allow users to achieve the perfect level of doneness, whether they prefer a well-done, crispy exterior or a soft, melting interior. This level of customization is something that traditional cooking methods often cannot provide.

The market has also seen an increase in eco-conscious consumers who are seeking appliances that are energy-efficient. Heavy-duty sandwich presses are designed to use less energy than other cooking methods, such as electric skillets or grills, which is an attractive feature for environmentally friendly households.

In the realm of professional kitchens, the need for heavy-duty sandwich presses is equally apparent. Restaurants and cafes often serve a high volume of sandwiches and need reliable equipment that can withstand the test of time. These presses are built to last, making them a wise investment for any establishment that values consistency and customer satisfaction.

The rise of food trucks and pop-up restaurants has also contributed to the demand for heavy-duty sandwich presses. These mobile kitchens require portable, robust appliances that can withstand the elements and provide high-quality food on the go. The portability and durability of these presses make them ideal for such dynamic environments.

Lastly, the convenience of clean-up is a key consideration for many consumers. Heavy-duty sandwich presses typically come with non-stick surfaces that make them easy to clean, reducing the hassle of post-cooking maintenance. This feature is particularly appealing to busy individuals who want to minimize the time spent on kitchen chores.

In summary, the need for heavy-duty sandwich presses in the kitchen appliances market is a multifaceted phenomenon. It’s driven by a love for gourmet food, the desire for convenience, the need for durability, and the growing preference for energy-efficient appliances. As the market continues to evolve, it’s clear that heavy-duty sandwich presses are here to stay, providing both home cooks and professionals with a versatile and reliable tool for creating delicious sandwiches and beyond.

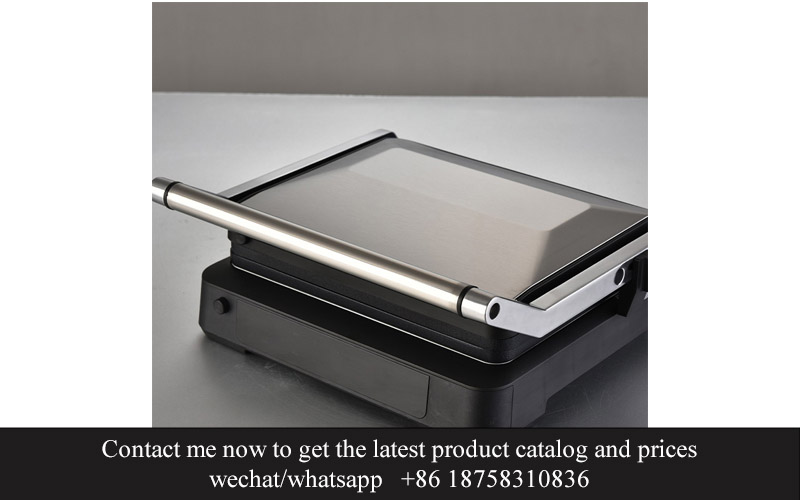

A high-quality heavy duty sandwich press is more than just a tool for making the perfect sandwich; it’s an essential appliance for anyone passionate about culinary excellence and convenience. Here are some key features that define the top-tier sandwich presses:

The Construction Material: Crafted from premium materials like stainless steel or cast aluminum, a heavy duty sandwich press boasts durability and strength. These materials not only ensure the press withstands the test of time but also provide a sleek, modern look that complements any kitchen aesthetic.

Even Heat Distribution: To achieve that perfect sear on both sides of the sandwich, a high-quality heavy duty press needs to distribute heat evenly. Look for presses with a flat, non-stick surface that prevents food from sticking and ensures consistent cooking temperatures throughout the pressing process.

Adjustable Pressure: Not all sandwiches require the same amount of pressure. A great heavy duty sandwich press offers adjustable pressure settings, allowing users to tailor the cooking intensity to their preference. Whether you want a light press for delicate ingredients or a firm press for a hearty sandwich, the ability to customize pressure is a must-have feature.

Built-In Temperature Control: Knowing the exact temperature at which your sandwich is being cooked can be crucial. Many top models come with built-in temperature controls that allow you to monitor and maintain the optimal temperature for achieving a perfectly toasted outcome every time.

Wide Opening and Deep Pans: A larger opening and deeper pans are not only more convenient for handling thicker sandwiches but also essential for ensuring that all parts of the sandwich get toasted evenly. This is particularly important for gourmet sandwiches that include fillings that can sometimes overheat or burn.

Spatula and Spreader Guides: To prevent oil or butter from escaping during the cooking process, some heavy duty sandwich presses come with spatula and spreader guides. These features help keep the sandwich together and prevent ingredients from spilling out, ensuring a neater and more uniform cooking experience.

Safety Locks and Non-Slip Feet: Safety should never be compromised, especially in the kitchen. A high-quality heavy duty sandwich press includes safety locks to prevent accidental presses and non-slip feet to keep the appliance stable on your countertop, even when it’s hot.

Detachable Parts: Cleaning a sandwich press can be a challenge, but not when it’s designed with user convenience in mind. Look for models with removable parts that can be easily washed in the dishwasher, saving you time and effort.

Energy Efficiency: In today’s eco-conscious world, energy efficiency is a significant factor. High-quality heavy duty sandwich presses are designed to use less energy without sacrificing performance, making them a greener choice for your kitchen.

Ergonomic Handles: The design of the handles can make all the difference in the usability of a sandwich press. Ergonomic handles provide a comfortable grip, reducing hand fatigue and allowing for easy and safe operation.

Long Warranty: A reputable manufacturer stands behind the quality of their product. A long warranty period, typically covering parts and labor, is a sign that the manufacturer has confidence in the durability and performance of their heavy duty sandwich presses.

In conclusion, a high-quality heavy duty sandwich press is a kitchen essential that combines durability, ease of use, and culinary versatility. With features like premium construction, even heat distribution, adjustable pressure, and thoughtful design, these presses are more than just a tool—they’re an investment in your kitchen experience.

In the heart of the bustling industrial landscape, a heavy-duty sandwich press factory hums with activity. The process is a blend of precision engineering and meticulous craftsmanship, ensuring that each press that rolls off the assembly line is a testament to quality and durability. Let’s take a peek inside the workings of such a factory.

The factory floor is a labyrinth of metal and machinery, with rows of presses, each one a marvel of design. Workers in protective gear move with purpose, their tasks as varied as they are essential. The journey of a heavy-duty sandwich press from raw materials to finished product is a story of innovation and attention to detail.

The raw materials, including stainless steel, aluminum, and various plastics, are meticulously selected for their quality and suitability for the demands of heavy-duty use. These materials are then transported to the cutting department, where skilled workers use advanced laser cutting technology to shape them into the initial components of the sandwich press.

Once cut, these components are sent to the welding station. Here, experienced welders join the pieces together with precision, ensuring that the structure of the press is strong and robust. The welding process is crucial, as it forms the backbone of the sandwich press, and any imperfection could compromise its performance over time.

Next, the assembled frame moves to the painting department. Here, a series of coats are applied to the metal components, starting with a primer to ensure adhesion and followed by a topcoat that not only enhances the appearance but also provides a protective layer against rust and corrosion. The paint is baked on at high temperatures to achieve a durable finish.

As the painted components cool, they are then sent to the assembly line. This is where the magic happens. Workers meticulously put together the various parts, including the heating elements, hinges, and handles. The precision required here is remarkable, as each component must fit perfectly within the intricate design of the sandwich press.

The heating elements are a critical component, as they are responsible for the even cooking of sandwiches. Inside the factory, these elements are tested for their resistance and durability, ensuring they can withstand repeated use without failing. The temperature control system is also calibrated to perfection, allowing for consistent cooking results every time.

Once the sandwich press is fully assembled, it moves to the testing station. Here, the press is subjected to rigorous quality checks. It is tested for its ability to press sandwiches with uniform pressure, its heat distribution, and its overall durability. The press is also evaluated for its ease of use and safety features.

If the sandwich press passes all these tests, it is then packaged. The packaging department ensures that each press is securely enclosed in a protective box, complete with a user manual and any necessary accessories. The boxes are labeled with all the necessary information, including the model number, warranty details, and safety warnings.

Finally, the finished sandwich presses are transported to distribution centers, ready to be shipped to retailers and directly to consumers. The factory’s quality control team keeps a close eye on the entire process, ensuring that every press that leaves the factory meets the highest standards of excellence.

The manufacturing process of a heavy-duty sandwich press is a testament to the dedication and skill of the engineers and workers involved. It’s a complex dance of technology and human expertise, resulting in a product that not only satisfies the demand for a perfect sandwich but also stands the test of time in the demanding environment of a busy kitchen.

In the ever-evolving world of kitchen appliances, the heavy-duty sandwich press has emerged as a staple in many homes. These appliances have seen a surge in popularity, not just for their ability to create perfect sandwiches but also for their durability and versatility. Let’s delve into the innovations that have shaped the design and technology of these sandwich presses.

The evolution of sandwich presses has led to a variety of features that cater to different cooking styles and preferences. One such innovation is the adjustable pressure system. Modern heavy-duty sandwich presses often come with a mechanism that allows users to control the amount of pressure applied to the sandwich, ensuring that it’s cooked to perfection every time.

Another innovation is the non-stick surfaces. These surfaces are not only easy to clean but also prevent the sandwiches from sticking, allowing for a seamless cooking experience. The use of high-quality materials like stainless steel and aluminum ensures that the sandwich press can withstand the heat and pressure without warping or losing its shape.

The inclusion of digital controls has also been a game-changer. Many heavy-duty sandwich presses now feature digital displays that allow users to monitor the cooking temperature and time. This precision is crucial for achieving the desired level of crispiness on the outside and tenderness on the inside of the sandwich.

One of the latest technological advancements is the inclusion of a variable temperature control. This feature allows users to adjust the heat settings according to the type of bread and fillings, ensuring that the sandwich is cooked evenly without overcooking or burning.

The design of heavy-duty sandwich presses has also seen significant improvements. For instance, the compact and sleek designs make these appliances a perfect fit for modern kitchens. They are not only space-saving but also visually appealing, with some models featuring elegant finishes that complement various kitchen aesthetics.

The handles and hinges are another area where innovation has played a key role. Modern sandwich presses often come with ergonomic handles that provide a comfortable grip, making it easier to open and close the press. The hinges are designed to withstand frequent use, ensuring that the appliance remains durable over time.

Safety features have also been a focus of innovation. Many models now include features like automatic shut-off mechanisms that turn off the press after a certain period of time to prevent overheating. This not only ensures the safety of the user but also preserves the longevity of the appliance.

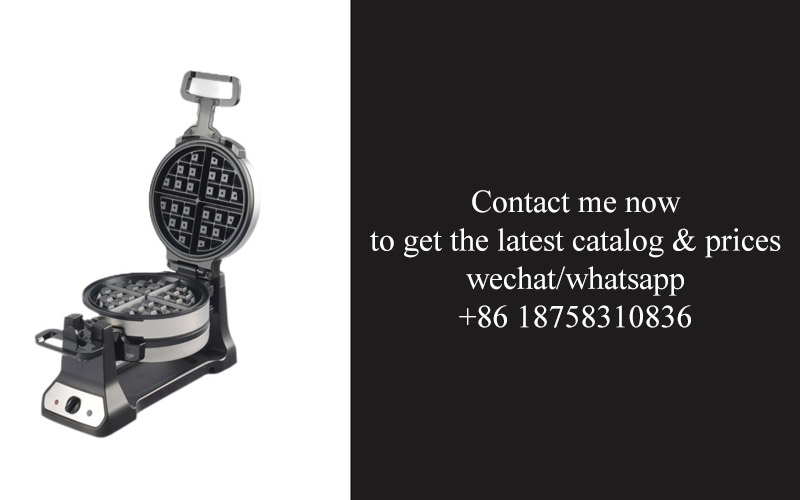

In terms of functionality, some sandwich presses have expanded their capabilities beyond just sandwiches. They can now be used to cook a variety of foods, including pancakes, omelets, and even mini pizzas. The inclusion of a reversible plate that can be used for different cooking surfaces has made these appliances even more versatile.

The integration of smart technology is another innovation that’s beginning to make its way into heavy-duty sandwich presses. Some models are now compatible with smartphone apps, allowing users to control the cooking process remotely. This feature is particularly useful for those who want to prepare their meals in advance or for those who are looking to add a touch of convenience to their cooking routine.

Lastly, the sustainability aspect has not been overlooked. Many manufacturers are now focusing on creating sandwich presses that are eco-friendly, using recycled materials and energy-efficient designs. This commitment to sustainability is not only beneficial for the environment but also appeals to consumers who are increasingly conscious of their ecological footprint.

In conclusion, the innovations in design and technology of heavy-duty sandwich presses have transformed them from simple kitchen gadgets into versatile and efficient cooking tools. From adjustable pressure systems to smart technology, these appliances continue to evolve, offering users a wide range of features that enhance their cooking experience.

In recent years, the kitchen appliances market has witnessed a significant shift in consumer preferences, with sandwich presses emerging as a favorite among home chefs. These appliances are not just for the weekend bakers or the avid sandwich enthusiasts; they’ve become a staple in many modern kitchens. Let’s delve into the trends and preferences shaping the market for heavy-duty sandwich presses.

The Shift Towards ConvenienceConsumers today are increasingly looking for convenience in their kitchen appliances. The demand for quick and easy meal preparation has led to a surge in interest for sandwich presses. These devices offer a simple solution to crafting delicious sandwiches in minutes, without the need for additional cooking or heating equipment.

Versatility in FunctionalityOne of the key trends in the sandwich press market is the quest for versatility. Modern consumers are not satisfied with a one-trick pony; they seek appliances that can do more. Heavy-duty sandwich presses often come with multiple settings, allowing users to toast, grill, or press a variety of food items, from sandwiches to vegetables and even tofu.

Design and AestheticsThe aesthetics of kitchen appliances have become a significant factor in consumer purchasing decisions. Sandwich presses are no exception. Design has evolved from the traditional black or silver models to sleek, colorful, and modern designs that complement contemporary kitchen interiors. The integration of stylish elements such as LED displays and non-slip feet has also caught the eye of many.

Health and WellnessThere’s a growing awareness of health and wellness among consumers, and this extends to the appliances they choose for their kitchens. The popularity of sandwich presses that offer healthier options, such as those that allow for the cooking of sandwiches with less oil or those that can be used to grill vegetables, reflects this trend. Consumers are looking for appliances that not only make food tasty but also nutritious.

Safety FeaturesSafety has always been a concern, but it’s become even more paramount with the rise of single-parent households and busy professionals. Modern sandwich presses come with a range of safety features, including automatic shut-offs, cool-touch exteriors, and easy-to-clean surfaces. These features not only protect users but also make maintenance and cleaning more convenient.

Smart Technology IntegrationThe integration of smart technology into kitchen appliances is another trend that’s catching on. While not yet mainstream in the sandwich press category, there are models that can be controlled via smartphone apps or voice assistants. This allows users to start their sandwich pressing from a distance, or even to program their sandwich press for specific times, ensuring that their meal is ready when they need it.

Eco-Friendly and Sustainable MaterialsThe environmental impact of products is a major consideration for many consumers. Sandwich presses made from sustainable materials and with an emphasis on reducing energy consumption are gaining popularity. The market is seeing a trend towards appliances that are not only durable but also environmentally responsible.

Customization and PersonalizationTailoring appliances to individual preferences is becoming more common. Some manufacturers are offering sandwich presses with customizable heating elements, allowing users to adjust the temperature for different types of bread or fillings. This level of personalization is resonating with consumers who want to have more control over their cooking experience.

Global InfluencesThe sandwich press market is also influenced by global culinary trends. As people become more exposed to different cultures and their foods, there’s an increased interest in international sandwich variations. This has spurred the development of sandwich presses that can accommodate different bread types, fillings, and cooking styles, from classic American sandwiches to European-style paninis.

Retail and Online SalesLastly, the way consumers purchase kitchen appliances is changing. While brick-and-mortar stores still play a significant role, there’s a growing trend towards online sales. Consumers are seeking out the latest models and innovations on e-commerce platforms, and this has led to increased competition and innovation among manufacturers to capture the online market share.

In summary, the market for heavy-duty sandwich presses is evolving to meet the demands of a modern consumer base that values convenience, versatility, design, health, safety, smart technology, sustainability, customization, global culinary influences, and the ease of online shopping. As these trends continue to shape the market, we can expect to see further advancements and a greater variety of options for sandwich lovers everywhere.

In the competitive world of kitchen appliances, the sandwich press has emerged as a staple in many homes. Ensuring that these appliances meet high standards of quality is paramount. Quality control in sandwich press production is not just about meeting safety regulations; it’s about crafting a product that stands the test of time and satisfies the discerning consumer. Here’s a look into why quality control is so crucial in this process.

The precision of the components is key. Each part of a sandwich press, from the non-stick surfaces to the heating elements, must be meticulously crafted to ensure it functions flawlessly. A flawed component can lead to uneven cooking, damage to the appliance, or even pose a safety hazard. Quality control teams meticulously inspect every piece to guarantee that they are up to the task.

Durability is another critical factor. Sandwich presses are often subjected to high heat and pressure, and they need to withstand repeated use without failing. Quality control involves rigorous testing to ensure that the materials used can handle the demands placed on them. This includes drop tests, stress tests, and longevity assessments to ensure that the press can endure the rigors of daily use.

Safety is non-negotiable. In the kitchen, appliances are a constant presence, and the potential for accidents is ever-present. Quality control measures include thorough safety checks to ensure that the sandwich press has no sharp edges, that the heating elements are secure and insulated, and that there are no loose parts that could cause harm. These checks are essential to prevent any incidents that could lead to injury or damage.

Functionality is at the heart of a good sandwich press. Quality control involves testing the press’s ability to cook sandwiches evenly, with the right amount of heat and pressure. This means checking that the plates are properly aligned, that the heat distribution is even, and that the press can handle different types of bread without sticking or burning. Consistency in performance is vital, and quality control ensures that every sandwich press meets these standards.

Innovation is a driving force in the appliance industry, and sandwich presses are no exception. Quality control teams must also assess the integration of new features and technologies. Whether it’s a digital temperature control system or a unique design that enhances the cooking experience, these innovations must be tested to ensure they work seamlessly and do not compromise the overall quality of the product.

Environmental considerations are increasingly important. Quality control in sandwich press production includes evaluating the environmental impact of the materials and manufacturing processes. This involves selecting materials that are recyclable or biodegradable and ensuring that the manufacturing process is energy-efficient and waste-reducing.

Consumer satisfaction is the ultimate goal. Quality control in sandwich press production involves gathering feedback from users to understand their needs and expectations. This feedback is used to refine the product, ensuring that it not only meets but exceeds consumer expectations. The process includes analyzing customer complaints, conducting surveys, and implementing improvements based on user experiences.

Regulatory compliance is a must. Sandwich presses must adhere to a variety of safety and quality standards set by regulatory bodies. Quality control ensures that every aspect of the production process complies with these regulations, from the design and materials used to the final assembly and packaging.

In conclusion, the importance of quality control in sandwich press production cannot be overstated. It’s about ensuring that every press that leaves the factory is a reliable, safe, and enjoyable appliance for the consumer. From the smallest detail to the largest component, quality control is the silent guardian of the sandwich press’s reputation and the consumer’s satisfaction.

In the competitive world of kitchen appliances, a few heavy-duty sandwich press brands have managed to stand out, capturing the hearts and tastes of consumers. Let’s delve into the stories of a few successful heavy-duty sandwich press brands and what makes them tick.

These brands often share a common thread: a commitment to quality, innovation, and meeting the evolving demands of the market. One such brand is “GrillGuru,” known for its robust and reliable sandwich presses. GrillGuru’s success can be attributed to their focus on craftsmanship and material selection.

GrillGuru’s presses are crafted with high-quality stainless steel, ensuring durability and longevity. The brand has also introduced features like adjustable heat settings and non-stick surfaces, making it easier for users to achieve perfect sandwiches every time. Their marketing strategy revolves around the idea of convenience and gourmet taste at home, appealing to busy professionals and food enthusiasts alike.

Another standout brand is “SandwichMaster,” which has carved a niche for itself by offering a range of sandwich presses designed for different types of bread and fillings. SandwichMaster’s presses come with various press plates, allowing users to customize their sandwiches according to their preferences. The brand’s innovation doesn’t stop there; they’ve also developed a line of presses that can be used for cooking not just sandwiches but also paninis, wraps, and even grilled cheese.

One of the reasons for SandwichMaster’s success is their customer-centric approach. They conduct extensive market research to understand consumer needs and incorporate these insights into their product development. Their commitment to providing a seamless user experience has garnered a loyal customer base.

“PaniniPro” is another heavy-duty sandwich press brand that has made a name for itself in the industry. What sets PaniniPro apart is its sleek design and advanced technology. Their presses are not only built to last but also to impress with their modern aesthetics. The brand has integrated features like temperature control and a quick heat-up function, making it a favorite among those who appreciate both form and function.

PaniniPro’s success can also be attributed to their strategic partnerships with local bakeries and cafes, where their sandwich presses are used to create mouth-watering sandwiches for customers. This not only enhances their brand visibility but also reinforces their reputation for producing high-quality appliances.

“ClassicGrill” is a brand that has managed to maintain its traditional values while embracing modern technology. Their heavy-duty sandwich presses are a testament to their dedication to quality and craftsmanship. ClassicGrill’s presses are often seen in professional kitchens, where their robust build and consistent performance are highly valued.

The brand’s marketing strategy focuses on the timeless appeal of their products, emphasizing the joy of creating homemade sandwiches. ClassicGrill’s success story is a blend of old-world charm and new-world innovation, making them a go-to choice for those who appreciate the art of sandwich making.

“GrillGourmet” is a relatively new entrant in the market but has quickly gained traction with its unique approach to sandwich presses. The brand has introduced a range of eco-friendly sandwich presses made from recycled materials, appealing to environmentally conscious consumers. GrillGourmet’s commitment to sustainability has not compromised on quality, as their presses are just as durable and efficient as those from their competitors.

The brand’s marketing efforts highlight the importance of reducing one’s carbon footprint while enjoying delicious sandwiches. GrillGourmet’s innovative approach has not only captured the attention of eco-friendly consumers but has also sparked a conversation about sustainability in the kitchen appliance industry.

In conclusion, the success of these heavy-duty sandwich press brands can be attributed to their focus on quality, innovation, and understanding the needs of their customers. By continuously evolving their products and marketing strategies, these brands have managed to carve out a niche for themselves in a highly competitive market. Whether it’s through traditional craftsmanship, modern technology, or a commitment to sustainability, these brands have proven that a great sandwich press can be more than just a kitchen appliance—it can be a symbol of culinary excellence and innovation.

The evolution of sandwich presses has seen a remarkable transformation, from the humble days of simple flat irons to the sophisticated, heavy-duty models that grace modern kitchens today. As consumer tastes and lifestyles shift, so too does the technology and design of these kitchen appliances. Let’s delve into the future of sandwich presses, exploring the predictions and opportunities that lie ahead.

The rise of convenience cooking has fueled the demand for efficient and easy-to-use appliances. Sandwich presses, with their ability to deliver restaurant-quality sandwiches at home, have become a staple in many kitchens. The future of these appliances seems to be bright, with several key trends shaping the landscape.

One significant trend is the integration of smart technology. Modern sandwich presses are not just for toasting bread; they are becoming multi-functional devices that can cater to a variety of cooking needs. Imagine a sandwich press that can not only toast and grill but also bake or steam, all with the touch of a button. Smart features like temperature control, timer settings, and even Bluetooth connectivity to your smartphone for custom recipes are becoming increasingly common.

Another trend is the emphasis on health and wellness. As consumers become more health-conscious, there’s a growing interest in at-home cooking that allows for greater control over ingredients and preparation methods. Heavy-duty sandwich presses that offer adjustable heat settings and non-stick surfaces make it easier to prepare healthy, homemade sandwiches without the need for excessive oil or butter.

The customization of food is also a key factor in the future of sandwich presses. With the rise of niche markets and the demand for unique culinary experiences, manufacturers are responding by creating presses that can handle a variety of bread types, from artisanal loaves to gluten-free options. Some presses even come with interchangeable plates for different cooking styles, such as panini or ciabatta.

The opportunity for innovation in design is vast. There’s a clear trend towards compact, space-saving appliances that can fit into smaller kitchens or be easily stored away. Modern sandwich presses are also incorporating sleeker, more stylish designs that appeal to the aesthetic sensibilities of contemporary cooks.

The market for sandwich presses is also expanding globally. As people travel more and expose themselves to different cuisines, there’s a desire to bring those flavors home. This has led to the development of presses that can replicate the flavors of international sandwiches, from Italian paninis to Japanese okonomiyaki.

From a business perspective, the opportunity lies in catering to these evolving consumer needs. Companies that can adapt and offer innovative solutions will likely see growth. This could mean anything from developing presses that are compatible with sous-vide cooking techniques to those that are designed for use in commercial settings, like food trucks or pop-up restaurants.

One of the most exciting opportunities is the potential for sustainability. As environmental concerns grow, there’s a push for products that are eco-friendly. This could involve using recycled materials in the manufacturing process, creating appliances that are energy-efficient, or designing presses that are easy to repair and upgrade.

In terms of market trends, the rise of e-commerce has opened up new avenues for sandwich press manufacturers. Online sales have become a significant part of the market, and brands that excel in digital marketing and customer service can gain a competitive edge.

When looking at successful heavy-duty sandwich press brands, it’s clear that those who have embraced these trends are reaping the benefits. They’ve managed to create a loyal customer base by offering quality products that not only meet but exceed consumer expectations.

In conclusion, the future of sandwich presses is one of innovation, sustainability, and global appeal. The key to success will be for manufacturers to stay attuned to the changing needs of consumers and to be willing to invest in research and development to bring new and exciting products to market. The opportunities are vast, and those who navigate the evolving landscape effectively will undoubtedly find success.

The evolution of kitchen appliances has brought about a revolution in culinary experiences, and the heavy-duty sandwich press stands as a testament to this transformation. These appliances have not only become a staple in many homes but have also redefined the way we enjoy our favorite sandwiches. In this conclusion, we delve into why heavy-duty sandwich presses are a game-changer in the kitchen appliances market.

The compact nature of sandwich presses allows for a quick and convenient way to prepare a meal, perfect for busy lifestyles or those who simply appreciate a good sandwich. These devices have transcended their original purpose, becoming a symbol of culinary innovation and a must-have for any kitchen enthusiast.

One of the key reasons for the surge in popularity of heavy-duty sandwich presses is their versatility. They can handle a wide variety of bread types, from thick, artisanal loaves to delicate wraps and buns. This adaptability means that users can experiment with different fillings and toppings, creating unique and personalized sandwich experiences.

Moreover, the design of these presses has evolved to cater to modern tastes. With sleek, modern aesthetics and user-friendly features, they have become a stylish addition to any kitchen countertop. The inclusion of non-stick surfaces and adjustable heat settings ensures that every sandwich is cooked to perfection, with a golden-brown crust and a tender, juicy interior.

In terms of functionality, heavy-duty sandwich presses often come with additional features that enhance the cooking process. Some models include indicator lights to signal when the press is ready to use, while others offer adjustable pressure controls for different types of bread. These features not only make the cooking process more intuitive but also ensure that the end result is consistently delicious.

The rise of health-conscious consumers has also played a significant role in the success of heavy-duty sandwich presses. As people seek out healthier alternatives to fast food and processed snacks, these appliances offer a way to enjoy a freshly prepared meal at home. The ability to control the ingredients and cooking methods means that users can create sandwiches that are not only satisfying but also nutritious.

When it comes to the market, heavy-duty sandwich presses have seen a surge in demand. Online marketplaces and specialty kitchen stores are brimming with options, catering to a wide range of budgets and preferences. The growth of social media has also played a part in this trend, with influencers and home cooks showcasing their creations, sparking a wave of interest in homemade sandwiches.

In the realm of sustainability, heavy-duty sandwich presses are making waves. Many modern models are designed with eco-friendly materials and energy-efficient features, appealing to consumers who are increasingly concerned about their environmental footprint. This shift towards sustainability is not only beneficial for the planet but also for the wallets of consumers, as these appliances can reduce energy consumption.

Case studies of successful heavy-duty sandwich press brands reveal a consistent focus on innovation and customer satisfaction. Companies like George Foreman and Breville have become synonymous with quality and reliability, offering a range of models that cater to different needs and tastes. Their commitment to research and development has led to the creation of cutting-edge appliances that push the boundaries of what a sandwich press can do.

Looking ahead, the future of sandwich presses looks bright. As technology continues to advance, we can expect to see even more innovative features and designs. Smart sandwich presses that can be controlled via smartphone apps, for example, are not far-fetched. These devices could offer personalized cooking programs, nutritional information, and even social sharing capabilities.

The opportunities for growth in the heavy-duty sandwich press market are vast. As the world becomes more health-conscious and time-poor, the demand for quick, convenient, and delicious meals at home will only increase. The sandwich press, with its ability to deliver a gourmet-quality sandwich in minutes, is perfectly positioned to capitalize on this trend.

In conclusion, heavy-duty sandwich presses have become a game-changer in the kitchen appliances market. Their versatility, design, functionality, and health benefits have made them a staple in many homes. As the market continues to evolve, these appliances are poised to become even more integral to our daily lives, offering a simple yet effective solution to the age-old question of what to eat for lunch.