Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In a world where convenience meets culinary delight, the sandwich grill plant industry has seen a surge in innovation and efficiency. As these specialized facilities churn out perfectly toasted sandwiches with precision and speed, we delve into the intricacies of their continuous operation, uncovering the key features that define modern sandwich grill plants, and exploring the evolving market trends and consumer preferences that drive this dynamic sector. With a focus on data-driven insights and real-world case studies, we also examine the challenges faced by the industry and the creative solutions being implemented to meet the demands of a fast-paced, ever-changing market. As we gaze into the horizon, we envision the future outlook for continuous operation sandwich grill plants, poised to shape the way we savor our favorite sandwiches.

The continuous operation sandwich grill plant has emerged as a game-changer in the culinary landscape, transforming the way we enjoy our favorite sandwiches. These specialized facilities are designed for non-stop production, ensuring a steady stream of freshly grilled sandwiches to satisfy the cravings of sandwich enthusiasts. The rise of these plants can be attributed to several key factors that have reshaped the kitchen appliances industry.

The demand for convenience has soared, with busy consumers seeking quick and delicious meals. Continuous operation sandwich grill plants cater to this need, providing a streamlined process that guarantees sandwiches are ready at a moment’s notice.

Technological advancements have made it possible to maintain consistent quality and temperature throughout the grilling process. Advanced sensors and control systems ensure that each sandwich is cooked to perfection, with minimal waste and maximum output.

The rise of foodservice franchises has created a market where speed and efficiency are paramount. Continuous operation plants can supply multiple outlets simultaneously, keeping the franchisees’ operations running smoothly and meeting customer expectations.

The ability to customize sandwiches has become a staple in modern dining. Continuous operation sandwich grill plants often come equipped with modular systems that allow for quick changes in menu options, accommodating different flavors and dietary preferences.

The integration of these plants into larger food production facilities has streamlined the supply chain. By integrating sandwich production with other food processing units, these plants contribute to a more efficient and cohesive food manufacturing process.

Energy efficiency has become a crucial concern in the food industry. Continuous operation sandwich grill plants are designed with energy-saving technologies in mind, reducing the overall carbon footprint and operating costs.

The investment in these plants is justified by the long-term cost savings. Although the initial setup costs can be significant, the continuous operation model allows for a steady return on investment due to increased production volume and reduced labor needs.

The global trend towards healthy eating has also played a role in the popularity of continuous operation sandwich grill plants. These facilities can produce sandwiches with a variety of healthy ingredients, appealing to health-conscious consumers.

The adaptability of these plants to different environments is another factor in their rise. Whether installed in bustling city centers, shopping malls, or busy airports, these plants can operate effectively, contributing to the convenience culture that thrives in today’s fast-paced world.

The ability to maintain a consistent brand identity across multiple locations is essential for foodservice businesses. Continuous operation sandwich grill plants ensure that every sandwich served meets the brand’s quality standards, regardless of where the customer is located.

The integration of these plants with e-commerce platforms has opened up new distribution channels. Customers can now enjoy their favorite grilled sandwiches delivered right to their doorstep, thanks to the efficient production capabilities of these plants.

The competitive nature of the food industry has pushed companies to innovate and differentiate their offerings. Continuous operation sandwich grill plants allow businesses to introduce new products and promotions quickly, staying ahead of the competition.

The success of these plants has also been fueled by a skilled workforce that understands the intricacies of sandwich production. Training programs and continuous education ensure that employees are adept at handling the advanced machinery and maintaining high production standards.

The sustainability aspect of these plants cannot be overlooked. By reducing the need for raw materials and minimizing waste, these plants contribute to a more eco-friendly approach to food production.

The rise of continuous operation sandwich grill plants is a testament to the industry’s ability to evolve and adapt to changing consumer needs. As the market continues to grow, these plants will likely become even more prevalent, shaping the future of the sandwich industry.

In the ever-evolving landscape of the kitchen appliances industry, understanding the market dynamics is crucial for both manufacturers and consumers. The industry is marked by rapid technological advancements, shifting consumer preferences, and intense competition. Here’s a closer look at the key aspects shaping this dynamic sector.

Consumer Trends Shift RapidlyConsumer demands are constantly evolving, driven by factors such as health consciousness, convenience, and technological innovation. For instance, there’s a growing preference for smart kitchen appliances that offer connectivity and remote control capabilities. This shift has led to a surge in products like smart ovens, refrigerators with built-in cameras, and countertop mixers with recipe apps.

Market Segmentation by Product TypeThe kitchen appliances market is segmented by product type, with categories like cooking appliances, refrigeration, dishwashing, and small kitchen appliances. Cooking appliances, including ranges, ovens, and countertop grills, have seen a steady increase in demand due to the popularity of home cooking and baking. Meanwhile, refrigeration units are becoming more energy-efficient and feature-packed, catering to consumers looking for both sustainability and convenience.

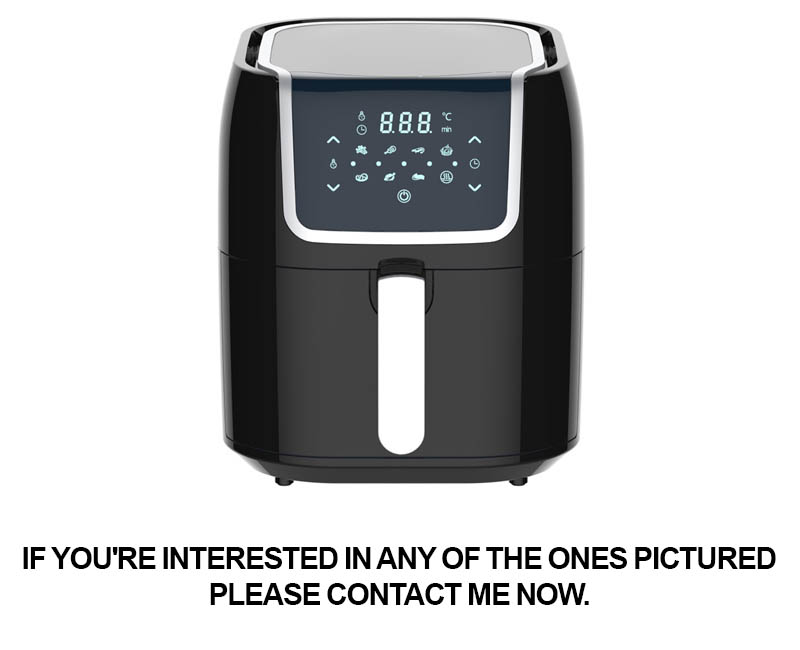

Innovation and Technological IntegrationInnovation is a cornerstone of the kitchen appliances industry. Companies are continuously pushing the boundaries with features like self-cleaning ovens, induction cooktops that save energy, and air fryers that offer healthier cooking options. The integration of technology, such as voice assistants and IoT (Internet of Things), is also becoming more prevalent, allowing appliances to be controlled through smartphones and other smart devices.

Globalization and Supply Chain ComplexityGlobalization has had a significant impact on the kitchen appliances industry. Manufacturers source components from various countries, which can lead to complex supply chains. This interconnectedness can bring benefits like cost savings and access to a wider range of materials, but it also makes the industry vulnerable to geopolitical events and trade disputes.

Regulatory Environment and ComplianceThe kitchen appliances industry is heavily regulated, with standards and certifications that manufacturers must adhere to. Energy efficiency regulations, for example, have led to the development of more eco-friendly appliances. Compliance with these standards can be challenging, especially for companies that operate in multiple regions with differing regulations.

E-commerce and Direct-to-Consumer ModelsThe rise of e-commerce has transformed the way consumers purchase kitchen appliances. Online platforms offer a wider selection and often more competitive pricing. Some companies have even adopted direct-to-consumer (DTC) models, cutting out the middleman and providing a more personalized shopping experience. This shift has also led to an increase in customer reviews and social media influence on purchasing decisions.

Competitive Landscape and Brand LoyaltyThe competitive landscape in the kitchen appliances industry is fierce, with established brands vying for market share against both traditional players and emerging startups. Brand loyalty plays a crucial role, as consumers tend to stick with brands they trust for quality and reliability. Companies are investing in marketing and brand building to maintain their position in a crowded market.

Sustainability and Corporate Social ResponsibilitySustainability is a growing concern for consumers and businesses alike. Kitchen appliance manufacturers are increasingly focusing on sustainable practices, from designing energy-efficient products to using recycled materials. Corporate social responsibility (CSR) initiatives are also becoming more common, as companies aim to demonstrate their commitment to environmental and social issues.

Market Entry and Expansion ChallengesEntering new markets can be challenging for kitchen appliance manufacturers. Cultural differences, local regulations, and distribution networks must all be considered. Expansion into emerging markets, where the middle class is growing, offers opportunities for growth but also presents unique challenges in terms of infrastructure and consumer behavior.

The Importance of After-Sales ServiceThe customer experience doesn’t end with the purchase of a kitchen appliance. After-sales service is crucial for maintaining customer satisfaction and brand reputation. Companies are investing in training service technicians, expanding service networks, and offering extended warranties to ensure customers have a positive experience throughout the product lifecycle.

In conclusion, the kitchen appliances industry is a dynamic and complex sector, influenced by a multitude of factors. Understanding these market dynamics is essential for anyone looking to navigate this ever-changing landscape successfully.

Grill technology has come a long way from the classic sandwich presses to the sophisticated, high-tech sandwich grills we see today. The evolution of sandwich grill technology has been marked by a series of innovations that have transformed the way we enjoy our meals. Here’s a look at some of the most notable advancements:

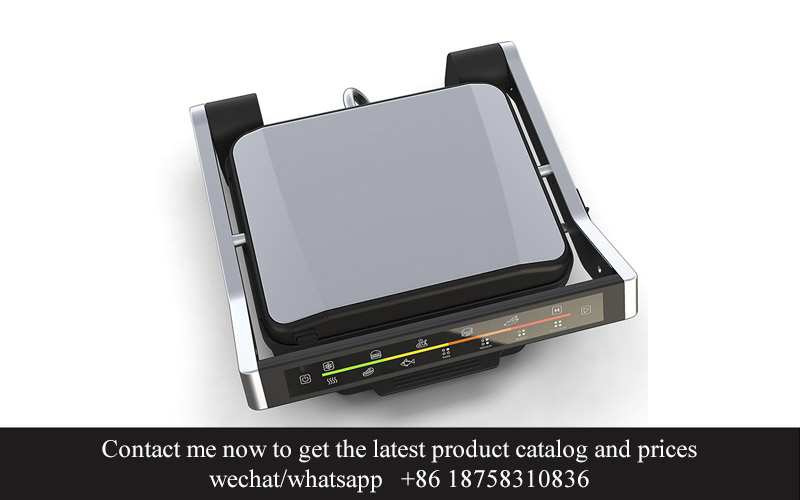

Temperature Control Advancements: Early sandwich grills relied on a simple heating element to cook the bread, but modern grills now offer precise temperature control. Smart sensors and digital interfaces allow users to set exact temperatures for different types of bread and fillings, ensuring that each sandwich is cooked to perfection.

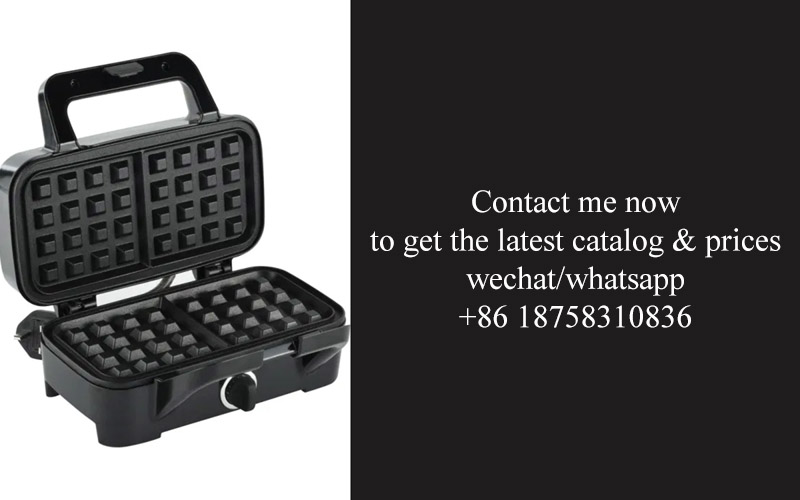

Non-Stick Surfaces: The non-stick surface was a game-changer for sandwich grills. It eliminated the need for butter or oil, reducing the amount of fat in the sandwich and making cleanup easier. Newer coatings are even more durable and release food more efficiently, keeping the sandwiches from sticking.

Multiple Grilling Plates: Traditional sandwich grills had a single plate for cooking. However, innovations in design now include grilling plates that can cook multiple sandwiches simultaneously. This feature is particularly popular in commercial settings, where speed and efficiency are key.

Variable Heat Zones: Some high-end models now come with multiple heat zones, allowing users to cook different parts of the sandwich at different temperatures. This means the bread can be toasted to the desired crispness while the fillings remain juicy and warm.

Automated Open/Close Mechanisms: A common frustration with manual sandwich presses is the difficulty of opening them after cooking. Innovations in sandwich grill technology now include automatic open and close mechanisms, which not only make it easier to access the sandwich but also improve safety by reducing the risk of burns.

LED Lighting: Modern sandwich grills often come with built-in LED lighting. This feature not only illuminates the cooking surface but also adds a sleek, modern aesthetic to the appliance. It’s particularly useful for showing off the details of the sandwich being prepared.

Integrated Food Warmers: Some advanced sandwich grills include a warming tray that keeps the sandwich warm until it’s ready to be served. This is especially convenient for busy households or restaurants looking to maintain the temperature of their sandwiches.

Programmable Settings: For those who want complete control over their sandwich preparation, programmable settings have become increasingly common. Users can set the grill to their preferred cooking times and temperatures, ensuring consistency every time.

Safety Features: Safety has always been a concern with cooking appliances, and sandwich grills are no exception. Newer models include features like cool-touch handles, auto shut-off mechanisms, and overload protection to prevent accidents and damage to the appliance.

Portability: While commercial sandwich grills are typically large and fixed, there has been a push towards portable, compact models for home use. These portable grills are great for picnics, camping, or anyone who wants to enjoy a freshly grilled sandwich on the go.

Customizable Grilling Patterns: Some advanced sandwich grills now offer the ability to customize the grill pattern, which can leave a distinctive texture on the sandwich. This feature allows for personalization and can even be a fun addition for kids.

Energy Efficiency: As environmental concerns grow, energy efficiency has become a crucial factor in appliance design. Modern sandwich grills are designed to use less energy while still providing high-performance cooking capabilities.

These innovations in sandwich grill technology have not only made cooking sandwiches more convenient and efficient but have also added a level of sophistication to a once-simple kitchen staple. From the ease of use to the enhanced taste and presentation, these advancements continue to shape the way we enjoy our favorite comfort food.

In the ever-evolving kitchen appliances industry, the ability to maintain continuous operation is a game-changer for both manufacturers and end-users. This capability significantly impacts efficiency and productivity in several ways.

The seamless flow of production that continuous operation provides allows for uninterrupted service, which is particularly crucial during peak demand periods. For sandwich grill plants, this means they can meet the surge in orders without the downtime typically associated with manual shutdowns and maintenance. This constant workflow leads to a more predictable output, ensuring that customers receive their products on time.

Efficiency is also enhanced through reduced waste. Continuous operation minimizes the time spent on switching between different tasks or products, which can often lead to errors and scraps. With a non-stop process, sandwich grill plants can streamline their operations, focusing on precision and quality control. The result is a lower scrap rate and a more sustainable production cycle.

Productivity gains are substantial when considering the labor aspect. Employees can work in a more structured and consistent manner, which not only increases their own efficiency but also reduces the risk of fatigue-related mistakes. The repetitive nature of continuous operation can train workers to perform their tasks with greater speed and accuracy, translating into higher output levels without the need for additional staffing.

Energy consumption is another area where continuous operation shines. By keeping the equipment running, sandwich grill plants can optimize their energy use. This is especially true for high-powered equipment like sandwich grills, where starting up and shutting down can consume a significant amount of energy. Continuous operation ensures that energy is used efficiently throughout the production cycle, leading to cost savings and a smaller environmental footprint.

The precision and reliability of the equipment are also crucial in maintaining a continuous operation. Advanced control systems are often employed to monitor and adjust the process in real-time, ensuring that the sandwich grills run smoothly and consistently. These systems can detect anomalies early and alert operators to potential issues before they escalate, preventing costly downtime.

Furthermore, the use of predictive maintenance in continuous operation can prevent breakdowns before they occur. By analyzing data from the equipment’s performance, manufacturers can schedule maintenance proactively, ensuring that the sandwich grills are always in top condition. This approach not only minimizes the risk of unexpected stops but also extends the lifespan of the equipment.

In terms of scalability, continuous operation allows sandwich grill plants to easily adapt to changes in production volume. Whether it’s a gradual increase or a sudden surge, the non-stop nature of the process means that adjustments can be made without significant downtime. This flexibility is essential for businesses looking to grow and stay competitive in a fast-paced market.

The role of continuous operation in efficiency and productivity extends beyond the factory floor. It also impacts the logistics and distribution of finished products. With a constant flow of sandwiches being produced, distributors can plan their routes and schedules more effectively, ensuring that products reach retailers and consumers promptly.

Moreover, the reduction in labor requirements due to continuous operation can have a ripple effect on the overall cost structure of sandwich grill plants. With fewer workers needed to maintain a high output, companies can invest in training more skilled staff or even reassign resources to other areas of the business, leading to a more balanced and efficient operation.

In conclusion, continuous operation in sandwich grill technology is a cornerstone of modern production processes. It drives efficiency through waste reduction and optimized energy use, boosts productivity through streamlined labor and predictive maintenance, and provides the scalability needed to meet market demands. As the industry continues to innovate, the importance of continuous operation in achieving these goals is only set to grow.

Modern sandwich grill plants have evolved to incorporate a range of features that enhance their efficiency, productivity, and the quality of the sandwiches they produce. Here’s a detailed look at some of the key features that define these state-of-the-art facilities:

Efficient Heat Distribution SystemsGrill plants are equipped with advanced heat distribution systems that ensure uniform cooking across the surface of each sandwich. These systems, often featuring multiple heating elements, allow for precise temperature control, which is crucial for maintaining the integrity of ingredients like meat, cheese, and vegetables.

Automated Assembly LinesMany modern sandwich grill plants have automated assembly lines that streamline the production process. These lines can handle tasks such as bread loading, filling, and topping with precision, reducing the need for manual labor and minimizing the risk of errors.

Customizable Cooking SettingsTo cater to a variety of sandwich preferences, modern grill plants are equipped with cooking settings that can be adjusted to different temperatures and cooking times. This flexibility allows for the preparation of a wide range of sandwiches, from crispy to tender, with minimal adjustments.

High-Speed Grilling MechanismsGrill plants often feature high-speed grilling mechanisms that can cook a large number of sandwiches in a short period. These mechanisms are designed to maintain a consistent heat level, ensuring that every sandwich is cooked to perfection without any burn or undercooked spots.

Robust Material HandlingEfficient material handling is a cornerstone of modern sandwich grill plants. This includes the use of conveyer belts, robotic arms, and other automation tools that can move ingredients and sandwiches through the production line quickly and safely.

Hygiene and CleanabilityWith health and safety being paramount in the food industry, modern grill plants prioritize hygiene. They are designed with easy-to-clean surfaces, stainless steel construction, and integrated cleaning systems that allow for thorough sanitization between batches.

Modular Design for ScalabilityThe modular design of modern sandwich grill plants allows for scalability. As demand grows, additional modules can be added to the existing plant, ensuring that the production capacity can be expanded without significant disruptions or costly rebuilds.

Smart Sensors and ControlsSmart sensors and controls are integrated into the heart of these plants, providing real-time data on the cooking process. This data helps in optimizing cooking times, adjusting heat settings, and monitoring energy consumption, all of which contribute to overall efficiency.

Sustainable Energy SolutionsModern sandwich grill plants are increasingly adopting sustainable energy solutions. This can include solar panels for renewable energy, energy-efficient lighting, and advanced insulation to reduce the overall carbon footprint of the facility.

Noise and Heat ReductionEfforts are made to reduce the noise and heat generated during the cooking process. This is particularly important in high-traffic areas and urban locations. Advanced ventilation systems and noise-dampening materials are used to keep the work environment comfortable and compliant with local regulations.

Quality Assurance SystemsQuality control is non-negotiable in the food industry. Modern sandwich grill plants incorporate rigorous quality assurance systems, including automated checks for ingredients, cooking temperatures, and final product inspection to ensure consistency and safety.

In summary, the key features of modern sandwich grill plants reflect a commitment to efficiency, productivity, and quality. By leveraging technology and innovation, these plants are able to produce a high volume of top-quality sandwiches while maintaining a safe, hygienic, and sustainable production environment.

In the evolving landscape of the kitchen appliances industry, understanding market trends and consumer preferences is paramount. The sandwich grill market, in particular, has seen a surge in demand driven by several factors. Here’s a glimpse into the trends and preferences shaping this sector.

The growing health consciousness among consumers has led to a preference for healthier cooking methods. Sandwich grills, with their ability to cook food with minimal oil, have become a popular choice. Consumers are seeking appliances that not only simplify meal preparation but also offer health benefits.

Smart technology integration is becoming a staple in modern kitchen appliances. Smart sandwich grills that can be controlled via smartphones or other devices offer convenience and connectivity. Users can pre-set cooking times and temperatures, ensuring consistent results every time.

Versatility is another key feature that consumers are looking for. Modern sandwich grill plants are producing models that can handle a variety of food items, from classic sandwiches to wraps and even vegetables. This adaptability makes these appliances a versatile addition to any kitchen.

Eco-friendly and sustainable materials are gaining traction in the market. Consumers are increasingly concerned about the environmental impact of their purchases, and sandwich grill manufacturers are responding by using recycled materials and energy-efficient designs.

There’s a noticeable shift towards compact and space-saving designs. As urban living spaces become smaller, consumers are gravitating towards appliances that can be easily stored or integrated into smaller kitchens. Compact sandwich grills are becoming more popular, offering a practical solution for those with limited space.

The demand for customization and personalization is on the rise. Consumers are not just looking for appliances that do the job; they want something that reflects their personal style. Sandwich grill plants are introducing a range of colors, designs, and even customizable cooking plates to cater to this trend.

Health and safety features are also a priority. Modern sandwich grills come with non-stick surfaces that reduce the need for grease, safety locks to prevent accidental burns, and temperature control systems to avoid overcooking. These features not only enhance the user experience but also contribute to a safer kitchen environment.

The trend towards meal prep and batch cooking is influencing the sandwich grill market. Many consumers are looking for appliances that can handle large quantities of food at once, making them ideal for preparing meals for the entire family or for batch cooking sessions.

Sustainability is not just about the materials used; it’s also about the lifecycle of the product. Consumers are interested in appliances that can be easily repaired or recycled at the end of their useful life. This focus on sustainability is prompting sandwich grill manufacturers to design products with longevity in mind.

In terms of consumer preferences, there’s a clear preference for ease of use. The simpler an appliance is to operate, the more likely it is to find a place in a consumer’s kitchen. Sandwich grills that offer intuitive controls and easy-to-clean surfaces are more likely to be favored.

Lastly, the global trend towards convenience and on-the-go eating is pushing the demand for portable and travel-friendly sandwich grills. These compact appliances are designed for those who need a quick, healthy meal option while away from home.

The market trends and consumer preferences in the sandwich grill industry reflect a dynamic and evolving landscape. As the industry continues to innovate, it will be interesting to see how these trends and preferences shape the future of kitchen appliances.

In the realm of sandwich grill plants, data-driven insights have become invaluable in optimizing performance and making informed decisions. Here’s a closer look at how these insights are shaping the industry:

Grill Performance Metrics: Key indicators such as cooking time, energy consumption, and heat distribution are meticulously tracked. By analyzing these metrics, manufacturers can identify inefficiencies and areas for improvement. For instance, a longer cooking time might indicate a need for a new heat element or a recalibration of the grill’s settings.

Energy Efficiency Gains: Continuous operation sandwich grill plants are designed to minimize energy waste. Data analysis reveals that improvements in insulation and more efficient heating elements have significantly reduced energy consumption. This not only cuts costs but also aligns with the growing demand for eco-friendly kitchen appliances.

Maintenance Trends: Regular maintenance is crucial for the longevity and performance of sandwich grill plants. Data-driven insights help in predicting maintenance needs before they lead to downtime. By keeping a close eye on performance trends, plant operators can schedule maintenance proactively, ensuring minimal disruption to the production line.

Product Quality Control: Data analytics play a vital role in ensuring that every sandwich comes out perfectly grilled. By monitoring the consistency of cooking temperatures and times, manufacturers can guarantee product quality and reduce the likelihood of customer complaints.

Customer Feedback Integration: Incorporating customer feedback into the data-driven insights allows for a more holistic approach to plant performance. Understanding what consumers appreciate about the sandwiches produced by the grill plants helps in fine-tuning the machines for better taste and texture.

Real-time Monitoring: Modern sandwich grill plants are equipped with real-time monitoring systems that provide instant data on the grill’s operation. This allows for quick responses to any anomalies, such as temperature fluctuations or unexpected shutdowns, preventing potential issues from escalating.

Predictive Analytics: Advanced predictive analytics models are being used to forecast future trends in sandwich consumption, ingredient preferences, and even seasonal demand. This forward-looking approach helps plants to be more agile in adjusting their production to meet market demands.

Safety and Compliance: Data-driven insights are also instrumental in ensuring that sandwich grill plants comply with health and safety regulations. Regular analysis of operational data helps in identifying potential hazards and ensuring that safety protocols are followed.

Resource Allocation: With the help of data insights, plant managers can allocate resources more effectively. This includes optimizing the use of staff, ingredients, and equipment to ensure that the sandwich grill plants operate at peak efficiency.

Training and Development: Data-driven insights also inform training programs for plant staff. By identifying skill gaps and areas where employees can improve, plants can invest in targeted training to enhance overall performance.

In conclusion, the role of data-driven insights in sandwich grill plant performance is multifaceted. It encompasses everything from improving efficiency and productivity to ensuring product quality and safety. By harnessing the power of data, sandwich grill plants can stay ahead in a competitive market and meet the evolving demands of consumers.

In the bustling world of sandwich grills, there are a few standout plants that have mastered the art of continuous operation. Let’s delve into the stories of a few successful sandwich grill plants and what makes them tick.

A plant in Chicago, known for its high-output grills, has seen a remarkable transformation. Initially, it struggled with downtime and inefficiencies, leading to production bottlenecks. However, by implementing advanced technology and optimizing their workflow, they now operate around the clock with minimal disruptions. The key to their success lies in their ability to monitor and adjust their operations in real-time, ensuring consistent quality and output.

Another plant in Texas prides itself on its custom-built grills, which cater to a diverse range of sandwich styles. This plant has found that continuous operation is not just about running the machines 24⁄7; it’s about understanding the lifecycle of each piece of equipment. Regular maintenance, predictive analytics, and a deep understanding of the production cycle have allowed them to maintain peak performance without any significant downtime.

In California, a sandwich grill plant has embraced automation to achieve continuous operation. They’ve invested in robotic systems that not only grill the sandwiches but also package them with precision. This integration has led to a seamless production line that runs uninterrupted, meeting the demand for fast and fresh sandwiches.

A plant in New York, known for its artisanal approach, has managed to maintain a continuous operation while focusing on quality. They’ve achieved this by creating a hybrid system that combines human craftsmanship with automated processes. By carefully selecting the right balance, they’ve managed to keep the line moving without compromising on taste or quality.

These case studies highlight a few key factors that contribute to the success of continuous operation sandwich grill plants:

Predictive Maintenance: By using data analytics to predict potential equipment failures, these plants can schedule maintenance proactively, avoiding unexpected downtime.

Flexible Workflows: Adapting to changes in demand and menu items without halting operations is crucial. These plants have implemented flexible workflows that allow for quick adjustments without stopping the entire production line.

Employee Training: Skilled workers are the backbone of any continuous operation. These plants invest in extensive training programs to ensure their employees can handle the demands of a 24⁄7 production environment.

Quality Control: Despite the relentless pace, these plants prioritize quality control. They’ve developed systems that monitor and ensure that every sandwich meets their stringent standards.

Supply Chain Management: Ensuring a steady supply of raw materials and components is vital for continuous operation. These plants have optimized their supply chains to avoid stockouts and maintain a smooth flow of production.

Energy Efficiency: Continuous operation requires substantial energy, so these plants focus on energy-efficient technologies to reduce costs and their environmental footprint.

The success of these continuous operation sandwich grill plants serves as an inspiration for the industry. They demonstrate that it’s possible to maintain high output and quality while keeping the line moving. By analyzing these case studies, other plants can identify strategies and solutions that could work for their own operations, leading to improved efficiency and productivity in the sandwich grill industry.

In the ever-evolving kitchen appliances industry, challenges persist, but so do innovative solutions. From technological hurdles to market shifts, the industry faces a myriad of obstacles. Here’s a look at some of the key challenges and the creative approaches being taken to overcome them.

Manufacturers grapple with the need for continuous improvement in energy efficiency. The demand for eco-friendly appliances has surged, pushing companies to develop more sustainable solutions. This push for efficiency often requires significant investment in research and development, but the rewards can be substantial in terms of cost savings and environmental impact.

Consumer expectations are at an all-time high, with a growing number of consumers seeking out smart, connected kitchen appliances. However, integrating advanced technology without compromising on the core functionality of the appliances can be tricky. Brands are addressing this by creating intuitive interfaces and seamless integration with other smart home devices.

Quality control remains a critical challenge, especially as production scales up. Ensuring that each unit meets the stringent quality standards is essential for maintaining the brand’s reputation. Many companies are turning to automation and AI to monitor and optimize the manufacturing process, reducing errors and improving consistency.

Supply chain disruptions have become a frequent issue, impacting the ability to maintain inventory and meet customer demand. Companies are diversifying their supply chains to reduce reliance on a single source, and they’re also investing in inventory management systems to forecast demand more accurately and streamline logistics.

Regulatory compliance is another challenge that requires constant vigilance. Changes in safety standards and environmental regulations can lead to costly recalls or production delays. To stay ahead, manufacturers are staying abreast of legislative updates and investing in compliance training for their staff.

The rapid pace of technological advancements can be daunting. Keeping up with the latest innovations is crucial, but it also means that older models can quickly become obsolete. To tackle this, companies are adopting a culture of innovation, encouraging employees to experiment with new ideas and fostering a collaborative environment.

Labor issues also play a significant role in the industry. Ensuring safe working conditions, offering competitive wages, and providing opportunities for career growth are essential for maintaining a motivated workforce. Some companies are implementing wellness programs and investing in training to help employees develop new skills, which in turn boosts productivity.

The challenge of global expansion is also prevalent. Entering new markets requires a deep understanding of local regulations, consumer preferences, and cultural nuances. Companies are often hiring local experts or forming strategic partnerships to navigate these complexities successfully.

In response to these challenges, the industry is seeing a variety of solutions emerge. One of the most prominent is the use of cloud computing for data analytics, which allows for real-time monitoring and predictive maintenance, reducing downtime and improving efficiency.

Collaborative robotics, or cobots, are being integrated into manufacturing processes to work alongside human workers. This not only increases productivity but also enhances safety by reducing the risk of workplace accidents.

Customization is becoming a key differentiator in the market. By offering personalized products, manufacturers can cater to the unique needs of different consumer segments. This requires flexible production lines and advanced software to manage complex customization requests.

Sustainability initiatives are also gaining traction. Companies are investing in renewable energy sources, recycling programs, and sustainable materials to reduce their carbon footprint and appeal to environmentally conscious consumers.

Lastly, the industry is focusing on enhancing customer service through digital channels. By leveraging AI and machine learning, companies are providing more personalized support and efficient troubleshooting, which improves customer satisfaction and loyalty.

In summary, the kitchen appliances industry faces a multitude of challenges, but by embracing innovation, investing in technology, and prioritizing employee well-being, manufacturers are finding ways to not only overcome these obstacles but also thrive in an increasingly competitive and dynamic market.

In the ever-evolving landscape of the kitchen appliances industry, the continuous operation sandwich grill plant has emerged as a game-changer. These innovative facilities are not just revolutionizing the way sandwiches are prepared but also reshaping the entire market. The future outlook for these plants is bright, driven by technological advancements, consumer demands, and the quest for efficiency and productivity. Here’s a glimpse into the potential future of continuous operation sandwich grill plants.

The integration of smart technology has allowed these plants to streamline their operations, reducing downtime and increasing throughput. With automated systems managing the cooking process, these plants can operate 24⁄7 without the need for human intervention, ensuring a constant supply of freshly grilled sandwiches. This relentless operation is a testament to the plants’ reliability and efficiency.

Consumer preferences are shifting towards convenience and health. The continuous operation sandwich grill plants are capitalizing on this trend by offering a variety of sandwich options that cater to different dietary needs. From vegan to gluten-free, these plants are able to cater to a diverse clientele, thanks to their flexible and adaptable production lines.

The market for sandwich grill plants is witnessing a surge in demand. Supermarkets, food courts, and even mobile food vendors are increasingly incorporating these plants into their operations. The ability to produce high-quality sandwiches at scale has made these plants an attractive investment for businesses looking to enhance their menu offerings.

However, the future of continuous operation sandwich grill plants is not without its challenges. Energy consumption remains a significant concern, with the need for efficient and sustainable power sources becoming more pressing. Companies are investing in renewable energy solutions and energy-efficient technologies to mitigate this issue.

Another challenge is maintaining product quality and consistency over long periods of continuous operation. These plants must ensure that the high standards are maintained, which involves rigorous quality control measures and regular maintenance of equipment. The industry is responding by developing advanced monitoring systems that can predict and prevent potential issues before they arise.

The future of continuous operation sandwich grill plants also hinges on regulatory compliance. As the industry grows, so does the need for standardized protocols and safety regulations. Plants must adapt to these changing requirements to continue operating smoothly.

Despite these challenges, the industry is actively seeking solutions. One such solution is the use of modular design in sandwich grill plants. This approach allows for easy expansion and customization, ensuring that plants can evolve with the market. Modular designs also facilitate quick and cost-effective upgrades, keeping the plants at the forefront of technological advancements.

Another significant development is the integration of AI and machine learning. These technologies are being used to optimize production processes, predict demand, and even personalize sandwiches based on consumer preferences. The future plant may not just cook sandwiches but also learn from consumer behavior to create a more tailored experience.

The continuous operation sandwich grill plant is also poised to benefit from the rise of the internet of things (IoT). By connecting various systems and devices, these plants can achieve real-time data analytics, enabling better decision-making and predictive maintenance. This interconnectedness will further enhance efficiency and productivity.

In conclusion, the future of continuous operation sandwich grill plants is one of continuous improvement and innovation. As technology advances and consumer needs evolve, these plants will play a pivotal role in shaping the foodservice industry. With a focus on sustainability, quality, and consumer satisfaction, the future looks promising for these dynamic and efficient operations.