The UL 197 commercial preferred has emerged as a vital benchmark for kitchen equipment safety, using producers to prioritize product excellence. This stringent trendy ensures complete protection capabilities, which includes electrical, fabric, and structural integrity, as well as environmental issues like recyclability. by adhering to UL 197, producers beautify their products’ attraction, making them a preferred desire for clients seeking dependable and relaxed kitchen home equipment.

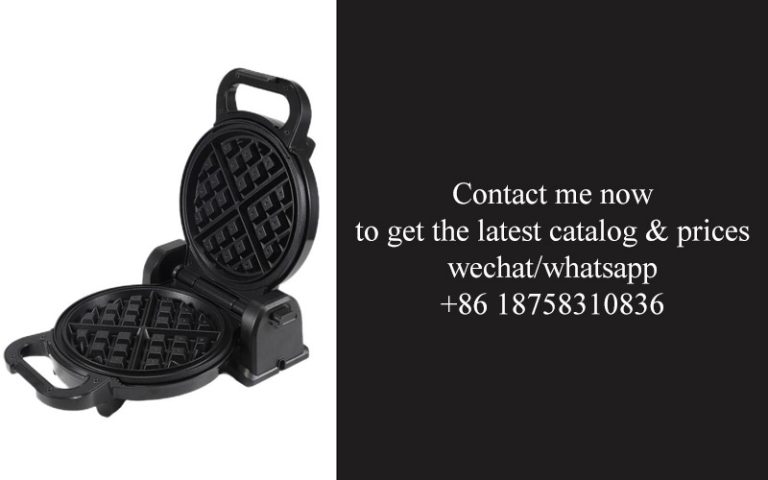

In Ningbo, the Waffle Iron market is prospering, driven by using growing consumer call for for kitchen appliances and a developing choice for a more fit lifestyle. neighborhood manufacturers are capitalizing in this trend, providing a diverse range of merchandise from conventional to clever, multifunctional models. The Ningbo Waffle Iron market is thought for its

craftsmanship and revolutionary designs, with products an increasing number of integrating clever era for handy cooking. as the market expands, Ningbo Waffle Iron producers are poised to capture both home and global opportunities, leveraging their popularity and technological improvements.

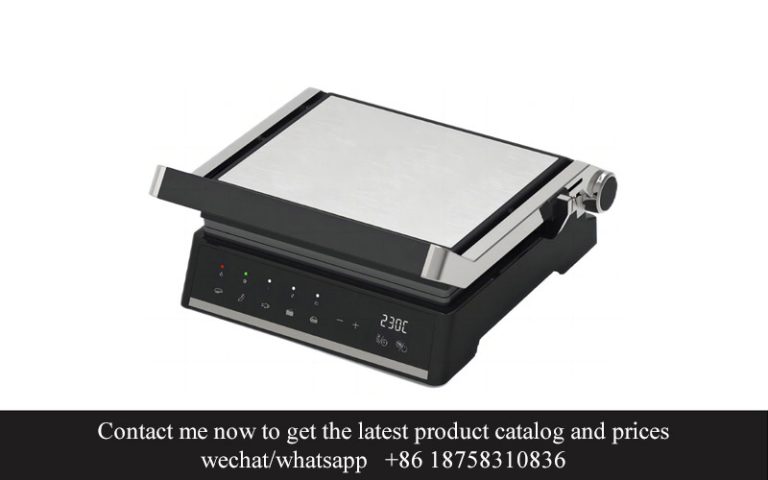

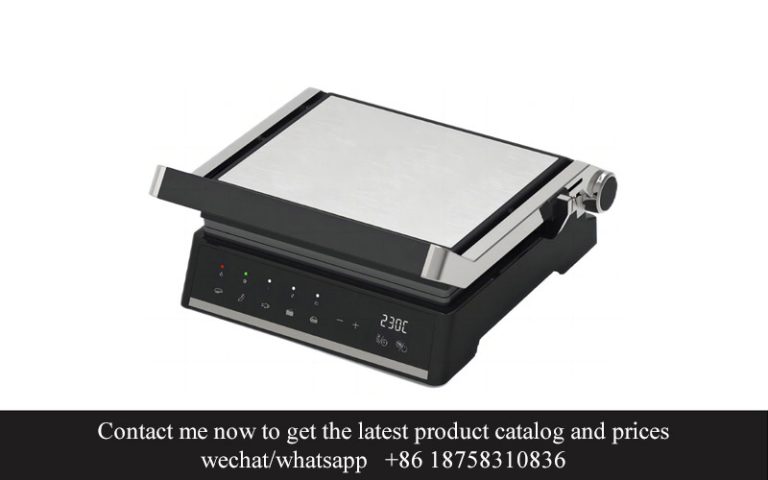

The CE-EN 60335 popular ensures the safety and performance of kitchen appliances just like the waffle baker. manufacturers need to adhere to this widespread, focusing on insulation, overheat safety, and mechanical energy necessities. As generation advances, innovations which include smart temperature control decorate product protection and capability. This, coupled with the growing call for for wholesome cooking solutions, drives the market’s continuous increase, emphasizing the importance of protection and health in equipment manufacturing.

With the rising emphasis on environmental safety, the RoHS three compliant heating machine has emerge as a giant thing in the kitchen equipment enterprise. This system, designed to satisfy stringent ecu Union requirements, makes use of

materials and efficient layout to ensure high overall performance and power conservation. As kitchen home equipment an increasing number of prioritize sustainability and performance, the adoption of RoHS three compliant heating structures is set to enhance average product nice and client satisfaction, fostering market growth and sure competitive gain.

With the worldwide kitchen appliance market’s relentless increase, OEM providers are increasingly more critical in industry innovation and catering to purchaser desires. Rotterdam, as a logistics hub and gateway to Europe, is a strategic location for plenty brands to companion with OEMs. The town’s green logistics, aggressive marketplace environment, and cognizance on

and smart merchandise make it a top vacation spot for OEMs. trends show a shift towards customized services, smart improvements, environmental sustainability, and global enlargement, with a developing emphasis on user revel in and move-industry integration. This synergy among region, marketplace traits, and progressive product design positions OEM carriers in the kitchen equipment industry for full-size increase and marketplace leadership.

The kitchen equipment market is presently witnessing a surge in innovation, with a developing call for for protection and functionality. The GOST R IEC 60335-2-nine certification has emerged as a essential gateway for producers to go into the Russian market. To be triumphant, organizations should integrate innovative products with this certification, ensuring compliance from layout to production. This not only guarantees product protection however additionally enhances brand recognition and market competitiveness. with the aid of adhering to the stringent necessities of the GOST R IEC 60335-2-9 trendy, producers can make sure their appliances aren’t only secure but also meet the evolving needs of customers.

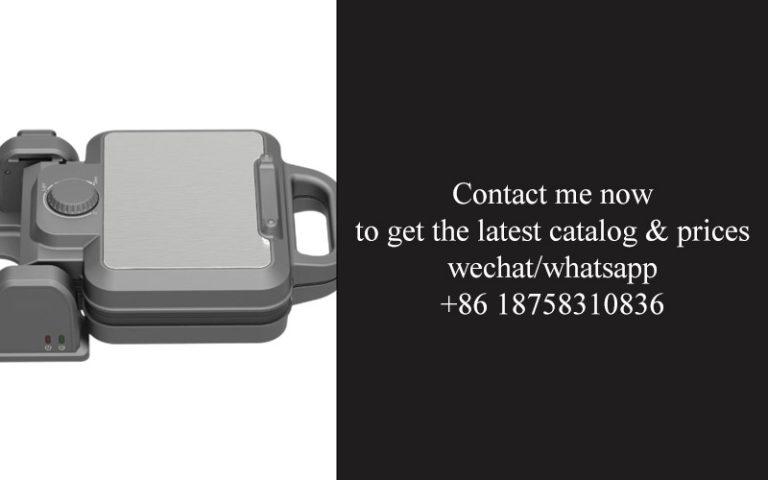

Amidst globalization’s wave, the kitchen equipment enterprise is present process terrific transformation. The advent of the -25°C bloodless-resistant model marks a enormous technological leap forward, presenting balance in severe bloodless situations. chinese language appliance corporations have evolved these appliances, enhancing substances, design, and capability for optimum low-temperature overall performance. The CIP Moscow business manufacturing unit, a frontrunner in the industry, showcases this innovation, reflecting its international presence and commitment to fashionable generation. This manufacturing unit, with its advanced manufacturing and R&D facilities, is at the vanguard of assembly the evolving desires of purchasers in harsh climates. The enterprise is trending toward intelligence, strength performance, personalization, and health, with a developing marketplace capacity in rising economies like Southeast Asia.

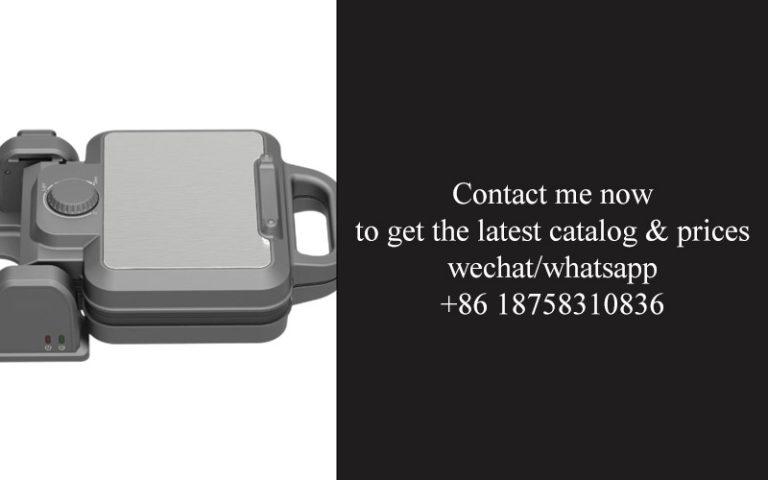

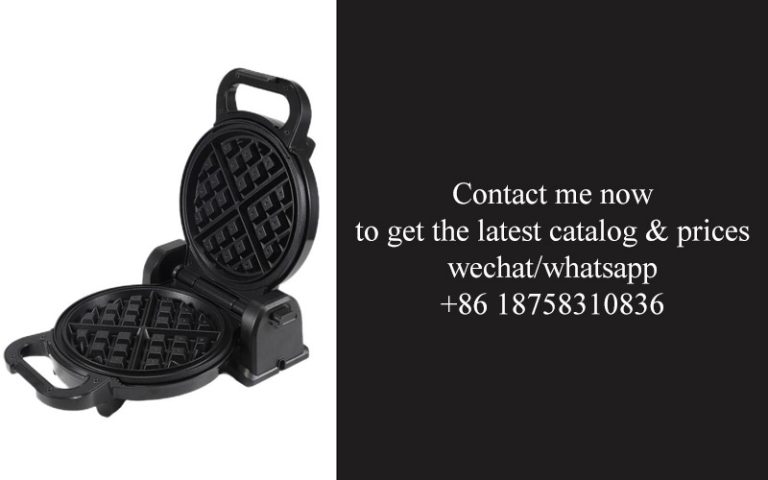

The expert Belgian waffle system is revolutionizing the kitchen appliance marketplace with its unique capabilities and health blessings. Its reputation is hovering because of the surge in demand for handy, healthy cooking options. The machine’s smart controls, multi-functional designs, and non-stick substances make it a favorite for households and eating places alike. With its emphasis on aesthetic appeal and energy efficiency, the expert Belgian waffle gadget isn’t always just a cooking tool but a elegant addition to any kitchen, catering to the developing fashion of wholesome ingesting and culinary innovation.

The Industrie-Waffeleisen manufacturers lead the global waffle iron market, constantly innovating to satisfy diverse patron needs. because the marketplace evolves, those German manufacturers are integrating clever technology, presenting multi-purposeful designs, and prioritizing health and environmental friendliness. they’re adapting to the rise of on-line sales channels and expanding into international markets, ensuring their merchandise cater to various consumer possibilities and cooking habits in towns global.

the worldwide kitchen appliance market’s fast growth has led to a growing adoption of the OEM (authentic device producer) version. This fashion is especially evident within the Gaufrier professionnel OEM area, pushed by way of the increasing call for for expert-grade ovens in industrial kitchens. The OEM model allows producers to tailor merchandise to specific patron wishes, improving marketplace competitiveness and fostering technological innovation. This collaboration with food carrier brands and inns no longer handiest deepens expertise of customer needs however also streamlines manufacturing and deliver chains. despite demanding situations like market opposition and environmental regulations, the Gaufrier professionnel OEM marketplace holds widespread capability, with producers poised to obtain a win-win state of affairs through strategic partnerships and continuous product development.