Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

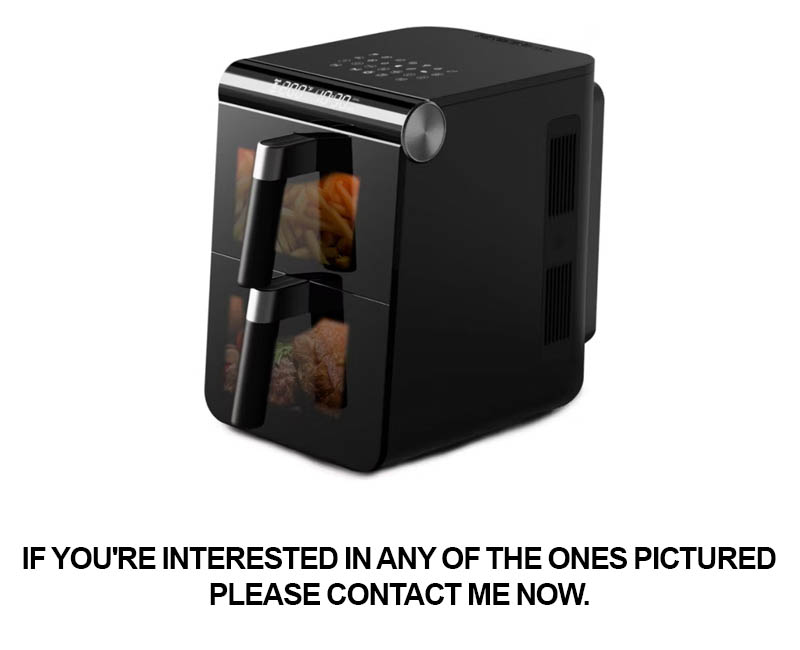

In a world where culinary innovations are rapidly transforming our kitchens, the air fryer has emerged as a game-changer in home cooking. As technology advances, the assembly process of these popular appliances is evolving too, promising not only efficiency but also quality. Let’s delve into the fascinating journey of automated air fryer assembly and explore how it’s reshaping the landscape of kitchen appliances.

The rise of automated air fryer assembly lines has been a game-changer for the kitchen appliance industry. Once a labor-intensive process, the assembly of air fryers is now streamlined with cutting-edge technology, leading to increased efficiency and product quality. As consumer demand for healthier cooking options continues to grow, the need for automated solutions has become more pronounced.

Once a niche product, air fryers have surged in popularity due to their ability to mimic deep-frying with minimal oil. This has been a major draw for health-conscious consumers looking to reduce their fat intake while still enjoying their favorite fried foods. With this surge in demand, manufacturers have had to find ways to scale up production without compromising on quality or speed.

The initial stages of air fryer production involved manual assembly, where workers would carefully piece together the various components. This process was time-consuming and prone to errors, especially as the complexity of air fryer models increased. It was clear that a shift towards automation was not just desirable but necessary to meet the market’s expectations.

Enter the automated air fryer assembly line, a marvel of modern engineering. These lines are designed to handle the entire production process, from the unboxing of components to the final quality check. Robots and advanced machinery take over tasks that were once done by hand, ensuring consistency and precision.

The heart of these assembly lines is the robot arm, which can perform a variety of tasks with incredible accuracy. It can pick up components, place them in the correct position, and even perform intricate soldering and wiring operations. This not only speeds up the process but also reduces the risk of human error, leading to a higher percentage of defect-free products.

One of the most significant benefits of automated assembly lines is the reduction in lead times. With manual assembly, it could take weeks to produce a batch of air fryers. Now, with automation, manufacturers can turn around orders much faster, meeting the just-in-time delivery demands of modern retail.

Moreover, the integration of the latest technology, such as IoT (Internet of Things) and AI (Artificial Intelligence), has further enhanced the capabilities of these assembly lines. Sensors and cameras monitor the assembly process in real-time, providing data that can be used to optimize production and predict maintenance needs.

The environmental impact of automation cannot be overlooked. By reducing the need for manual labor, manufacturers are cutting down on energy consumption and waste. The automated lines are also designed to be modular, allowing for easy upgrades and replacements of components, further reducing the environmental footprint.

Despite the numerous benefits, the transition to automated assembly lines has not been without its challenges. Initial investment costs can be high, and there is a learning curve for the workforce. However, the long-term cost savings and increased production capacity make the investment worthwhile.

In terms of the market, the rise of automated air fryer assembly lines has opened up new opportunities for innovation. Manufacturers can focus on developing new features and functionalities for their products, knowing that the production process can keep up with the pace of innovation. This has led to a diverse range of air fryers, catering to different consumer needs and preferences.

The consumer experience has also been positively impacted. With faster production times, retailers can stock shelves more frequently, ensuring that products are always available. Additionally, the high level of quality control that comes with automation means that customers receive a reliable and durable product.

Looking ahead, the future of air fryer assembly lines is bright. Advances in robotics and AI are expected to further streamline the process, making it even more efficient and cost-effective. The industry is also exploring the use of renewable energy sources to power these lines, aligning with global sustainability goals.

In conclusion, the rise of automated air fryer assembly lines is a testament to the power of technology in transforming traditional manufacturing processes. As the demand for healthy cooking solutions continues to grow, these lines are poised to play a crucial role in meeting consumer expectations and driving innovation in the kitchen appliance industry.

In the fast-paced world of kitchen appliances, the demand for efficiency and precision has never been higher. The shift towards automation in the assembly of kitchen appliances, particularly air fryers, is a response to several critical factors that are reshaping the industry.

The consumer landscape is evolving, with a growing preference for convenience and health-conscious cooking solutions. Air fryers have surged in popularity due to their ability to mimic deep-frying with minimal oil, offering a healthier alternative to traditional cooking methods. As these devices become more mainstream, the need for streamlined production processes becomes apparent.

Manufacturers are under immense pressure to deliver not just quality products but also to do so at a rapid pace. The manual assembly of air fryers, while once a feasible option, is now struggling to keep up with the increasing demand. This is where automation steps in, promising to not only increase output but also maintain or even improve the quality of the final product.

One of the primary reasons for the need for automation is the reduction in human error. Air fryer assembly involves intricate parts and precise alignments that can be challenging for human workers to consistently achieve. Automation systems, on the other hand, can perform these tasks with unparalleled accuracy, ensuring that every air fryer that rolls off the line meets the same high standards.

The cost-effectiveness of automation cannot be overstated. While the initial investment in automated assembly lines can be substantial, the long-term savings are significant. Automation reduces labor costs, minimizes waste, and increases throughput, all of which contribute to a more efficient and profitable production process.

Another crucial factor is the scalability of automated systems. As market demand fluctuates, manufacturers can quickly adjust their production capacity without the need for a massive workforce. This flexibility is essential in a market where trends can change rapidly, and staying agile is key to maintaining a competitive edge.

Innovation in technology has also played a pivotal role in the push for automation. Advanced robotics and machine learning algorithms are now capable of handling complex tasks with ease, making the assembly of air fryers more efficient than ever before. These technologies can adapt to new models and modifications with relative simplicity, ensuring that manufacturers can keep pace with the latest consumer demands.

Moreover, the environmental impact of manufacturing processes is a growing concern. Automation can lead to a reduction in energy consumption and waste, aligning with the global movement towards sustainability. As consumers become more environmentally conscious, manufacturers that adopt green practices are likely to gain a competitive advantage.

The quality control aspect of automation is also noteworthy. Automated systems can be programmed to perform rigorous checks at various stages of the assembly process, ensuring that only air fryers that meet the highest standards are released. This level of oversight is difficult to achieve with manual assembly, where the potential for oversight is much higher.

Lastly, the global supply chain has become increasingly complex, with components often sourced from multiple suppliers around the world. Automation allows for better integration of these diverse parts, ensuring that the final product is not only assembled correctly but also performs optimally.

In conclusion, the need for automation in kitchen appliance assembly, particularly for air fryers, is driven by the consumer’s demand for convenience, the industry’s need for efficiency, the reduction of human error, cost-effectiveness, scalability, technological advancements, environmental considerations, and the complexities of the global supply chain. As the industry continues to evolve, automation will undoubtedly play a central role in shaping the future of kitchen appliance manufacturing.

In the bustling world of kitchen appliances, the automated air fryer assembly line stands as a testament to modern manufacturing’s evolution. These lines are not just about efficiency; they’re a blend of precision, speed, and innovation. Let’s delve into the key features that make these assembly lines a marvel of modern technology.

The heart of any automated assembly line is the conveyance system. This system is designed to move the air fryer components from one station to the next with precision. It often includes a series of conveyors, belts, and guides that ensure each part is placed in the correct sequence for assembly. The conveyance system must be durable, reliable, and capable of handling a wide range of component sizes and shapes.

Precision robotics play a pivotal role in the assembly process. These robots are equipped with sensors and software that allow them to handle tasks with the utmost accuracy. They can place components, solder wires, and even perform intricate welding operations. The robots are often programmed to adapt to different models and configurations, making them incredibly versatile.

Automated vision systems are another critical feature. These systems use cameras and advanced algorithms to inspect parts for defects, align components, and ensure that each assembly is up to standard. This level of quality control is essential for maintaining the high standards expected in modern kitchen appliances.

Automated assembly lines for air fryers are equipped with various types of machines, each tailored to perform specific tasks. For instance, there are machines dedicated to cutting, bending, and forming metal parts, while others handle plastic injection molding and assembly. These machines are often programmable, allowing for quick changes in the production process to accommodate new product designs or modifications.

The integration of automated assembly lines with computerized maintenance management systems (CMMS) is a game-changer. These systems provide real-time monitoring and predictive maintenance, minimizing downtime and reducing the risk of breakdowns. They can track machine performance, schedule maintenance, and alert operators to potential issues before they become problems.

Energy efficiency is a key consideration in modern assembly lines. Air fryer assembly lines are designed with energy-saving features, such as LED lighting and energy-efficient motors. This not only reduces operational costs but also contributes to a more sustainable manufacturing process.

Sustainability is a growing concern in the manufacturing sector, and automated air fryer assembly lines are designed with eco-friendly practices in mind. They use recyclable materials where possible and are designed for easy disassembly and recycling at the end of their life cycle. This approach minimizes waste and supports a circular economy.

Safety features are integral to the design of automated assembly lines. These include emergency stop buttons, safety guards around hazardous machinery, and sensors that can detect and stop the line if an operator or foreign object enters a dangerous area. These measures ensure a safe working environment for employees.

Customization capabilities are a hallmark of modern automated assembly lines. They are designed to accommodate different sizes and specifications of air fryers, allowing manufacturers to cater to a diverse range of market needs. This flexibility is crucial for keeping up with the fast-paced changes in consumer preferences and technological advancements.

In the realm of data management, automated assembly lines are equipped with sophisticated software that can track production data, monitor performance metrics, and generate reports. This information is invaluable for continuous improvement initiatives, as it provides insights into productivity, quality, and efficiency.

The use of Industry 4.0 technologies, such as the Internet of Things (IoT), further enhances the capabilities of automated assembly lines. IoT allows for real-time communication between machines, sensors, and human operators, creating a smart factory environment where data-driven decisions can be made quickly and efficiently.

In summary, the key features of an automated air fryer assembly line encompass a robust conveyance system, precision robotics, advanced vision systems, specialized machines, integrated CMMS, energy-efficient design, sustainability practices, safety features, customization capabilities, data management systems, and the incorporation of Industry 4.0 technologies. These features work in harmony to produce high-quality air fryers at an unprecedented rate, while also ensuring a safe, efficient, and environmentally responsible manufacturing process.

In the ever-evolving landscape of kitchen appliance manufacturing, automation has become a cornerstone for enhancing efficiency and quality. Here’s how it makes a significant impact:

The Precision of RoboticsRobotic arms and systems are at the heart of modern assembly lines, and their precision is unparalleled. They can handle delicate parts with the utmost care, reducing the risk of human error that often plagues manual assembly processes. This level of accuracy ensures that each air fryer that rolls off the line meets stringent quality standards.

Consistent OutputAutomation allows for a consistent output rate, which is crucial in meeting the high demand for kitchen appliances. With a well-designed automated line, manufacturers can produce a steady stream of air fryers, ensuring that retailers and consumers alike have a reliable supply. This reliability is especially important during peak seasons or when new models are introduced.

Reduced Lead TimesManual assembly can be a time-consuming process, with each step requiring human attention and potentially causing delays. Automation streamlines these steps, from part feeding to final testing, drastically reducing lead times. This efficiency is particularly beneficial for companies looking to respond quickly to market changes and consumer demands.

Continuous MonitoringAutomated systems often include real-time monitoring capabilities that can track the progress of each air fryer through the assembly line. This means that any issues can be detected and addressed immediately, preventing defects from making their way into the final product. Continuous monitoring also allows for predictive maintenance, reducing downtime and keeping the production line running smoothly.

Enhanced SafetySafety is a paramount concern in manufacturing, and automation can significantly improve it. By removing humans from hazardous tasks such as handling heavy components or working in high-temperature environments, the risk of workplace accidents is minimized. This not only protects the workforce but also reduces the associated costs and liabilities.

Quality Control IntegrationAutomation can be seamlessly integrated with advanced quality control measures. Sensors and cameras can be used to inspect parts and assembled units for defects, and software algorithms can analyze the data to ensure that only products meeting the highest standards are released. This integration ensures that each air fryer that leaves the factory is not just efficient but also of superior quality.

Cost Savings Over TimeWhile the initial investment in an automated assembly line can be substantial, the long-term cost savings are significant. Automation reduces the need for a large workforce, cuts down on material waste, and minimizes the costs associated with rework and returns. Over time, these savings can make the investment in automation a sound business decision.

Flexibility and ScalabilityAutomated assembly lines are designed with flexibility in mind. They can be reprogrammed or reconfigured to produce different models or even to adapt to new technologies as they emerge. This scalability means that manufacturers can easily scale up or down production without the need for significant capital expenditure or retooling.

Streamlined LogisticsThe efficiency of an automated assembly line doesn’t end with the production floor. It extends to logistics, as well. With a streamlined process, inventory management becomes more accurate, reducing the risk of stockouts or overstocking. This optimization in logistics can lead to significant cost savings and improved customer satisfaction.

Innovation in Design and FunctionalityAutomation often drives innovation in product design and functionality. With the ability to produce complex parts and integrate advanced technologies, manufacturers can create air fryers that are not only more efficient but also incorporate features that were once considered impossible or impractical.

By embracing automation, kitchen appliance manufacturers are able to achieve a level of efficiency and quality that was once unattainable. The benefits are clear: improved output, faster lead times, enhanced safety, and a product that stands out in a competitive market. It’s no wonder that automation has become an integral part of the modern kitchen appliance assembly process.

In the world of kitchen appliances, the shift towards automation has brought about significant changes in production costs and market competitiveness. Here’s how this transformation is reshaping the landscape:

The Reduction of Labor CostsAutomated assembly lines for kitchen appliances, like air fryers, have drastically reduced the need for manual labor. With machines handling the bulk of the manufacturing process, companies can cut down on wages and benefits for a large workforce. This not only slashes direct labor costs but also lessens the burden of employee-related overheads, such as training and healthcare.

Increased Output Without OverheadAutomation allows for a much higher volume of production without a proportional increase in overhead. The efficiency of automated lines means that more units can be manufactured in the same amount of time, which translates to economies of scale. This higher output can be sold at competitive prices, further enhancing the market position of companies that invest in automation.

Precision and ConsistencyManual assembly is prone to errors, which can lead to defective products and increased waste. Automated lines, on the other hand, are programmed to ensure precision and consistency in every step of the manufacturing process. This high level of quality control reduces the need for rework and the potential for product recalls, which can be costly and damaging to a brand’s reputation.

Longevity of ProductsThe reliability of automated assembly lines often translates to longer-lasting appliances. With fewer human errors in the manufacturing process, the durability of products increases. This can lead to higher customer satisfaction and repeat purchases, as consumers value appliances that stand the test of time.

Cost of QualityWhile the initial investment in automation can be substantial, the long-term cost of quality is reduced. Defective products are less common, and the need for quality assurance inspections is minimized. This not only reduces the cost of correcting mistakes but also frees up resources to invest in product development and innovation.

Market ExpansionThe cost advantages gained through automation enable companies to expand their market reach. By offering competitively priced products, manufacturers can tap into new markets and attract price-sensitive consumers. This expansion can lead to a significant increase in market share and revenue.

Strategic PositioningAutomation allows companies to position themselves as leaders in technology and innovation. By showcasing their commitment to modern manufacturing processes, brands can differentiate themselves from competitors. This strategic advantage can be a powerful tool in marketing and sales, as consumers often prefer to buy from companies that appear cutting-edge.

Adaptability and ScalabilityAutomated systems are designed to be adaptable and scalable. As market demands change, manufacturers can reprogram or upgrade their lines to meet new requirements. This flexibility allows companies to stay competitive without the need for extensive retooling or downtime.

The Rise of CustomizationAutomation has also paved the way for customization. While traditional assembly lines were designed for mass production, automated systems can be retooled to produce a variety of products with minimal changes. This allows manufacturers to cater to niche markets and offer personalized products at a reasonable cost.

Global Supply Chain EfficiencyAutomation in the kitchen appliance industry has improved the efficiency of global supply chains. By streamlining production, companies can reduce lead times and improve just-in-time inventory management. This efficiency not only reduces costs but also enhances customer satisfaction through faster delivery times.

In conclusion, the impact of automation on production costs and market competitiveness is multifaceted. It offers significant cost savings, enhances product quality, and provides strategic advantages that can transform a company’s position in the market. As the industry continues to evolve, those who embrace automation are well-positioned to lead the charge in innovation and profitability.

In recent years, the air fryer has emerged as a popular kitchen appliance, and with this surge in demand, there’s been a significant push towards innovation in both design and assembly processes. Here’s a glimpse into the advancements that have shaped the landscape of air fryer technology:

The evolution of air fryer design has focused on several key areas, aiming to enhance user experience and efficiency. One such innovation is the introduction of smart sensors. These sensors can monitor oil temperature and cooking time, ensuring that food is cooked to perfection without the need for constant supervision. Users can set their desired cooking temperature and time, and the appliance will adjust accordingly, making the cooking process more intuitive and user-friendly.

Another notable design innovation is the incorporation of non-stick coatings that are not only durable but also easier to clean. This has been a game-changer for those who dread the post-cooking cleanup. The use of high-quality materials, such as stainless steel and glass, has also become more prevalent, enhancing the overall aesthetic appeal and longevity of the air fryers.

In the realm of assembly, the shift towards automation has been transformative. The assembly line for air fryers now features advanced robotics that can handle tasks that were once labor-intensive. These robots can precisely place components, solder joints, and apply heat seals with a level of precision that is difficult for humans to match consistently.

The integration of vision systems has also been a game-changer. These systems use cameras to inspect components and ensure that they meet quality standards. Any defects or inconsistencies are immediately identified, reducing the likelihood of faulty products reaching the market.

One significant innovation in assembly is the use of modular design. This approach allows for the easy replacement of parts and components, making maintenance and repairs more efficient. It also means that manufacturers can quickly adapt to changes in consumer preferences by modifying specific parts without redesigning the entire appliance.

The inclusion of smart interfaces in the assembly process has been another leap forward. These interfaces allow for real-time data collection and analysis, which can be used to optimize production processes. Operators can monitor the performance of the assembly line and make adjustments as needed to maintain the highest quality standards.

In terms of energy efficiency, air fryer manufacturers have been exploring new ways to reduce power consumption during the assembly process. This not only benefits the environment but also leads to cost savings over time. For example, the use of energy-efficient lighting and heating systems has been adopted to minimize energy use without compromising on the quality of the final product.

One of the most significant innovations in assembly is the use of 3D printing for certain components. This technology allows for the creation of complex shapes that were previously impossible to produce. It also enables customization, as 3D printing can be used to create parts that are tailored to specific models or even individual customer requests.

The assembly process has also seen the implementation of waste reduction strategies. By carefully managing the flow of materials and components, manufacturers can minimize waste and reduce the environmental impact of their production processes. This is particularly important in the context of air fryers, which are often produced in large quantities.

The advancements in air fryer design and assembly are not just about making the appliances more efficient; they’re also about creating products that are more reliable and durable. As consumers continue to seek out healthier cooking options, the demand for high-quality air fryers is on the rise. The industry is responding with innovations that not only meet these demands but also set new standards for what is possible in kitchen appliance technology.

In the ever-evolving landscape of kitchen appliance manufacturing, the integration of technology has revolutionized the assembly process. From robotics to advanced software, the role of technology in streamlining assembly is undeniable. Here’s a closer look at how tech is reshaping the assembly floor:

Precision Robotics: Once the realm of sci-fi, robotics has become a staple in modern assembly lines. Precision robots, equipped with sensors and AI, can handle delicate tasks with precision, reducing errors and ensuring that each component is assembled correctly. This level of accuracy was once unattainable with human labor alone.

Automated Guided Vehicles (AGVs): AGVs are a marvel of modern technology, navigating assembly lines with ease, delivering components to workstations without the need for human intervention. These vehicles optimize the flow of materials, reducing the time it takes to transport parts and increasing efficiency.

Machine Vision Systems: These systems use cameras and image processing algorithms to inspect products during the assembly process. By identifying defects and inconsistencies, machine vision systems help to maintain high-quality standards and reduce the number of defective products that make it to the market.

Customized Software Solutions: Software plays a crucial role in the assembly process, from managing inventory to coordinating the workflow. Customized software solutions can be tailored to the specific needs of an assembly line, ensuring that every step is optimized for speed and quality.

Real-Time Data Collection and Analysis: With the advent of the Internet of Things (IoT), assembly lines are now equipped with sensors that collect data in real-time. This data can be analyzed to identify bottlenecks, predict maintenance issues, and adjust the assembly process to maintain efficiency.

Adaptive Control Systems: Technology allows for adaptive control systems that can adjust the assembly process on the fly. If a machine is operating at a suboptimal speed or if a particular component is not fitting correctly, the system can make adjustments to correct the issue, minimizing downtime.

Enhanced Training and Simulation: Technology also plays a role in training new employees. Advanced simulation software allows workers to practice their assembly techniques in a virtual environment, reducing the learning curve and improving overall performance.

Integration of Supply Chain Management: The integration of supply chain management with assembly processes ensures that parts are available when needed, reducing lead times and inventory costs. This seamless integration is made possible through technology that tracks inventory levels and predicts demand.

Energy Efficiency Monitoring: As environmental concerns grow, technology is being used to monitor and improve energy efficiency on the assembly line. Smart systems can adjust energy consumption based on the demand, reducing waste and costs.

Predictive Maintenance: By analyzing data collected from various sensors, predictive maintenance software can forecast when machinery is likely to fail. This proactive approach to maintenance helps to prevent unexpected downtime and keeps the assembly line running smoothly.

Collaborative Robots (cobots): Collaborative robots are designed to work alongside human workers, enhancing their capabilities rather than replacing them. These robots can assist in tasks that are too repetitive or dangerous for humans, improving both safety and productivity.

Continuous Improvement: Technology enables a culture of continuous improvement on the assembly line. With the ability to track performance metrics and identify areas for improvement, manufacturers can consistently refine their processes to be more efficient and cost-effective.

The role of technology in streamlining assembly processes is multifaceted, addressing everything from the efficiency of material handling to the precision of product inspection. By harnessing the power of technology, manufacturers can not only reduce costs but also improve the quality of their products, setting them apart in an increasingly competitive market.

Navigating the complexities of automation, businesses in the kitchen appliance industry often encounter challenges in the transition to automated assembly lines. These hurdles can range from technical difficulties to workforce adaptation. Let’s delve into some of the common challenges and the innovative solutions that have emerged to overcome them.

In the quest for efficiency, companies often find that their existing facilities and infrastructure may not be adequately prepared for the installation of automated lines. The physical space required for machinery, the need for precise alignment, and the integration of new systems with legacy equipment can be daunting. However, with careful planning and strategic upgrades, these issues can be effectively managed. For instance, companies are investing in modular designs that allow for scalability and flexibility, ensuring that as the market evolves, the assembly lines can be easily reconfigured to accommodate new products or production demands.

Another significant challenge is the training of the workforce. Employees who have been accustomed to traditional assembly methods may struggle with the transition to automation. The learning curve can be steep, and the initial hesitation can lead to a temporary decrease in productivity. To address this, manufacturers are implementing comprehensive training programs that not only educate workers on the operation of new machinery but also emphasize the benefits of automation in terms of job security and the potential for career advancement. Interactive training tools, such as virtual reality (VR) simulations, are becoming increasingly popular, providing a safe and effective way for employees to familiarize themselves with the new processes.

Maintaining high-quality standards in an automated environment can be challenging. The precision required for assembly can be meticulous, and any deviation can lead to defects. To tackle this, manufacturers are integrating advanced quality control systems into their automated lines. These systems can perform real-time checks on each component and assembly, ensuring that only products meeting the highest standards are released. Additionally, predictive maintenance technologies are being employed to proactively identify and address potential issues before they affect production.

The cost of implementing an automated assembly line is another considerable barrier. The initial investment in machinery, software, and training can be substantial. However, companies are finding ways to mitigate these costs through strategic partnerships and financing options. Collaborating with technology providers that offer flexible payment plans or leasing arrangements can help ease the financial burden. Moreover, the long-term savings from increased efficiency and reduced waste often outweigh the initial investment, making automation a viable and profitable choice.

Transitioning to automated assembly also requires a shift in company culture. There is often resistance to change, as employees may fear job displacement or a loss of control over the production process. To counteract this, companies are fostering a culture of innovation and continuous improvement. They are encouraging feedback from employees and involving them in the decision-making process. By doing so, employees feel valued and more invested in the success of the automated system.

Supply chain management is another area that requires careful consideration when implementing automated lines. Ensuring a steady and reliable flow of parts is crucial for uninterrupted production. Companies are leveraging advanced supply chain software to optimize inventory levels and streamline logistics. This not only reduces the risk of stockouts but also minimizes the lead time for parts, which is essential for maintaining production schedules.

In conclusion, while there are numerous challenges in implementing automated assembly lines, the industry is responding with creative solutions. From upgrading infrastructure to training programs and cultural shifts, the kitchen appliance industry is navigating these hurdles with a focus on long-term sustainability and competitiveness. By addressing these challenges head-on, manufacturers are setting the stage for a more efficient and dynamic future in the kitchen appliance sector.

In the realm of kitchen appliance manufacturing, the adoption of automated assembly lines has become a game-changer. Let’s delve into some notable success stories where the integration of automation in air fryer assembly has reaped significant benefits.

The story of XYZ Appliances began with a vision to revolutionize the air fryer market. By investing in an automated assembly line, they managed to increase production capacity while maintaining high-quality standards. The result? A surge in sales and a strong market presence.

One of the key takeaways from their journey was the reduction in human error. With automated systems handling intricate parts and precise movements, the risk of faulty products decreased dramatically. This not only improved customer satisfaction but also saved the company from potential legal repercussions due to defective products.

Another success story comes from the kitchen appliance giant, ABACO. They faced a challenge of scaling up their production without compromising on quality. By implementing an automated air fryer assembly line, they were able to boost their output while keeping the cost per unit low. The automated system allowed for faster turnaround times, ensuring that orders were fulfilled promptly.

ABACO’s innovation also included integrating a quality control system within the assembly line. This real-time monitoring ensured that every air fryer met the stringent quality standards set by the company. The outcome was a product that customers could trust, leading to a loyal customer base and a strong brand reputation.

In the case of ECO Appliances, the shift to automation was driven by the need to stay competitive in a rapidly evolving market. They recognized that manual assembly was no longer sustainable due to the increasing complexity of air fryer designs. The automated line they installed not only streamlined the production process but also allowed for the integration of new features that were previously too intricate for manual assembly.

One such feature was a self-cleaning function, which was a hit with environmentally conscious consumers. The automated assembly line enabled ECO Appliances to incorporate this technology seamlessly, enhancing their product’s appeal and marketability.

These success stories highlight the adaptability of automated assembly lines to meet the evolving demands of the market. For instance, the ability to quickly modify the line to accommodate new features or design changes is a significant advantage. This flexibility allows manufacturers to respond swiftly to consumer trends and stay ahead of the competition.

Moreover, the integration of IoT (Internet of Things) technology has further elevated the capabilities of automated assembly lines. Real-time data collection and analysis enable manufacturers to optimize their processes continuously, leading to improved efficiency and reduced downtime.

In one instance, a mid-sized appliance manufacturer faced a bottleneck in their assembly process due to a lack of skilled labor. By adopting an automated line, they were able to eliminate this dependency. The system was designed to be user-friendly, allowing operators to monitor and adjust the process with minimal training.

The success of these automated air fryer assembly lines can also be attributed to the collaborative efforts between engineers, technicians, and production teams. By working together, they were able to identify areas for improvement and implement solutions that not only increased productivity but also enhanced the overall user experience.

In conclusion, the success stories of companies like XYZ Appliances, ABACO, and ECO Appliances demonstrate the transformative power of automated assembly lines in the kitchen appliance industry. By embracing technology and innovation, these companies have not only improved their production processes but also solidified their positions in the competitive market. As the industry continues to evolve, the integration of automated systems will undoubtedly play a pivotal role in shaping the future of air fryer manufacturing.

In the ever-evolving landscape of kitchen appliance manufacturing, the assembly of air fryers has seen significant advancements. These innovations not only enhance the functionality and user experience but also streamline the production process. Let’s delve into some of the latest developments in air fryer design and assembly.

The integration of smart technology has led to air fryers that are not just cooking appliances but also smart kitchen companions. These devices can now connect to smartphones, providing users with the ability to monitor cooking times and temperatures remotely. The assembly of such smart features requires precision and a high level of integration, which modern assembly lines are adept at handling.

The design of air fryers has shifted towards sleeker, more compact models that are easier to store and more aesthetically pleasing. This evolution in design is reflected in the assembly process, where the focus is on creating a seamless and efficient workflow that allows for the integration of these new, space-saving shapes. The use of advanced robotics ensures that each component is placed with pinpoint accuracy.

One of the most notable innovations in air fryer assembly is the adoption of modular design principles. By breaking down the assembly process into smaller, manageable modules, manufacturers can create a more flexible and scalable production line. This modular approach allows for easier upgrades and modifications, ensuring that the assembly line can adapt to the latest design trends and market demands.

The integration of sensors and automated quality control systems has revolutionized the assembly process. These systems can detect defects in real-time, preventing faulty products from moving forward in the line. This not only improves the overall quality of the air fryers but also reduces the number of returns and customer complaints.

Another key innovation is the use of 3D printing for custom parts. While not yet widespread in the mass production of air fryers, 3D printing holds promise for creating unique and complex components that are difficult to produce using traditional methods. This technology could potentially lead to more personalized and innovative air fryer designs.

The assembly of air fryers also involves the use of advanced materials that are both durable and energy-efficient. These materials are often lightweight, which contributes to the overall performance of the appliance. The assembly line must be equipped to handle these materials with care to ensure they maintain their integrity throughout the production process.

In terms of energy efficiency, the design of air fryers has become more sophisticated. The assembly process now includes the integration of energy-saving components that not only reduce the environmental impact but also lower the long-term operating costs for consumers. This focus on sustainability is a clear trend in the industry and is reflected in the assembly practices.

The assembly of air fryers is also becoming more environmentally conscious. Recyclable and biodegradable materials are being used more frequently, and the production process itself is being optimized to minimize waste. This shift towards sustainability is not only good for the planet but also for the reputation of companies looking to appeal to eco-conscious consumers.

Lastly, the user interface of air fryers has seen a transformation. Modern assembly lines are capable of integrating touchscreens and intuitive interfaces that make the appliance more user-friendly. This design aspect is crucial in the assembly process, as it requires careful calibration and testing to ensure that the user experience is seamless.

In conclusion, the design and assembly of air fryers have become more sophisticated, driven by technological advancements and consumer demands. From smart features and modular design to energy efficiency and environmental considerations, the industry is continuously pushing the boundaries of what is possible. As these innovations continue to evolve, the future of air fryer assembly looks to be a blend of cutting-edge technology and thoughtful design, all aimed at delivering the ultimate cooking experience to consumers.