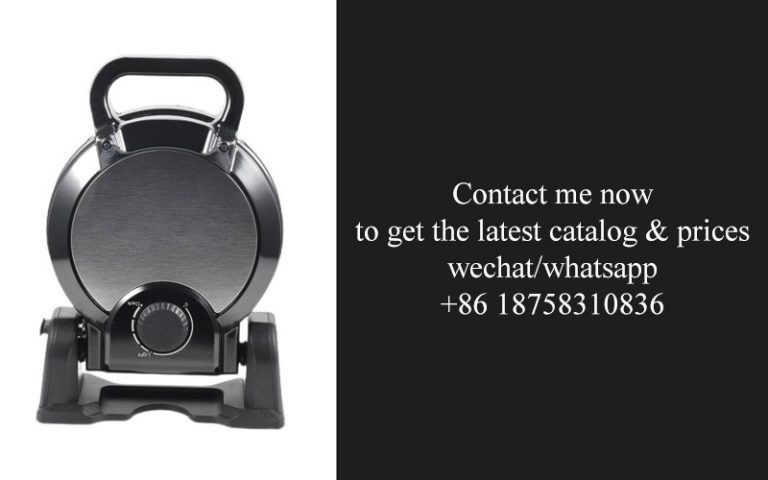

The rise of the industrial waffle maker has revolutionized commercial kitchens, offering 220V appliances with enhanced efficiency and features. These machines are not just robust but also incorporate smart technology, including adjustable temperature controls and timers, ensuring consistent waffle quality. With features like automatic shut-offs and energy-efficient designs, these industrial waffle makers are a staple for busy cafes, hotels, and event venues. The integration of advanced technology continues to expand, making these appliances not only efficient but also versatile, catering to diverse culinary needs and dietary preferences.

Private label kitchen appliance packaging has become increasingly crucial in the competitive market, as it not only protects the product but also shapes consumer perception and brand identity. Key features of effective packaging include standout design, functionality, sustainability, and clear information. This is especially important for Private Label brands aiming to differentiate themselves from established appliance manufacturers. Features like eco-friendly materials, interactive elements, and customization are gaining traction, enhancing user experience and fostering brand loyalty. As the kitchen appliance industry evolves, innovative packaging solutions will continue to play a pivotal role in the success of Private Label brands.

The ODM juicer design service has become a cornerstone in shaping the modern juicer market, offering features like sleek aesthetics, advanced technology, and user-friendly functionality. By leveraging ODM, manufacturers ensure their appliances stand out with features such as variable speeds, smart connectivity, and durable construction. The integration of cutting-edge technology, such as digital displays and energy-efficient motors, not only enhances the juicing experience but also aligns with the growing demand for smart and sustainable appliances. ODM services guarantee that each juicer is not just a product but a testament to innovation and quality, ensuring a sure bet in the competitive appliance industry.

In the era of technology and convenience, the small appliance market has seen a significant surge, with drop shipping from China emerging as a compelling opportunity for entrepreneurs. Leveraging China’s vast manufacturing capabilities, manufacturers offer cost-effective production and a wide array of products, making it an attractive choice for drop shipping ventures. This model not only provides access to a diverse range of appliances but also ensures fast production and delivery times, contributing to the sure success of businesses in this dynamic market.

In today’s culinary-centric world, the air fryer has emerged as a versatile and health-forward appliance, reshaping kitchen landscapes. As a leading Amazon FBA supplier for air fryers, we offer top-notch products that cater to the burgeoning demand. Our air fryers are a game-changer, delivering crispy fried results with significantly less oil, making them a favorite among health-conscious consumers and busy home cooks. With our efficient order fulfillment, quality assurance, and tailored branding options, we ensure your success in the market, simplifying the cooking experience and enhancing your kitchen’s efficiency. Partner with us to leverage the air fryer trend and take advantage of our expertise in this dynamic industry.

In the evolving kitchenware market, BSCI audited factories are leading the charge with high-quality, ethical production. These factories prioritize both form and function, offering innovative appliances that revolutionize cooking experiences. From smart kitchen scales to eco-friendly cookware, technology integration ensures convenience and efficiency. The rise of such factories reflects a market shift towards sustainable, durable, and personalized cooking tools, ensuring that every meal is not just a meal but a delightful culinary adventure.

In the evolving kitchen appliance industry, Walmart-approved suppliers are leading the charge with innovative gadgets that redefine cooking experiences. These suppliers, recognized for their quality and innovation, offer a wide array of appliances that seamlessly blend technology and convenience. From smart toasters that connect to smartphones to induction cooktops that provide precise heat control, these appliances enhance cooking efficiency and enjoyment. The focus on sustainability and smart design further underscores the commitment to a modern, eco-conscious kitchen. Walmart’s rigorous selection process ensures that these suppliers meet high standards, making them a trusted choice for consumers seeking cutting-edge kitchen appliances.

Navigating the vast array of air fryer manufacturers can be challenging, but finding a reliable supplier is crucial for your business. To ensure you’re not just getting a product but a long-term partnership, look for a factory that excels in quality control, innovation, and compliance. Seek out manufacturers with advanced production techniques, certifications like ISO and CE, and a strong track record of customer satisfaction. Don’t forget to check their market reputation, scalability, and environmental responsibility. By thoroughly researching and visiting potential suppliers, you can confidently select an air fryer factory that aligns with your business goals and standards.

In the evolving kitchen appliances sector, the rise of import substitution programs has empowered local suppliers to revolutionize the market. These suppliers, driven by technological advancements and consumer demands, are crafting appliances that not only cater to the evolving preferences of European and American consumers but also support local economies. By focusing on innovation and leveraging local resources, they are offering high-quality, cost-effective alternatives to imported goods. This shift, fueled by manufacturers’ commitment to quality and sustainability, is reshaping the landscape of kitchen appliances, making them more accessible, efficient, and tailored to the needs of today’s homeowners.

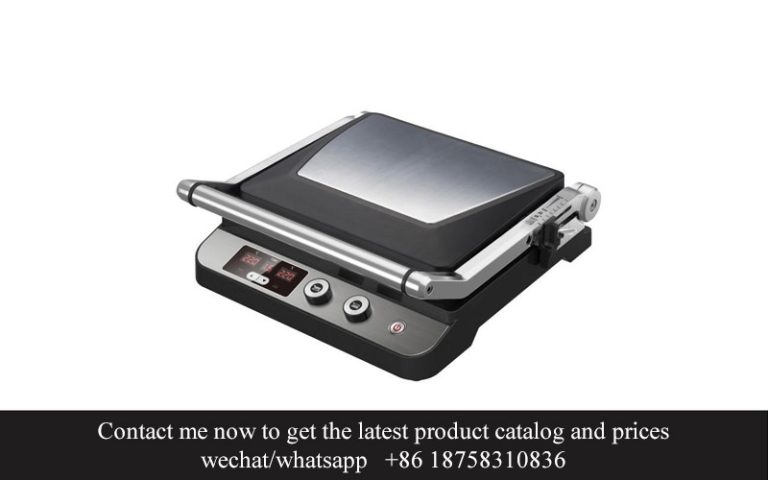

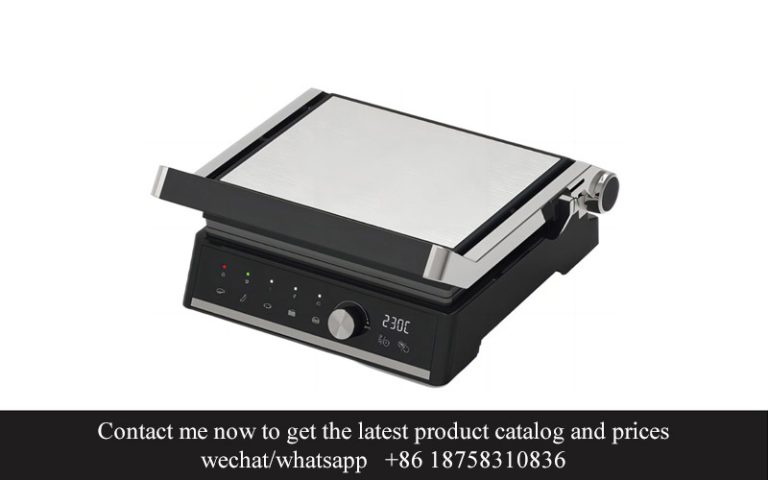

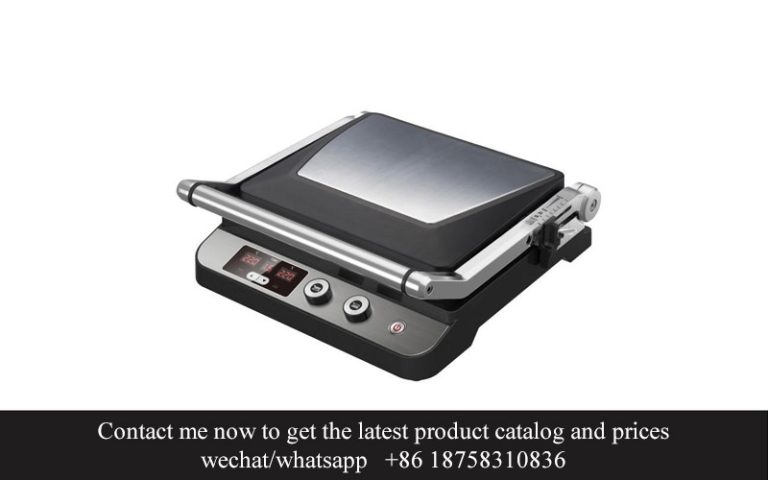

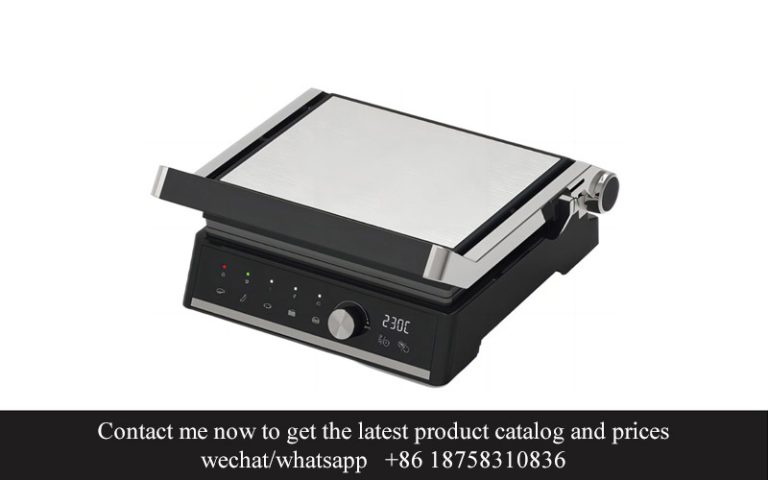

The ideal contact grill for your kitchen should boast a robust 3-year warranty, showcasing the manufacturer’s confidence in its durability. Key features to seek include even heat distribution, non-stick surfaces for effortless cooking, and adjustable temperature settings for precision. A large cooking surface, removable parts for easy cleaning, and safety features like automatic shut-off are also essential. Look for a model that complements your kitchen’s style, offers versatility in cooking, and is from a reputable manufacturer known for quality and innovation. These attributes make the contact grill not just a tool but a valuable kitchen companion.